The challenge

Rotor blade designs have to be sufficiently strong for wind tunnel testing and must have dynamic characteristics that resemble the full-scale behaviour. This implies that the blade design should have a closely matching stiffness and mass distribution along its entire span in comparison with the target properties of the aeroelastically scaled blades.

- Stiffness properties along the blade span:

- Axial, flap and lead-lag bending, and torsion stiffness

- Location of the neutral axis and shear centre

- Mass properties along the blade span:

- Mass and mass moments of inertia

- Centre of gravity position

In addition, the blades have to be instrumented for monitoring the loads and dynamic behaviour of the blades during the wind tunnel test.

The solution

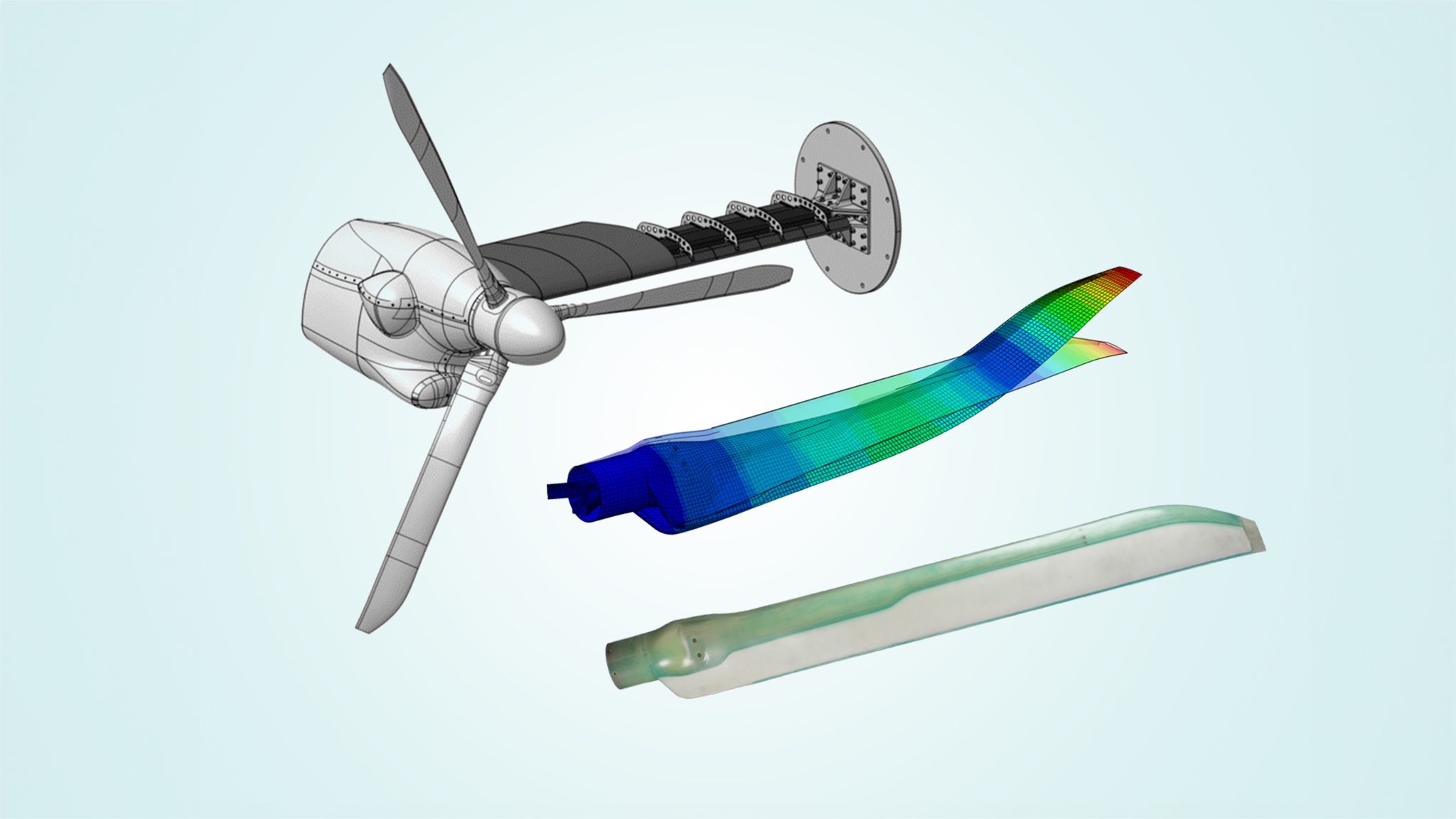

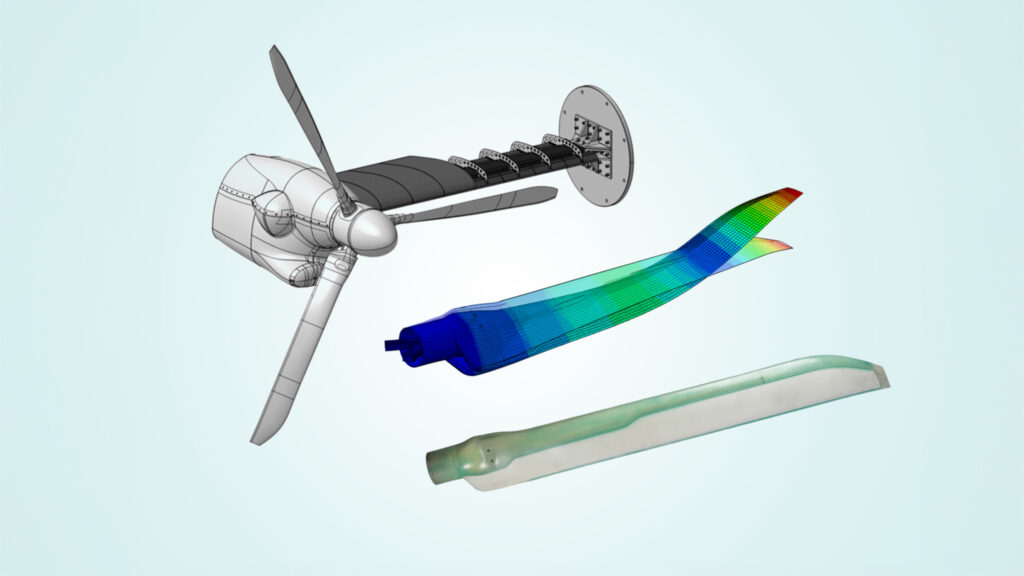

The blade design consists of a load-carrying D-spar and separate (thin) trailing edge. Both are constructed from glass fibre-reinforced laminates supported by an internal foam core. In addition, the D-spar has tungsten bars of varying lengths and diameters; these non-structural masses are used for tuning the mass distribution and CoG position along the span of the blade. The final design of the blade is based on detailed FEM analyses to determine the cross-sectional stiffness properties along the blade span. These properties were tuned to the required values by varying the lay-up in the different segments (nose, top/bottom skin, web, trailing edge) for each blade cross-section. It turned out that the blade needs to be very flexible towards the tip. The low required stiffness properties necessitate the application of ultra-thin glass fibre fabric plies (47 gsm). These thin plies also allow accurate tuning of all the different stiffness properties in the rest of the blade.

What did we do?

Aeroelastically scaled blades were designed and manufactured. The design encompassed everything from conceptual design to detailed stress analysis of the final blade structure. The final blade design has closely matching stiffness

and mass distributions, while still satisfying all wind tunnel strength/safety requirements.

Read more about the ATTILA project on the project website.

