Improving aerodynamics to reduce noise pollution

After completing her studies in Mechanical Engineering at the University of Twente, Kylie Knepper immediately started working at NLR, in the Vertical Flight and Aeroacoustics department. This was over ten years ago, and she still learns something new every day. As an R&D Engineer in Aeroacoustics, Kylie is right at the forefront of important innovations in aviation. Aerodynamics and acoustics are closely linked; improving aerodynamics is an effective way to reduce noise from aircraft. “To limit the noise of an aircraft as much as possible, we look at how to make the airflow around the aircraft as efficient as possible”, Kylie says. Improvements to aircraft, such as enhancing aerodynamics and reducing weight, contribute to both more sustainable and economically efficient aviation. “For example, consuming less fuel will contribute to reducing both the cost and environmental impact of flights.”

Wind tunnel testing: an important milestone

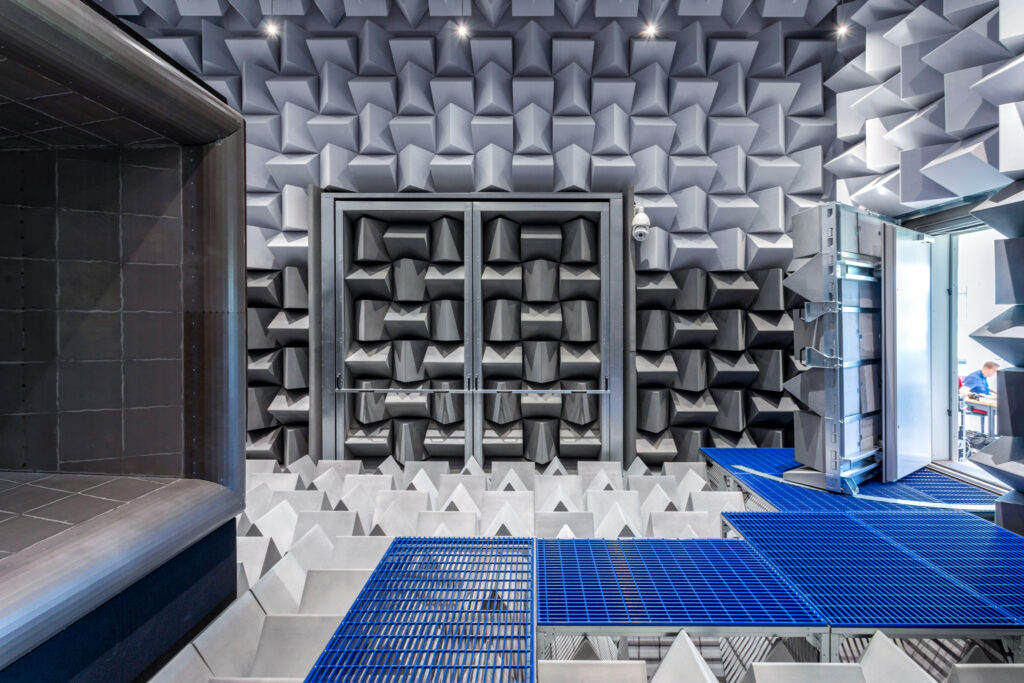

Kylie has taken on a project leadership role for wind tunnel tests in recent years, in addition to her work as an engineer. The tunnel is used to simulate real-world air conditions. These tests are crucial for the development and certification of aviation innovations.

“We test a wide range of things, from new propulsion technologies, such as propellers on an aircraft and new engines, to efficient wing concepts”, Kylie explains. Her tasks are diverse and include conducting conversations with clients, writing project proposals, and leading projects. In addition, she performs technical work herself. “The mix is what makes it so interesting”, she notes. The clients for wind tunnel tests vary greatly as well, and range from small and large companies to governments and defence organisations. Wind tunnel tests at NLR are also regularly used in European research projects.

From theory to practice

Research often begins with a theoretical concept. Wind tunnel tests typically require months or even years of preparation. “We map out the test programme and create the model. We investigate, among other things, the scale on which we will make the wind tunnel model and examine what equipment and test conditions are needed to obtain the right measurement results. It’s a complex set of factors we need to take into account.”

Once everything looks good on paper, the first tests can be carried out in the wind tunnel. “This usually only takes a few weeks, much shorter than the preparation time”, Kylie laughs. It is, however, a busy time for her as project coordinator. “Something unexpected always happens during testing. Then we have to assess if and how we’re going to deviate from the test programme, in close consultation with the client.” The next step is to put the results into practice. Kylie: “For sixty years, there has been speculation in our field that wind tunnel tests will become a thing of the past thanks to digital modelling and simulation. Yet I am convinced that they will remain relevant. After all, wind tunnel tests provide a vital link between theory and practice.”

The linchpin

She is responsible for coordinating wind tunnel tests, acting as a linchpin between colleagues and clients, and ensuring a seamless process. Kylie’s team-oriented approach extends beyond her work. In her free time, she enjoys playing korfball and competes in tournaments on weekends. She is also part of a harp ensemble. “I was brought up with music by my parents, and I still love practicing. Every two weeks, I take my harp to Hengelo for rehearsals.”

“Wind tunnel tests provide a vital link between theory and practice.”

No two days are the same

While for some, it can be overwhelming to manage complex processes and multiple stakeholders, Kylie thrives in these situations. “Steering large and complex processes in the right direction, that’s what really gives me energy. I draw on my own knowledge, but I also love bringing together the expertise and skills of colleagues and partners.” She enjoys the multidisciplinary aspect of her work. “It’s a dynamic environment where you can learn something new every day.”

