Operational availability of materiel – background interview

Better, faster and cheaper maintenance all improve the availability of aircraft and helicopters. New technology such as digital twinning and artificial intelligence is playing an important role in this. The NLR’s Operational availability of materiel knowledge programme is carrying out a lot of research into this, for both civil and military aviation. “We’re doing this in collaboration with aerospace companies and the Defence Department,” says John Dominicus, the programme leader.

“Smart maintenance improves the availability of aircraft”

– Programme leader John Dominicus

What does the knowledge programme involve?

“If aviation is to function properly, both the civil and the military sides, it’s important that planes and helicopters are available enough of the time. If aircraft break down or if components can’t be delivered, it reduces the availability figure. In this programme, we investigate how that availability can be improved, for instance using new technologies.”

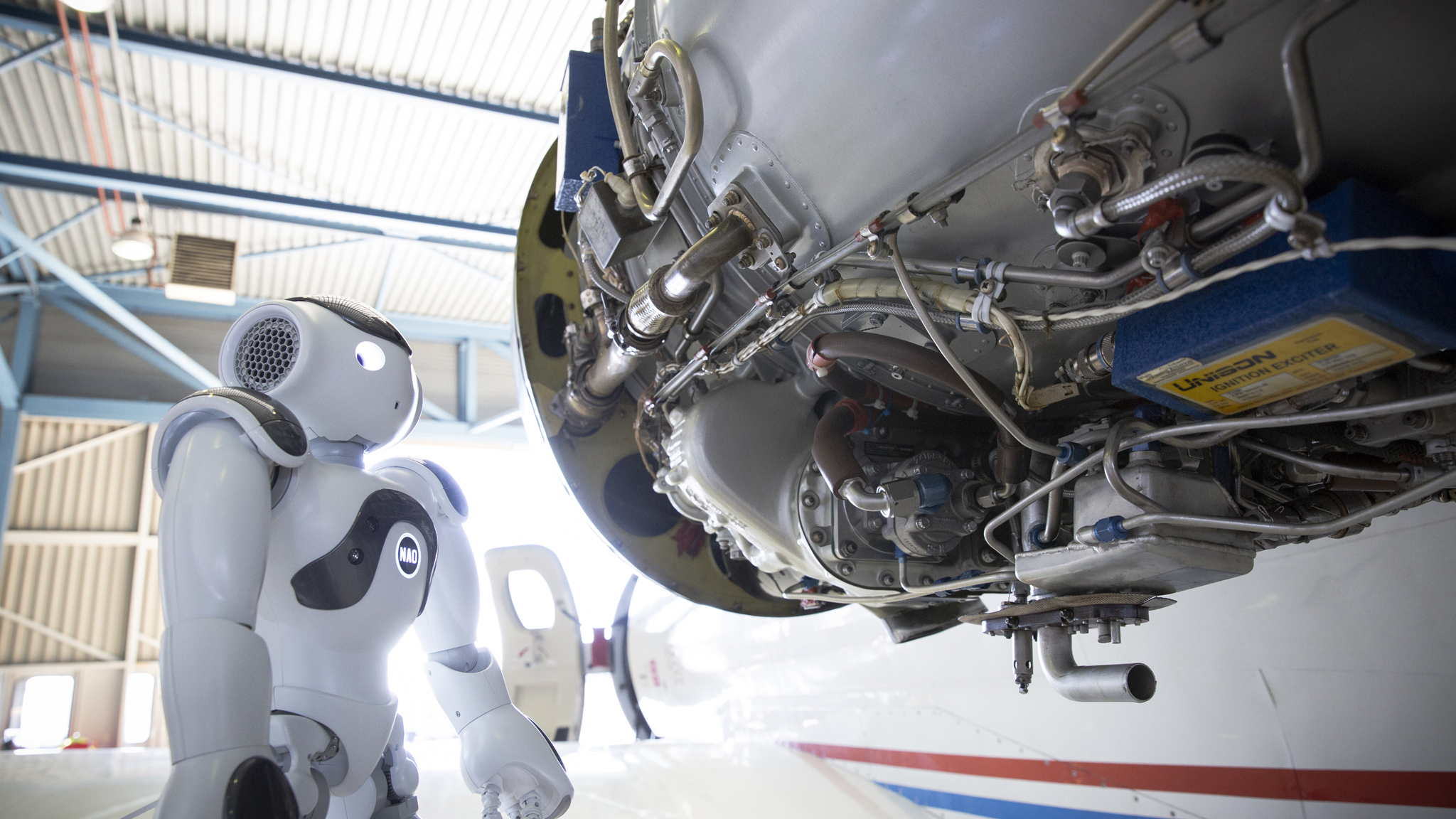

“We’re researching the options for automation and robotisation, for example. That’s because plane and helicopter maintenance is in fact largely done manually at the moment, which makes it a costly activity. On top of that, finding staff to carry out the work is becoming increasingly challenging in this tight labour market. Robots could be one element of the solution.”

