On 28 October the NLR — Netherlands Aerospace Centre signed a public-private partnership agreement with Fokker, Embraer and Wärtsilä. The Delft University of Technology and the Royal Netherlands Air Force are also involved in the partnership. The objective of the project “Prediction of fatigue in engineering alloys (PROF)” is to improve the prediction of fatigue in aluminium and steel alloys and to transfer new insights on fatigue to industrial companies.

The worldwide annual loss of engineering components and structures due to fatigue is estimated to be billions of dollars. New fundamental insights on the behavior of fatigue can contribute to the development of material with improved resistance to fatigue and the extension of the life of aging components and structures. The life of aircraft structures is determined by an increase in the chance of failure by fatigue. By accurate predictions of fatigue the life of the aircraft can be extended, which contributes to a sustainable use of energy and raw materials.

The four year project is part of the Materials Transition Program that was initiated by the government of the Netherlands to make the material knowledge that is present at NLR and TNO more accessible for industry. Fatigue plays an important role in the aerospace industry and much knowledge has been gained that can also be used in other industrial sectors. NLR and Delft University of Technology have always been important players in the field of fatigue research, however in the last 25 years there has been little worldwide progress in fundamental insights on fatigue crack growth.

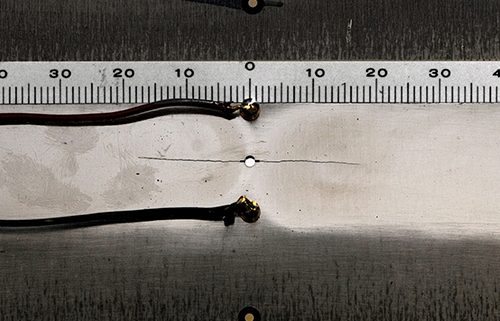

In the project the NLR will perform accurate measurements of crack growth in aluminium and steel alloys that have to result in a better physical model of fatigue. The measurements will be performed at different length scales. Fatigue cracks are usually small for a long period of time and determining the crack growth rate of small crack is therefore important for the life prediction. The scanning electron microscope will be used to measure the crack growth rate for these small cracks. Subsequently, fatigue tests will be performed to measure the influence of the environment and variable loads. To model the effect of variable loads on fatigue a PhD position will be available at the Delft University of Technology. The total research budget of 675 k€, but this can still increase because the project is still open for new industrial companies that would like to join.