Steady growth

Kylie makes well-considered decisions and always takes all sides of an issue into consideration. Looking back on her career so far, she says: “I don’t make big jumps or drastic changes in my career, it’s steady progress.” She is proud of the steps she has taken. “It was a special moment when, after a couple of years of working with the team, I was given the opportunity to lead my first major project. We were doing a wind tunnel test for the development of CROR (Counter Rotating Open Rotor) engines.”

Developing new measurement technology

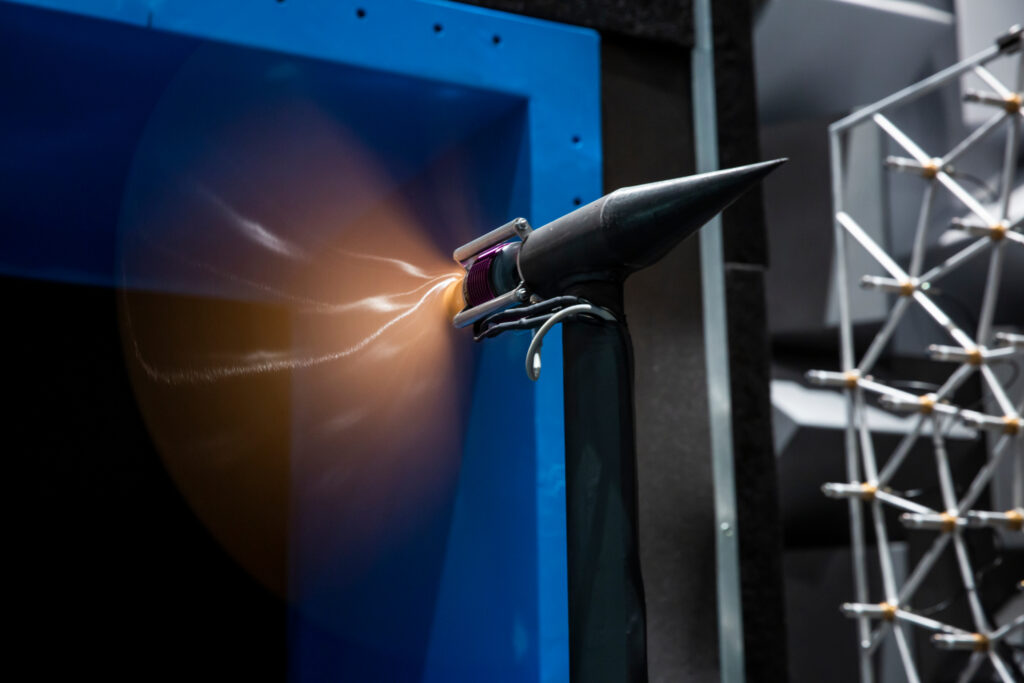

One of the largest projects Kylie has worked on recently is the showcase that concluded the strategic programme ‘Development of Aerospace Vehicles’ within NLR. The teams involved worked together on the outermost section of a passenger aircraft’s wing. Kylie and her team developed a measurement technique to measure the deformation of aircraft components – such as a propeller or a wing – and the airflow around them.

Deformation of a propeller or wing in the air may seem alarming, but it’s not at all. To make aircraft quieter and more efficient, propeller blades and (parts of) wings are increasingly made of composite materials instead of metal. These materials are lighter and make aircraft more fuel-efficient. However, composites are also more flexible than their metal counterparts. “This allows us to further optimise the wings and propellers and ensure the most efficient flight possible. But it is essential to monitor the flexibility properly, and study its impact on airflow”, Kylie explains. For instance, researchers can determine whether an aircraft remains airborne by calculating its lift. Additionally, they can examine the impact on noise levels. Until now, it was only possible to measure the flexibility of a material and airflow separately. Understanding how these factors interact will be crucial going forward.

Short-term and long-term solutions towards more sustainable aviation

Kylie’s ultimate goal is to help achieve more efficient, quieter, and more sustainable aviation. It’s not just about making big changes and radical transformations. “I expect that we will mainly focus on conventional aircraft with relatively small improvements to meet the sustainability targets for 2035. “Using Sustainable Aviation Fuels (SAF), for example, can help reduce aircraft emissions without requiring significant modifications to the propulsion system.”

Looking ahead to 2050, with the aim of achieving completely climate-neutral aviation, entirely new concepts and geometries will emerge on the market, Kylie expects. “Think of fully electric aircraft or other types of aircraft, such as the blended wing body. This type of aircraft has a triangular design. It offers opportunities to make aviation more efficient and sustainable, but there is still much to be researched. For example, how can we efficiently transport people and goods in an aircraft with this new shape? These are questions that our industry will need to address in the coming years.”

Promising developments

There are also other promising developments. Take distributed propulsion, for example. An aircraft would have multiple smaller propellers distributed along the wings, rather than a single large one. Additionally, new engines are being developed, such as the Open Rotor architecture. “Both developments improve the efficiency of aircraft, but they also have drawbacks. For instance, the engines in open rotor designs are not shielded, making them more vulnerable and noisier.” It’s all about striking the right balance to improve aircraft efficiency, make aviation more sustainable, and minimise noise disturbance.

Looking ahead

In the coming period, Kylie will be working towards leading a major, multidisciplinary European project. “Sometimes, the EU poses specific questions or problems, making it relatively straightforward to submit a research proposal. At other times, it’s about broader opportunities for improvement, where we have a lot of freedom to determine our own approach and project scope. In projects like this, it is not just about technical expertise, but also about understanding the context and significance of the research and its impact on European citizens.” Ultimately, one or more parties will be selected from all submitted proposals to work on the project. “It’s a challenging task, but really cool to do.”