Strategic programme: Operational availability of materiel

The programme wants to contribute to the optimisation of the material availability and the cost effective use of aircraft, helicopters, drones, wind turbines and other complex systems. Through this, we help to improve the operational effectiveness of the armed forces and the competitive position of businesses.

Click on the visual to enlarge.

What impact will the programme have on society?

“There are three aspects to the social importance of good operational availability. First of all, there are the economic interests. If parties such as KLM can do maintenance more cost-efficiently, it improves their competitive position with respect to other aerospace companies. Secondly, it’s important that society should be kept safe. We want to help the air force operate more effectively thanks to greater availability of their aircraft. Finally, we play a part in making society greener by combating waste and making maintenance more sustainable.”

A good example of the support we provide for the air force is a setup for inspecting helicopter rotor blades at the air force base in Woensdrecht. As yet, inspecting rotor blades has been time-consuming, manual work: someone taps the rotor with a small hammer and listens to the sounds to detect hidden defects. Every square centimetre of a blade nine metres long and one metre wide has to be inspected this way. We’ve automated that process: the rotor blade is suspended in a cradle and measured using sensors to uncover any defects. This automated process is much quicker than the manual process, which means that the helicopter is ready to be deployed again sooner.”

Predictive maintenance

“Another important topic is predictive maintenance. If we’re smart about doing the measurements, we can make predictions at a given point about the maintenance requirements for planes and helicopters. At the moment, aircraft maintenance is done after a fixed number of hours that is defined in advance, much like the servicing schedule for a car. We want to look a step beyond this type of periodic maintenance.

“Measuring the parts and components individually using sensors lets keep a close eye on their quality. That lets us determine when maintenance is genuinely needed or when the parts have reached the end of their service life and need replacing. That makes it quite a bit more efficient and therefore cheaper because it becomes easier to cluster the maintenance activities, for example. On top of that, it generates useful savings in materials, of course. We then only do the maintenance when it’s really needed, which is an environmental gain as well.”

Additive manufacturing

“On top of that, we at NLR are getting more and more into additive manufacturing. That means that we’re able to make metal parts using a 3-D printer. That means less waste during production and less stock is needed. That helps combat waste too.”

What is NLR’s role in all this?

“NLR carries out applied research. We have knowledge and expertise in-house about a wide range of topics and we make that know-how available for companies and for the government. It’s interesting for us to work with the industry and with the users. That lets us know what issues they’re coming up against and tells us the best way to let our innovations fit in with the actual practice. That cross-pollination is massively valuable.”

“Implementing new technologies isn’t so straightforward, though. On the one hand, aviation is high-tech and there’s plenty of scope for new technology and new materials. On the other, it’s a sector that is also very conservative; that’s because of the safety requirements, of course. New components and technologies have to be proved to be reliable. We can’t achieve that with a single programme, naturally, and we work a great deal with other programmes within NLR. There’s a link with Aerospace vehicle development, for instance, as a programme that focuses largely on the development of flight, where maintenance is involved. For military aviation, there are links too with the programmes Information readiness and operations, Future Airpower, Systems & Personnel and Unmanned and Autonomous. We’d like to be able to use drones in future for inspecting aircraft.

“Artificial intelligence is going to become more and more important in data analysis”

What will the programme be concentrating on in the coming time?

“Predictive maintenance is an important dot on the horizon. A variety of projects are working towards that. It means that we’re taking a step-by-step approach to implementing sensors and analysing data. We’re getting capable of producing a better picture of a plane’s condition and that means we can make increasingly accurate predictions.”

“I also think that artificial intelligence is going to become more and more important in data analysis. In the longer term, I believe we’ll be able to make smarter models and that will yield better predictions. Complementary to that, I expect that sensors will be built into the aircraft to an increasing extent. That’s already being done, but because the sensors are becoming cheaper, it will be possible to expand that further in future. That makes it easier to collect and analyse data.”

About the programme leader

John Dominicus is an aerospace engineer, project leader and the programme leader of the Operational availability of materiel programme.

John has gained extensive experience within multiple divisions at NLR and has gained broad knowledge of our organisation from various roles. “In my work I mainly work with customers and specific assignments to support them as best as possible. I do my part together with colleagues to optimise deployment readiness.”