Embracing the climate crisis more than ever, the global aviation sector has intensified its search for measures that can help decarbonise aviation. As is also shown by Destination 2050, an industry roadmap towards net-zero CO2 in 2050 that was published by the Netherlands Aerospace Centre (NLR) and SEO earlier this year, sustainable aviation fuels (SAF) are seen as a crucially important contribution.

SAF explained

Sustainable aviation fuel (SAF) is aircraft fuel that is produced from renewable resources. SAF is an attractive option for a variety of reasons. As it is chemically almost identical to kerosene, it provides the same large amount of energy per unit mass and can be used in today’s aircraft and filling systems. On top of that, it yields significant lifecycle CO2 savings. Under new European legislation, the lifecycle CO2 emissions of SAF must be at least 65% lower than for fossil-based kerosene. That means that although using SAF still releases the same amount of CO2 into the atmosphere as the combustion of fossil kerosene would, most – if not all – of that CO2 was previously captured from the atmosphere.

There are a variety of production processes for SAF, but there are two main forms: biofuels and synthetic fuels (also known as e-fuels). Biofuels can be made from agricultural or forestry waste or used cooking oil, for example. Even though these are residual flows (i.e. waste, effectively), they can be used as feedstock for fuels. In the case of synthetic fuel, CO2 is removed from the air using special technology. It is subsequently reacted with green hydrogen – produced using electrolysis using renewable electricity and thereby carbon-neutral – to form the hydrocarbons that make up kerosene.

Current usage of SAF is very limited, at less than 1%. Biobased SAF is being produced at the industrial scale already, though. Synthetic fuels are currently only being produced in laboratory settings. As such, commercial use is not envisaged in the next few years.

“Producing enough SAF to fuel the world’s aircraft fleet is still a challenge,” says Bram Peerlings, one of the authors of the study. “First, we need to further develop factories to make SAF, and then build them.” In the Netherlands, SkyNRG and SynKero are working towards that, as are a number of other companies in other countries. “Secondly, such production facilities need ‘feedstock’: the resources required for producing SAF. That can be biomass, or green hydrogen and CO2 – the latter sourced using direct air capture (DAC) or from recycling carbon from point sources.”

Electric or hydrogen-power

The independent study has investigated the availability of feedstocks for SAF in the Netherlands by 2050 and compared it against the projected fuel demand for flights departing the country in that same year. Possible reductions in demand for jetfuel caused by the introduction of alternatively propelled aircraft, such as those powered by electricity or hydrogen have not been taken into account. Even though that could reduce the demand for SAF significantly, it will only affect the demand for energy to a lesser extent.

Advanced feedstocks

For biofuels, the team has only looked at advanced feedstocks. Co-author Elisabeth van der Sman explains: “The sustainability of feedstocks is key for guaranteeing their emissions savings, so we’ve only considered what are known as second-generation feedstocks, such as municipal solid waste, used cooking oil and the agricultural and forestry residues. First-generation feedstocks, which for example compete with food production or are associated with deforestation, were excluded from the start. Similarly, we have only studied pathways for synthetic kerosene that use green hydrogen, produced with renewable energy.”

Findings

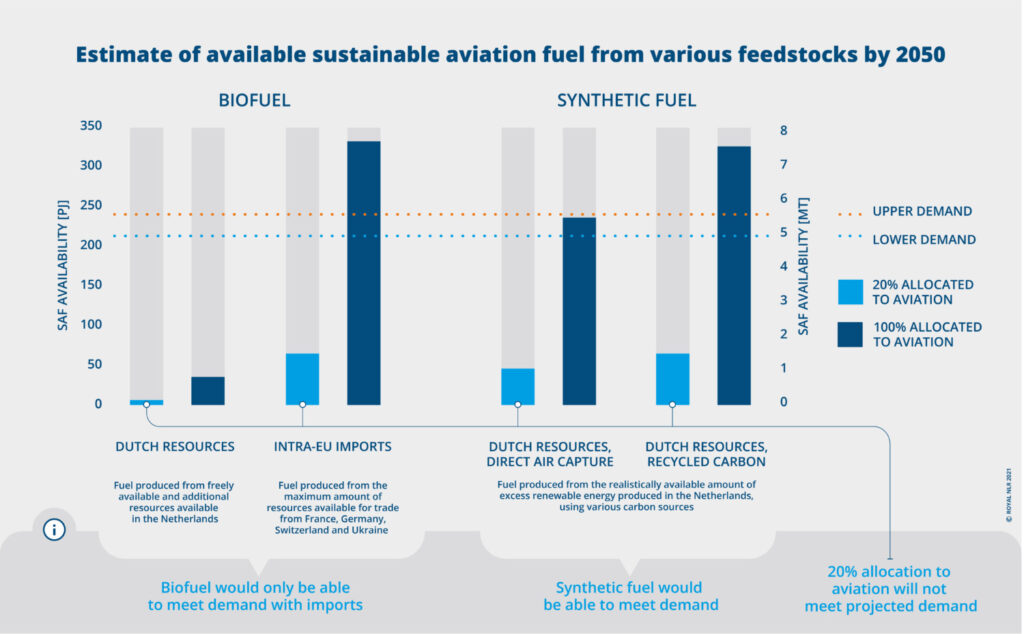

The report’s findings are summarised in the figure below. The dotted orange and blue lines represent the projected energy demand from the aviation sector by 2050, taking account of growth as well as improvements in flight efficiency and the introduction of more fuel-efficient aircraft. The four sets of columns show the amounts of SAF that can be produced from the various groups of feedstocks that are available.

“The figure shows that biofuel feedstocks available in the Netherlands will not be able to meet the demand in 2050,” adds Van der Sman. “If we import feedstocks from other European countries or produce synthetic kerosene from renewable electricity that can be generated in the Netherlands, we would potentially be able to meet the projected demand.”

Uncertainties

These findings, however, come with an important caveat, notes Peerlings. “We currently don’t know how biomass or renewable energy will be shared among sectors and industries, so we have modelled two scenarios. In one scenario, 100% of available feedstocks are allocated to the aviation sector and in the other, we’ve only allocated 20% of available feedstocks to aviation. In that case, none of the four feedstocks and production pathways that we’ve studied are enough to meet projected demand.” The report makes a number of recommendations for further research. “The first recommendation relates to energy demand”, says Peerlings. “As alternative propulsion sources are also being explored for reducing aviation’s carbon footprint, we need to get a more detailed understanding of the demand for a variety of future energy sources. Such a study should consider not only sustainable kerosene but also hydrogen and green electricity used by battery-electric or hydrogen-powered aircraft. Secondly, we should study feedstock demand and allocation across the entire Dutch economy, to help determine what percentage of the feedstocks will be made available to aviation.”

Download The report ‘Feedstocks for sustainable aviation fuels in the Netherlands’

“Thirdly,” adds Van der Sman, “our analysis clearly shows – for feedstocks available in the Netherlands – that synthetic fuels are far more promising than biofuels. In our view, that is an opportunity for the Netherlands to pursue a leading position in producing synthetic SAF – also shown by the High-Level Conference on Synthetic Sustainable Aviation Fuels held in February and KLM’s first passenger flight partly fuelled by synthetic kerosene, conducted the same month. However, that also requires the government to take into account the energy required for SAF production in future energy planning. Our analysis has shown that’s possible, but action is needed to unlock that potential.”