Avy, a pioneer in autonomous sustainable drone solutions, has entered into a strategic collaboration with Royal Netherlands Aerospace Centre (NLR), a leading authority in aerospace research and innovation. As part of this partnership, NLR has acquired an Avy latest generation Aera Unmanned Aerial Vehicle (UAV) for testing and operational evaluation. Additionally, NLR will leverage its expertise to help Avy audit and enhance its operational capabilities.

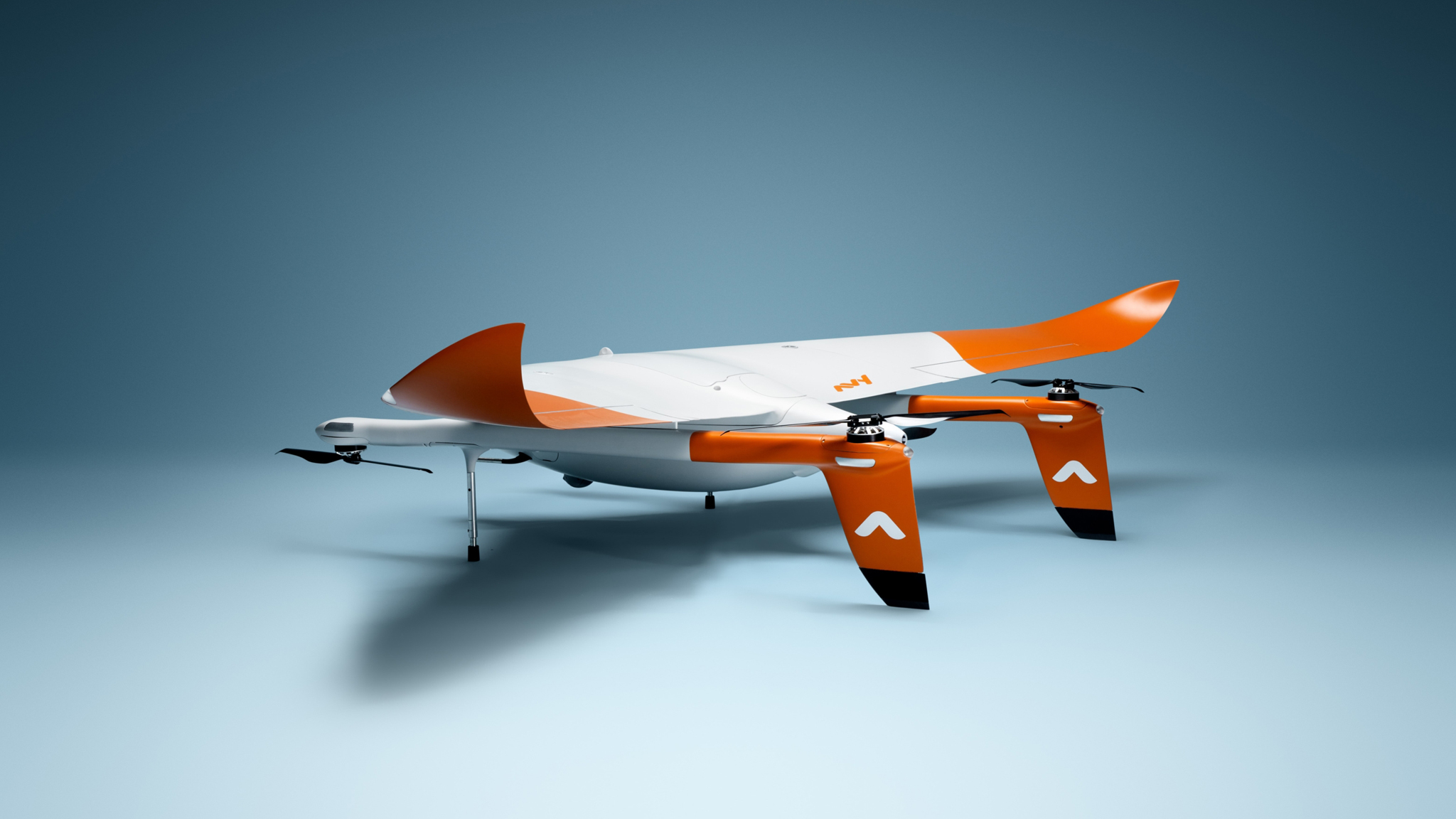

The Avy Aera, recognized for its emission-free and autonomous flight capabilities (Beyond Visual Line of Sight), will be integrated into NLR’s research programs. These programs focus on testing innovative aerospace applications, including emergency response, monitoring and urgent logistics. The Aera’s capabilities, such as long-range autonomous flight up to 100km, and advanced safety features, make it an ideal fit for NLR’s pioneering initiatives.

Simultaneously, NLR’s collaboration with Avy extends beyond product deployment. As part of its commitment to develop excellence in aerospace practices, NLR will conduct a comprehensive audit of Avy’s operations. This process aims to ensure Avy’s workflows align with industry-leading standards and guarantee optimal performance across product design, manufacturing, deployment, and regulatory compliance.

“Partnering with NLR is a significant milestone for Avy,” states Benjamin van der Hilst, CEO of Avy. “Their expertise in aerospace innovation and rigorous operational auditing will accelerate our mission to revolutionize UAV solutions while maintaining the highest standards of quality and sustainability.”

Michel Peters, CEO of Royal NLR, fully agrees: “It is a core objective of NLR to support the Dutch aviation industry in establishing a strong position in the UAM supply chain. Therefore, we’re very pleased to test the potential of this sustainable and innovative designed Dutch drone in various applications while supporting Avy in enhancing their operational frameworks.”