Formulation of training and simulation vision including a roadmap for implementation

The challenge

Many nations are facing the question of what to do with their end-of-life simulators and how to ensure their replacements will be more (cost-) effective, efficient, and future-ready. The Swiss Armed Forces are investigating possible options for developing a new portfolio of training simulators. The options should fit the envisaged Swiss Armed Forces’ future training needs and budget for 2030 and beyond.

The solution

The project provided guidance for a high-level outline of options for a future training simulator portfolio with a broad outline of an implementation roadmap and plan for the Swiss Armed Forces. The key to the success of the selected option is to formulate a modern vision on training and simulation.

What did we do?

The project provided guidance for a high-level outline of options for a future training simulator portfolio with a broad outline of an implementation roadmap and plan for the Swiss Armed Forces. The key to the success of the selected option is to formulate a modern vision on training and simulation. Three different options were put together for realising the training demands and constraints.

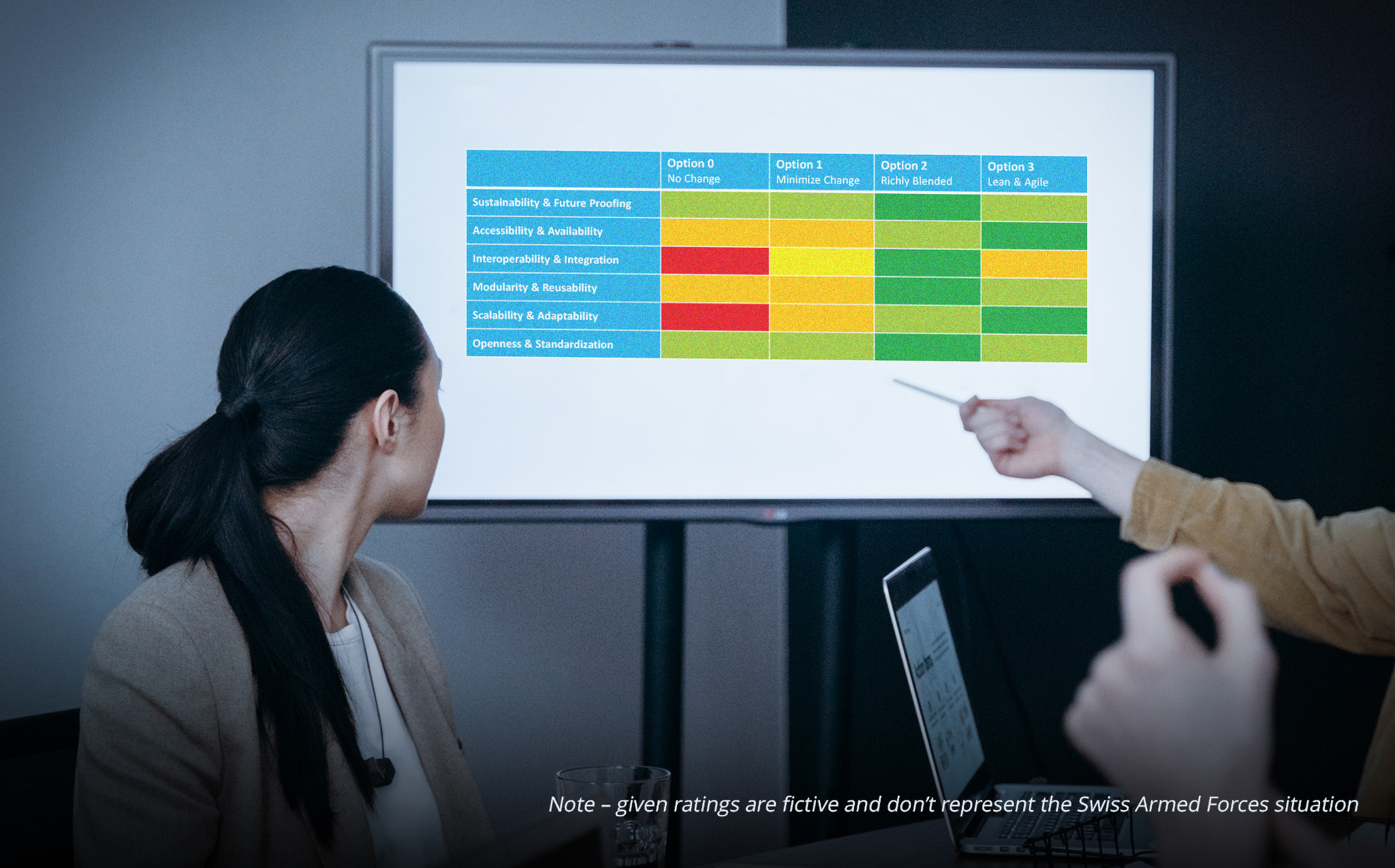

One option aimed for simulator replacement with limited change (‘Minimise Change’), a second aimed to take advantage of the large variety of envisaged training media, including VR, AR, MR and PC-based simulation (‘Richly Blended’). A third option aimed to maximise PC-based simulation (‘Lean & Agile’). All options require a considerable level of integrated simulation infrastructure. The three options were compared in terms of initial investments, cost reduction and training value against the current situation (‘business as usual’) as the baseline.

A roadmap was outlined towards implementation of the selected option.

Project partners:

Industry (EU): Armasuisse, Swiss Armed Forces

Hulleman Expertise

Research organisation: Royal NLR

Start: September 2017

Duration: 1.5 years