ARTEX: Augmented Reality for Technical Exploitation in C-IED Operations

The challenge

Improvised Explosive Devices (IEDs) are a day-to-day reality in conflicts and are regarded by the armed forces as tactical weapons with a strategic effect. IEDs inflict fatal or serious injury and damage to personnel and equipment, limit the freedom of movement and mobility of military units, and pose a serious threat to the success of and support for missions.

In order to provide insight into information about IEDs and the IED network, information from IED components or remnants, documents, electronic data carriers and detainees is secured, gathered, analysed and processed. This multi-stage process is called Technical Exploitation (TE). Communication between operational TE experts, gathering information and sharing knowledge and resources are among the numerous urgent challenges in this process

The solution

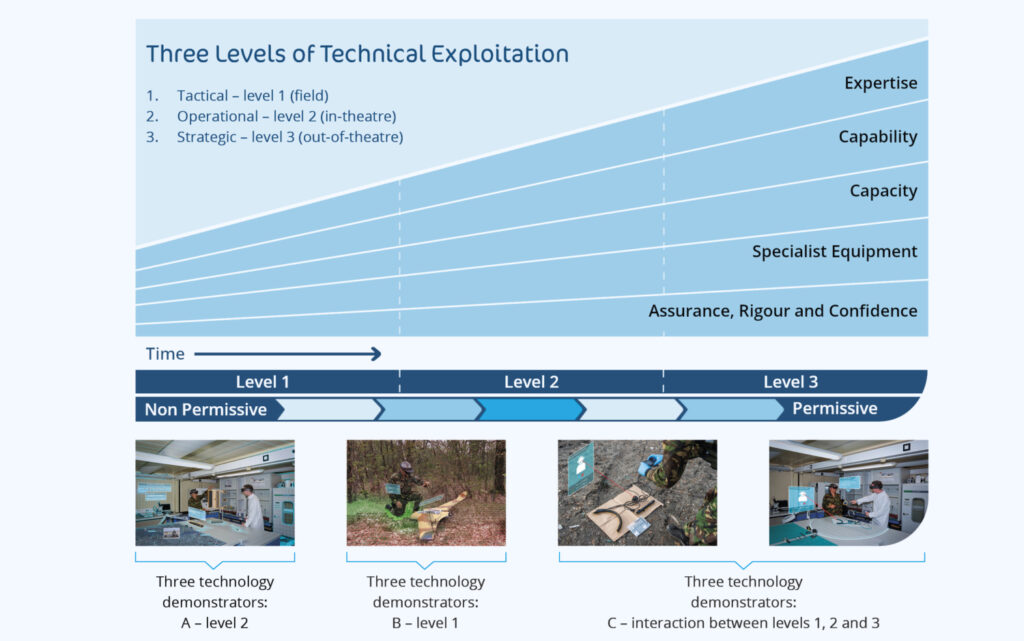

The goal of this project is to consider the way Augmented Reality (AR) can improve and speed up the TE process in Counter-IED operations, while decreasing operational risks. To attain this goal, three technology demonstrators (TRL 6-7) are developed, aiming to rise to the aforementioned challenges.

What did we do?

The first demonstrator aims to support the TE level 1 specialists, who are responsible for the identification and collection of objects of interest in non-permissive environments. The ARTEX demonstrator supports them, amongst others, by automatically creating a map of the building that is being exploited and the ability to digitally record and collect information about the encountered objects.

This enhances the shared situational (and spatial) awareness, which could enhance the communication between experts. The second demonstrator focusses on the TE level 2 specialists, who work in an in-theatre laboratory to exploit the objects their colleagues at level 1 have collected earlier. Different cases can be compared in a situational AR overview, identifying matching components. The third demonstrator focusses on the (real-time) interaction between TE level 1 and 2 experts.

Project partners:

Defence Science en Technologie (S&T)

Defence Equipment Organisation (DMO)

Defence Expertise Centre Counter-IED (DEC-CIED)

Start : January 2020

Duration : 2,5 years