R&D cases

Filter

Explore our R&D cases

NLR is actively involved in various research projects and programmes in the Netherlands, Europe, and globally. As an independent aerospace research institute, we conduct applied research, focusing on a practical approach and innovative solutions. These R&D cases provide an insight into the diverse range of research activities and the projects we have been involved.

24 February 2026

R&D case: Wind tunnel modelling for Europe’s Ariane 6 launch system

The development of the Ariane 6 launcher was geared towards creating a reliable, flexible, and competitive European launch system. NLR played an important role in this endeavour by providing wind tunnel models at various development stages.

24 February 2026

R&D case: An innovative approach to responsive space-based intelligence gathering

Project: REACTS (Responsive European Architecture for Space)

23 January 2026

R&D case: Neutralising hazards and risks for chromated aircraft scrap handling

Project: PANTHER (Painted Metallic Aircraft Scrap: Neutralizing Toxic Hazards and Exposure Risk)

26 November 2025

R&D case: Hydrogen drone research

Project: HYDRA II (Hydrogen Drone Research Aircraft)

21 October 2025

R&D case: Innovative airframe component designs for reducing aircraft noise

Project: INVENTOR (Innovative design of installed airframe components for aircraft noise reduction)

29 September 2025

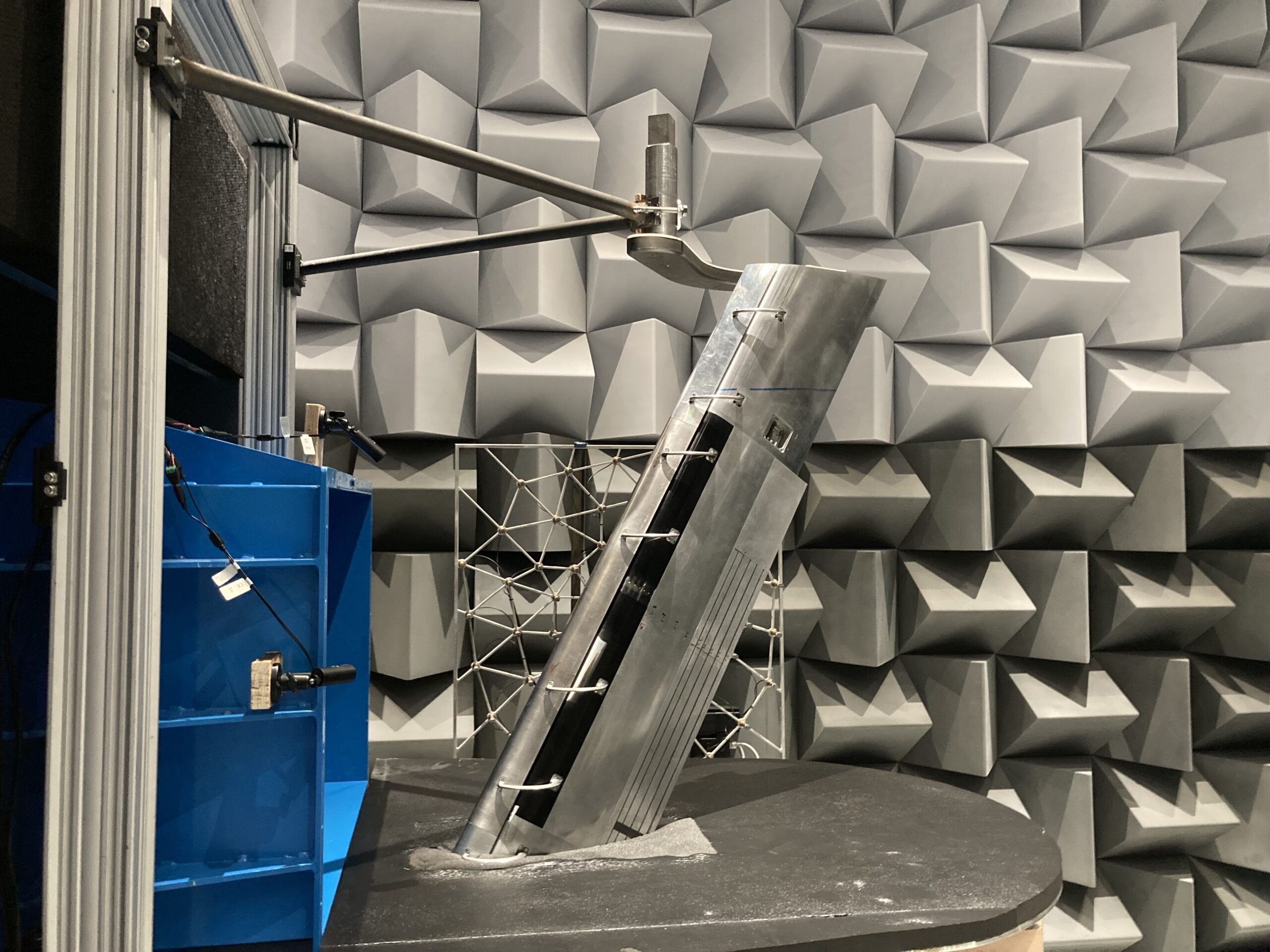

R&D case: Integration and certification of LIG Nex1’s AESA radar using NLR’s Cessna Citation II

