The challenge

Current SmallSat avionics are not suitable for commercial SmallSat missions. The challenge is here to get to a solution with a proper balance between size, versatility, reliability, robustness to the space environment and cost effectiveness. A solution using space qualified parts is too expensive and bulky and a solution based on commercially off the shelf (COTS) components will not offer the reliability and quality assurance customers demand.

The solution

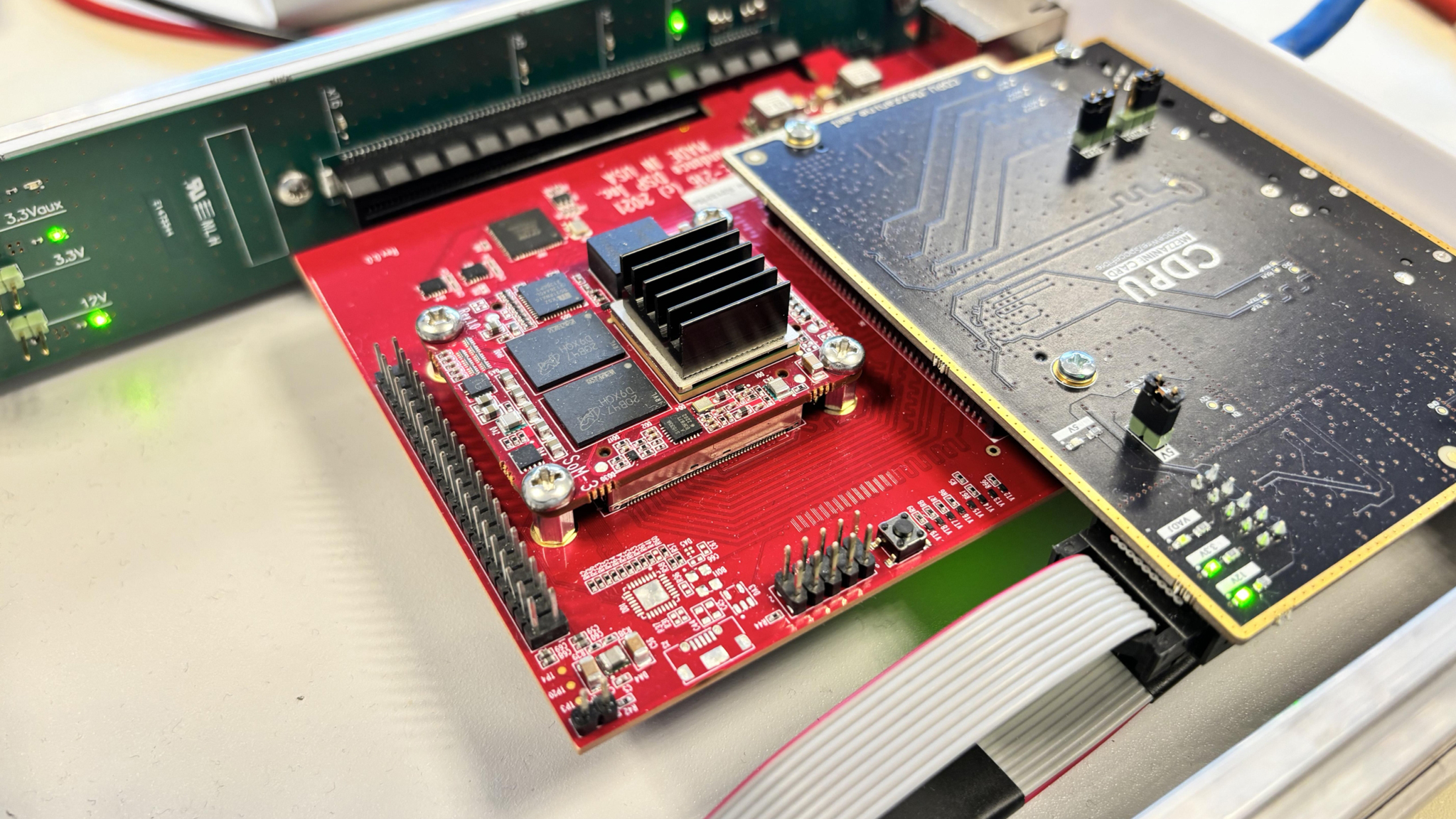

The solution is using radiation tolerant parts at critical places mixed with well characterised COTS components. Proven and effective processes from traditional space are applied to assure the quality and reliability. Versatility is offered by the modular approach using a generic central processing module, an Instrument Specific Module offering the interfaces and hardware functions to the payload and the Platform Specific Module offering the interfaces to the satellite platform including a barrier for failure propagation towards the other satellite systems.

What did we do?

During a one-year Dutch national space innovation programme (SBIR), a proof-of-concept is developed and demonstrated. NLR applied it’s experience on high-reliability space avionics and space standards while our industrial partner Technolution Advance applied their efficient, high-quality and secure development approaches.

This is a strong collaboration combining the best experiences (i.e. expertise from traditional space processes and agile hardware development techniques) to develop an attractive product. The project contained two focus areas;

>

- a technology development part aiming for optimised architecture and key parts selections.

- a business case refinement part with extensive consultation with potential stakeholders including ESA.

In addition to the finalised project several R&D activities are being performed on specific product details. One example is the R&D on a robust and secure RISC-V processor for harsh environments under an EU Horizon KDT-JU (Key Digital Technologies Joint Undertaking) project.

Project partners:

Industry (NL):

Research organisations:

This project has received funding from the Clean Sky 2 Joint Undertaking (JU) research and innovation programme under

grant agreement No xxxxxxx.