Project: HYDRA II (Hydrogen Drone Research Aircraft)

Drones offer an ideal platform for safely testing hydrogen technologies on a smaller scale and at a relatively low cost. In 2019, Royal NLR was the first to fly a drone powered by gaseous hydrogen in Dutch airspace as part of the HYDRA I project. Building on this success, the follow-up project, HYDRA II, marked a Dutch premiere by flying a liquid hydrogen-powered drone in August 2025. This milestone provides additional insights into the research and development of alternative fuels and paves the way for sustainable aviation.

The challenge

As hydrogen offers extended flight duration and distance, beyond what is possible with batteries alone, flying on liquid hydrogen is crucial to achieving the necessary range to be considered a viable alternative fuel in sustainable aviation. Gaining practical experience in enabling and conducting such flights is essential to effectively support its real-world application in drones and its scalability to crewed aircraft.

The solution

The HYDRA II project contributes to the standardisation and certification of hydrogen systems for commercial applications. As part of this effort, handling and operational safety procedures were developed, which can be adopted by other (drone) operators and used by regulatory authorities as a benchmark. This will ultimately facilitate the scalability of these systems to crewed aircraft. Additionally, the findings from the analysis of the electrical architecture and thermal management system required to store hydrogen at -253°C/20K can inform fuel cell and tank manufacturers.

What we did

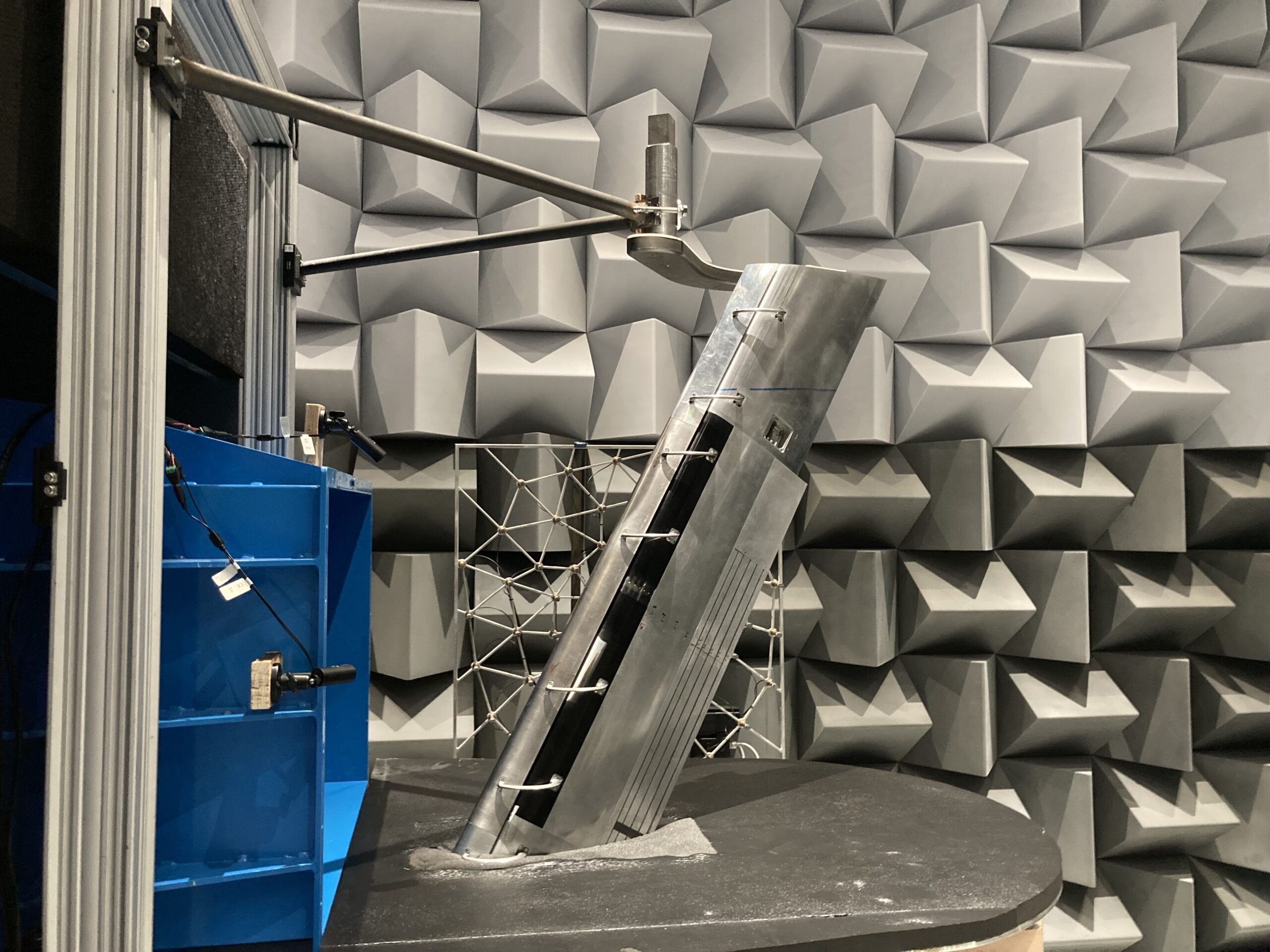

NLR developed the liquid hydrogen (LH2) infrastructure and designed a hydrogen-propulsion conditioning system in preparation of flying the HYDRA II drone on LH2. To achieve this, our initially electrically powered drone was equipped with a powertrain comprising a fuel cell, cryotank, and heat exchanger. Additionally, we conducted safety analyses (EVD, HAZOPs, SORA), test procedures, gained practical experience with these systems, and refined our internal processes, all of which were crucial steps within this project.

Research organisation:

Royal NLR (knowledge development project)

Project timeline:

2020-2025