Project: FLANS (Flight test LIGNex1 AESA NLR Support)

29 August 2025

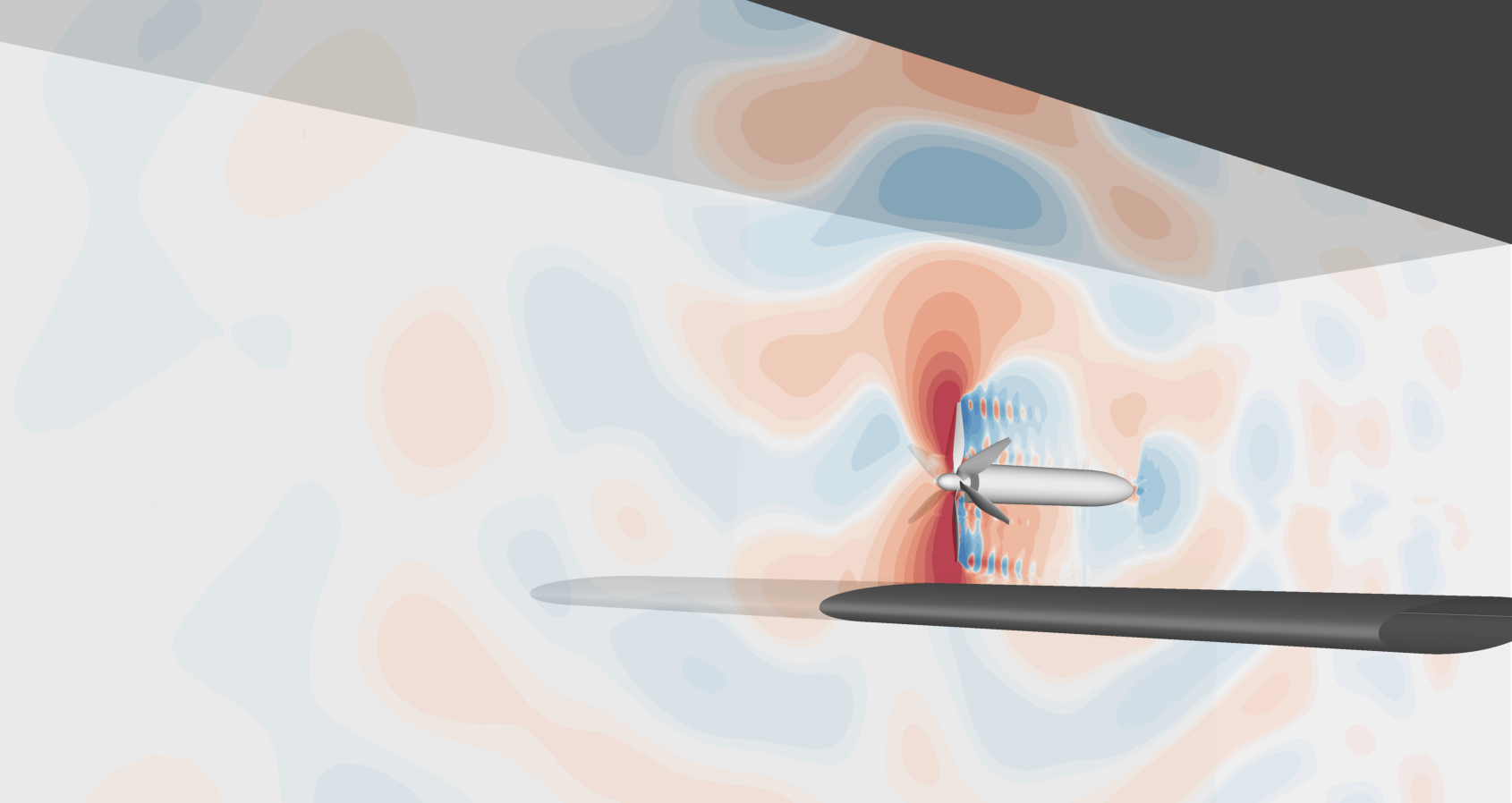

R&D case: Optimising disruptive airframe-propulsion integration concepts

Project: ENODISE (Enabling optimised disruptive airframe-propulsion integration concepts)

Sign up for the NLR newsletter to receive our latest news, recent developments, new insights, reports and whitepapers, as well as our calendar of upcoming trade fairs and events.