Non-destructive inspection (NDI) plays a critical role in ensuring the integrity and reliability of complex systems and components. Our team of scientists and specialists, equipped with novel state-of-the-art facilities, is dedicated to develop and employ tailored inspection methodologies that meet the needs of our clients. We provide assistance to airlines, air forces and aircraft component manufacturers, providing services that span from fundamental research to the qualification of NDI-methods. Our expertise contains a wide variety of NDI-techniques including (laser) ultrasonic testing (UT), eddy current testing (ECT), infrared thermography (IRT), and laser shearography (ST). An overview of our capabilities is displayed in the ‘Non-destructive inspection’ flyer.

NLR can support you with:

- R&D studies (EU and Defence Programs)

- Modelling and simulation of NDI-methods

- Experimental development and evaluation of new NDI-techniques

- Overcoming certification challenges

- Integration of NDI-methods in Maintenance Repair and Overhaul (MRO) processes

- Development of Digital Twins and AI tools

- NDI of composite, metals and fibre-metal laminates (FML) materials

Relevant links

R&D cases

06 June 2025

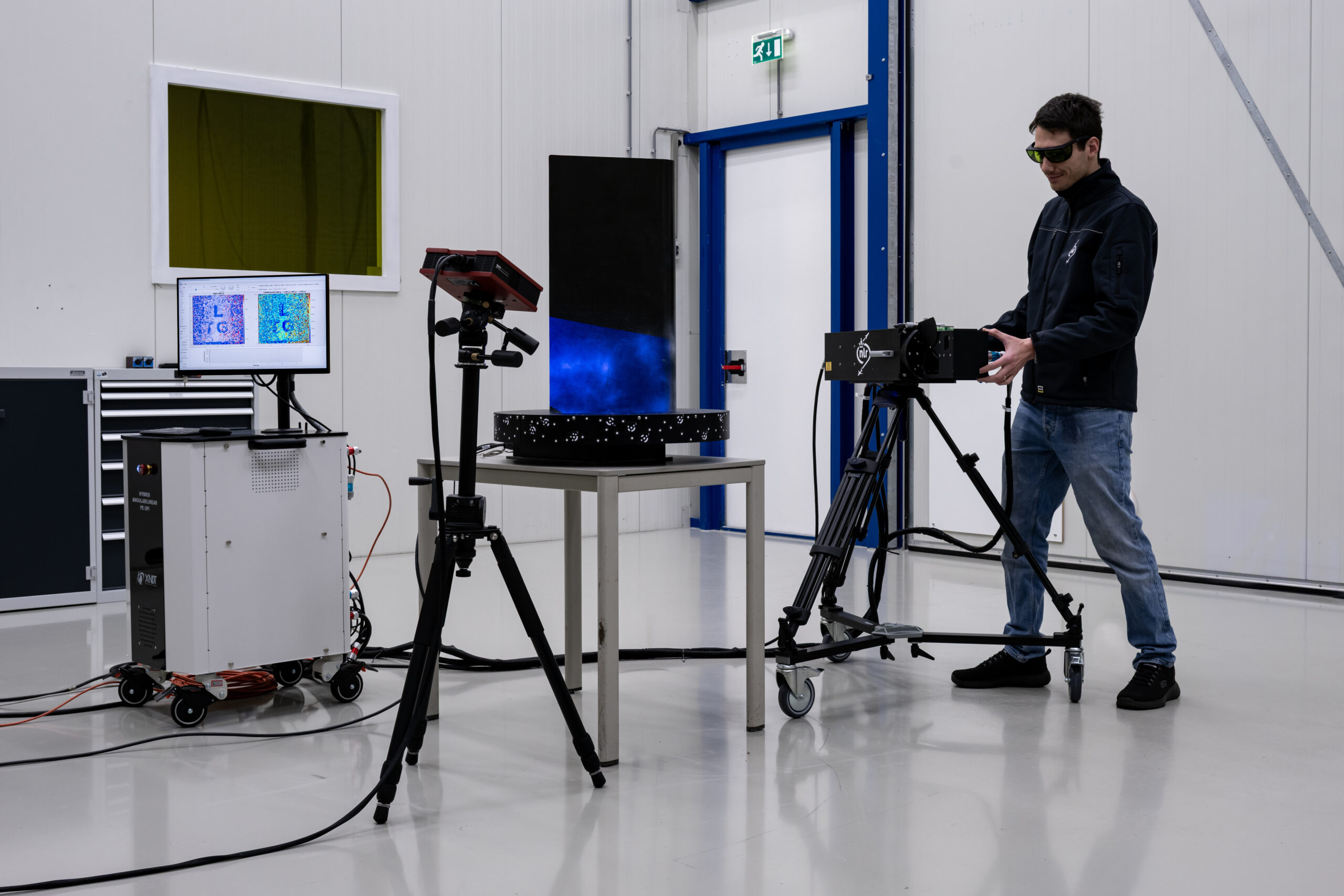

R&D case: Laser ultrasonic inspection of complex-shaped composites

The manufacturing of complex-shaped composites is becoming increasingly common, driving up demand for fast automated quality control. Laser ultrasonic testing can be a viable technique to achieve this, as it is fast and contactless. However, it requires the inspected part to be perpendicular to the laser beam, posing a challenge for the positioning of the laser or part. Combining laser ultrasonics with optical 3D scanning can overcome this challenge and realise a fast automated quality assurance system for composite manufacturing.