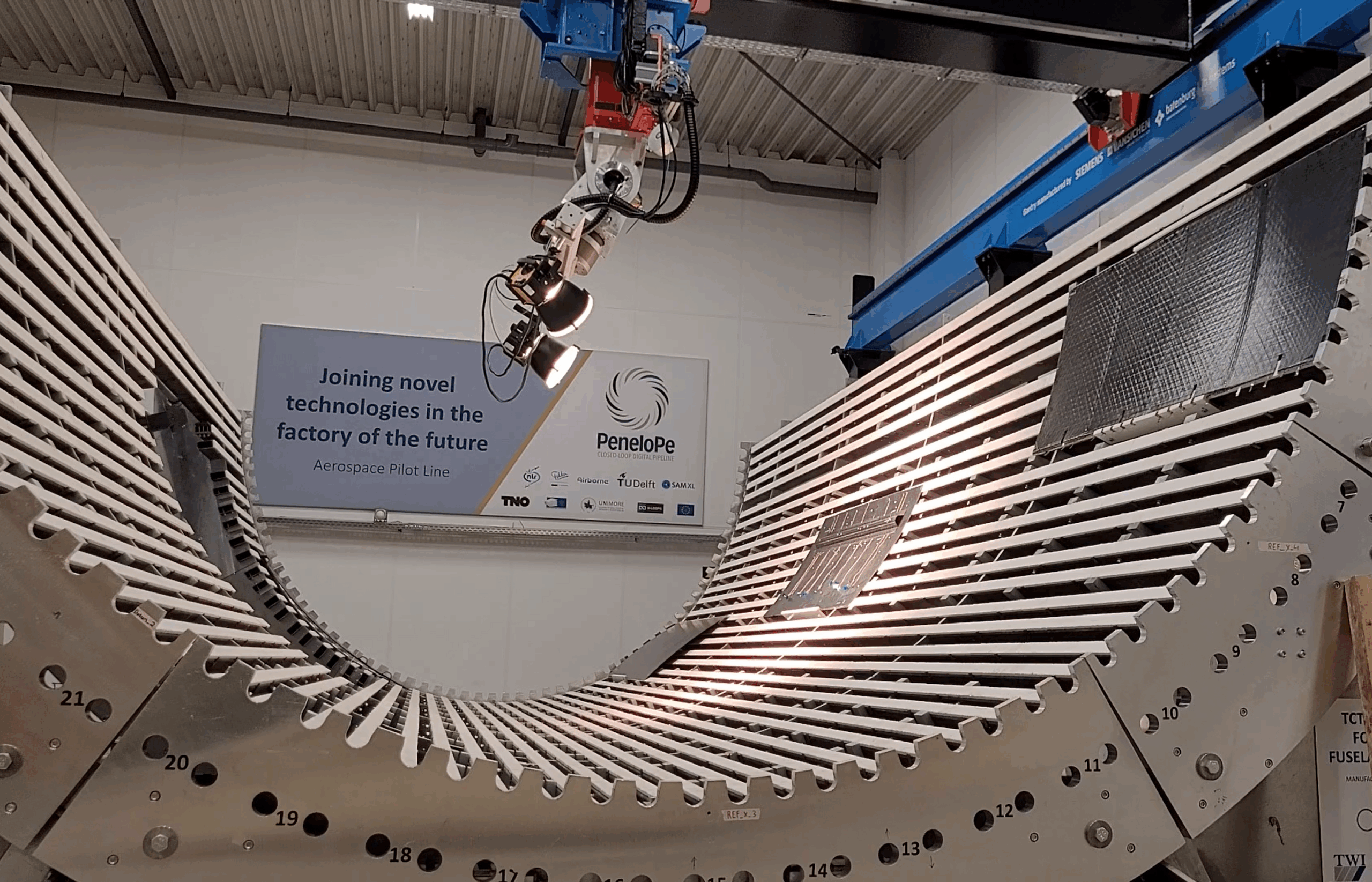

Project partners:

Industry: Politechnico, Photonfirst

Research organisations: NLR, DLR, DNW

This project has received funding from the Clean Sky 2 Joint Undertaking (JU) research and innovation programme under

grant agreement no. 831969