24 February 2025

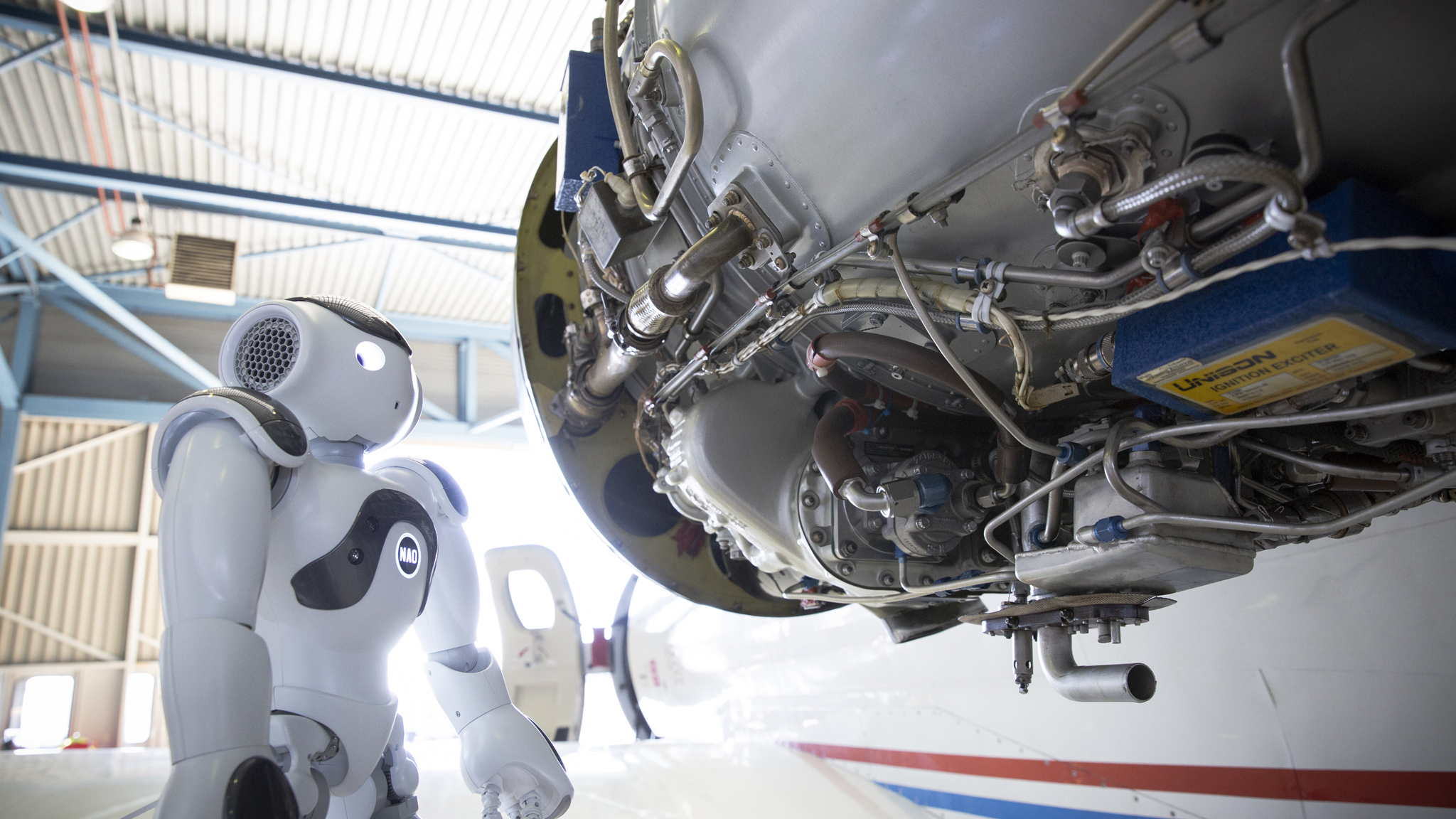

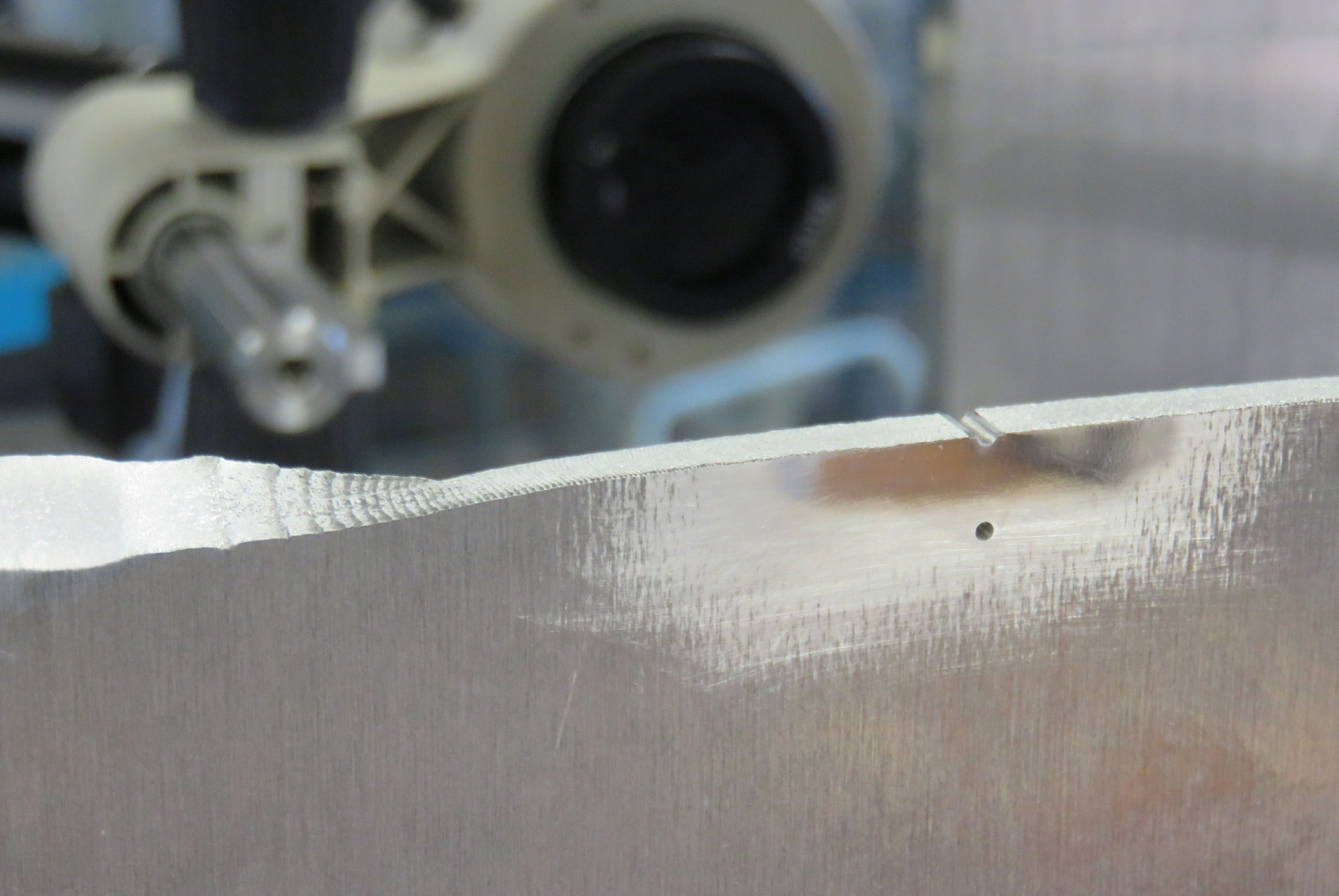

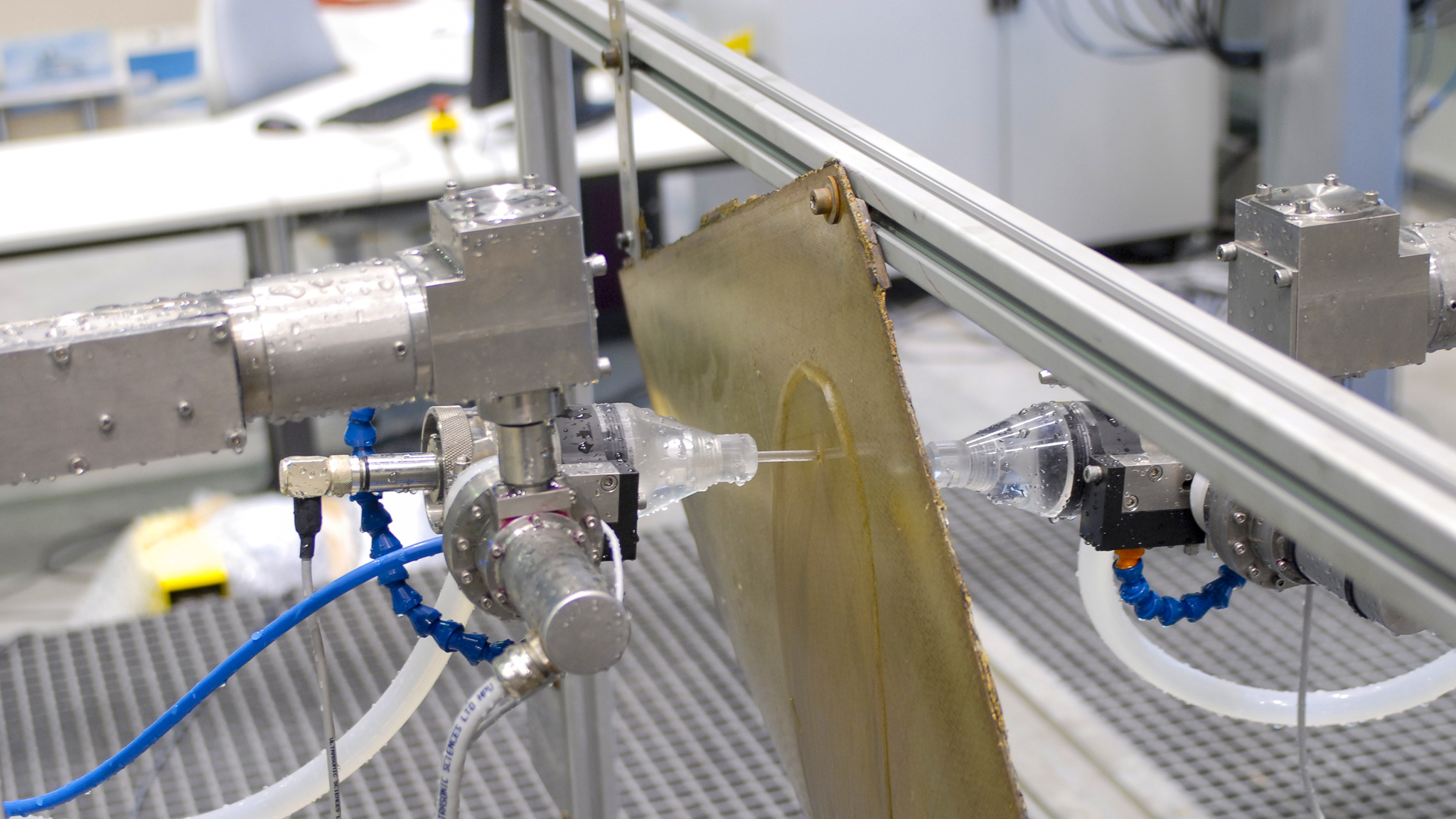

Structural integrity

NLRs structural integrity capability helps organisations optimise the operation of their (military) aircraft. We support the optimisation of usage and maintenance, aiming to maximise operational readiness while minimising costs and maintaining safety standards. Our expertise can also help extend component life and reduce maintenance costs.