Mini multi parallel micro pump development

The challenge

Development, production and launch costs for CubeSats are very low compared to conventional satellites. This has sparked interests from industry to develop their own CubeSats. The drive for volume and mass optimisation from the industry has led to miniaturisation of electronics in CubeSats. To keep costs down, commercially available electronics (COTS) are used which are very cost effective but have a small operational temperature range. The relatively high power density of CubeSats means that more power is being transferred into heat in the same volume, causing a faster warmup of components. The thermal problems are aggravated by the introduction of propulsion modules for CubeSats which themselves produce a large amount of heat. Without adequate heat removal the CubeSat components can quickly overheat.

The solution

Conventional methods like heat pipes to remove this heat are no longer suitable, and mechanically pumped loops are a feasible solution to remove this heat as they are more efficient. However, these loops are usually expensive and need much smaller mass flows compared to the larger satellites. To create a smaller mechanically pumped loop, a smaller, flexible pump is needed which is the goal of the MPMP. A consortium of Demcon Kryoz, ISISpace and Royal NLR, with support of the European Space Agency (ESA) aims to develop the MPMP for use in small satellites.

What did we do?

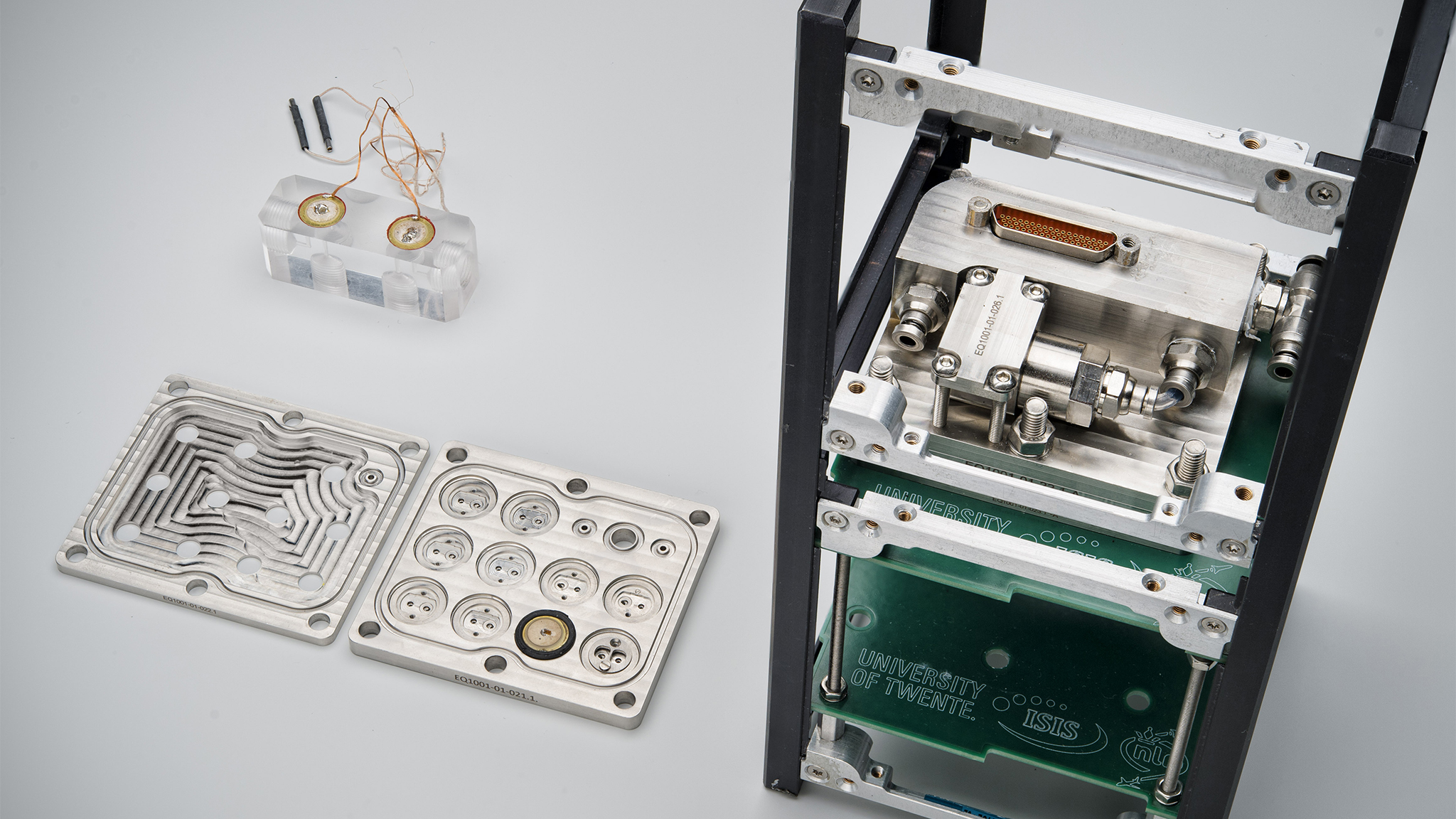

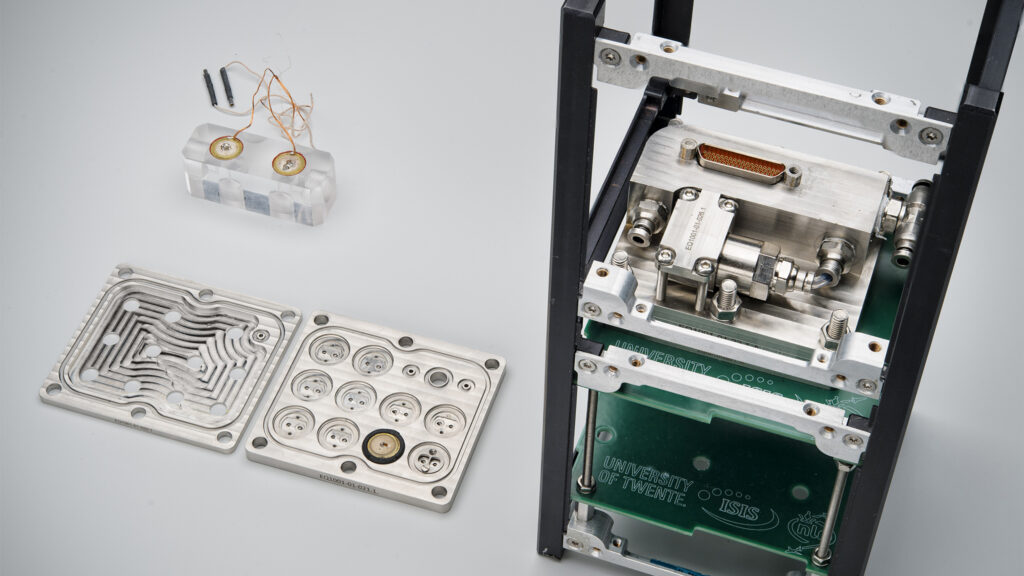

The Multi Parallel Micro Pump consists of a stack of several micro pumps, which consists each of a piezo membrane and a valve to direct the flow. The prime functionality lies in the flexibility the current solution offers: if a higher flow is needed, more pumps can be added to be able to deliver that flow; which also helps in the robustness. For typical space applications expensive pumps are used, and due to redundancy reasons, added with a second back up. With for instance 20 micropumps placed in one stack,

the loss of one single pump will not result in loss of functionality of the loop, but will lower the flow with 5%. We currently have a full scale MPMP prototype which has demonstrated a mass flow of 500 mg/s which is sufficient to transport at least 20 watts of heat. The consortium aims to improve upon the design to transport at least 100 watts of heat away from a heat source, such as a CubeSat propulsion module, to a heat sink elsewhere in the satellite.

Project partners:

Industry (EU) : Demcon Kryoz, ISISpace

Research organisations : Royal NLR, ESA

Start : 2021

Duration : 2 years