28 May 2025

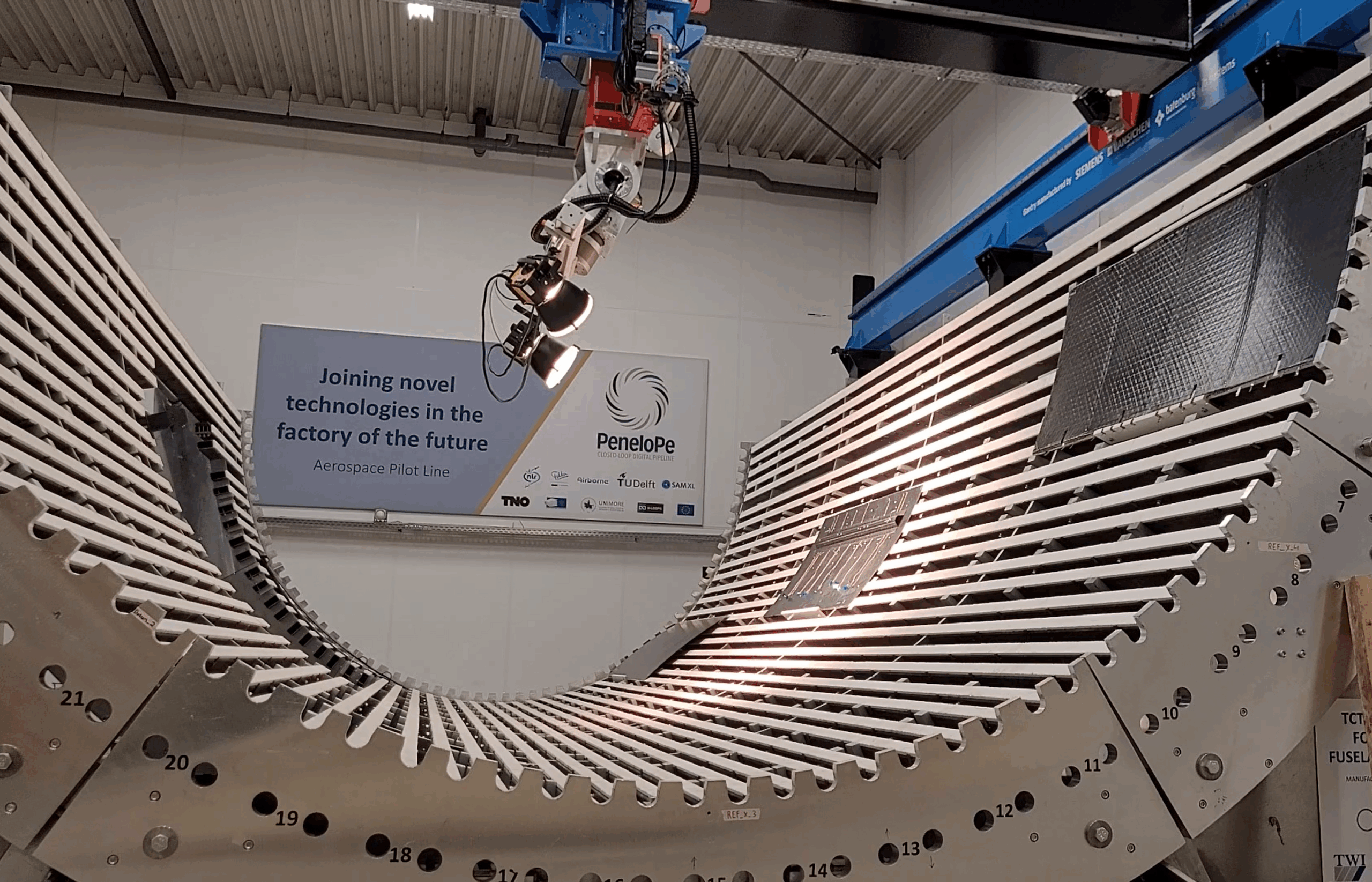

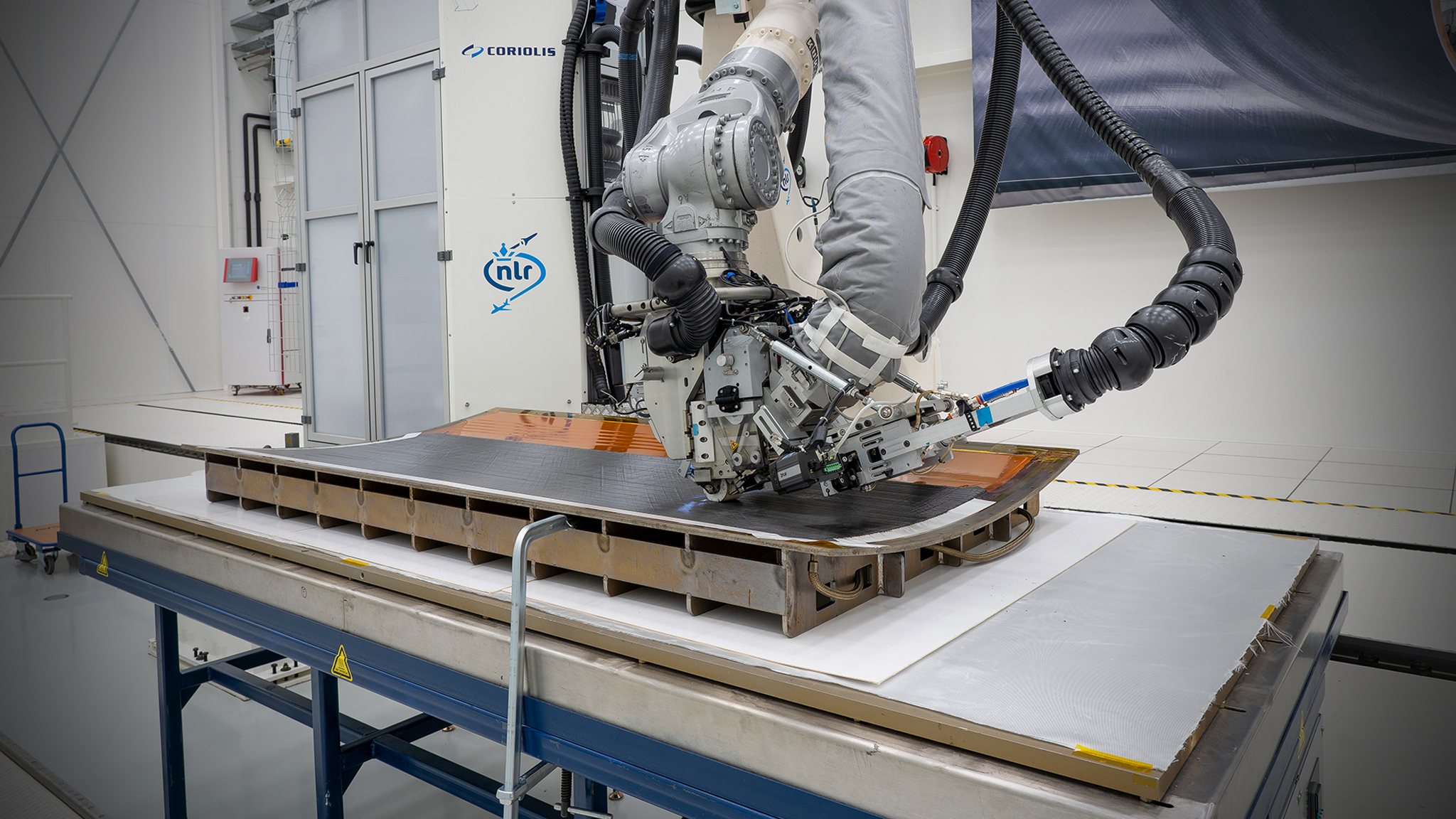

R&D case: Fast non-destructive testing of large composite aircraft structures

Project: PENELOPE (Closed-loop digital pipeline for a flexible and modular manufacturing of large components)

02 October 2024

R&D case: SUSTAINair

SUSTAINability increase of lightweight, multifunctional and intelligent airframe and engine parts

23 February 2023

R&D case: Automated Inspection and Repair of Turbine Blades (AIRTuB)

Offshore wind energy plays a major role in the transition to green energy. The wind turbine blades require periodic inspection. The inspection and repairs are carried out by specialists who descend along the blade on a cable. This is very labour-intensive and an even greater challenge offshore. The AIRTuB consortium developed systems that are mounted on a drone and that can automatically inspect the wind turbine blade and carry out repairs if necessary. Regular inspection allows repairs to be planned in a windless period which prevents loss of production.