To enable safe airspace integration of unmanned aircraft, a Detect And Avoid (DAA) system is required to evade other (manned) aircraft. One solution is to use a Cooperative Traffic Sensor based on transponder signals. Such a sensor is not yet available with a small form factor suitable for unmanned aircraft. Within the Airborne Data Collection on Resilient System Architectures (ADACORSA) project, such a sensor will be developed and tested in cooperation with the partners.

The challenge

The main challenges of the project are:

- The form factor and power requirements of current DAA systems are not suitable for small and mid-sized unmanned aircraft.

- Due to frequency saturation of the manned aircraft transponder frequencies, drones cannot be equipped with ADS-B transponders.

- Manned aircraft with both Mode-S and ADS-B transponders need to be detected.

The solution

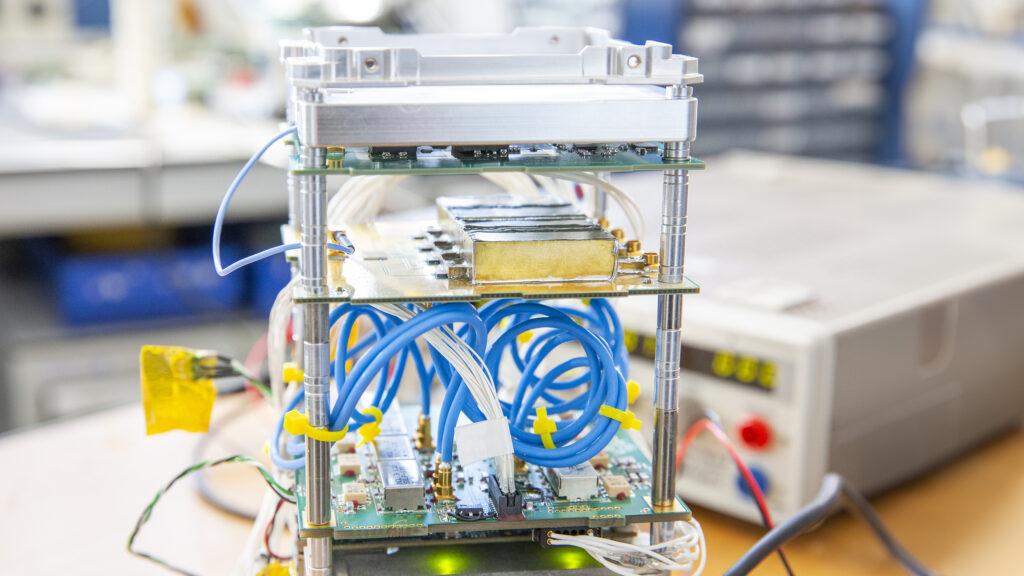

- Miniaturisation of the DAA system suitable to be integrated onboard of small and mid-sized unmanned aircraft

- Sensor suite advancement to include a direction finder to measure the azimuth such that the relative position to the intruders is known

- Information from ADS-B (manned intruder aircraft) will be used to further increase detection of current airspace users

What did we do?

NLR develops a Direction Finder for the Cooperative Traffic Sensor (CTS) and integrates this with a Mode-S interrogator, developed by project partner Celestia Technology Group. The DAA system uses algorithms developed by NLR for semi-automatic avoidance of other aircraft. These algorithms feature both Remain Well Clear (RWC) and Collision Avoidance (CA) functionalities.

The RWC functionality takes into account the rules-of-the-air to calculate a new route for the unmanned aircraft. The calculation is performed onboard to be independent of a data link and allows a fully autonomous system in the future. The DAA system will be integrated and flight tested in the DAA Flying Testbed at the NLR Drone Flight Test Centre. Finally, the developed system will be demonstrated in a logistic support use case

Project partners:

Industry (NL): Anywi, Celestia Technology Group, Embraer, ESC Aerospace, ISEP, etc.

Research organisations: Royal NLR, TUDelft

ADACORSA has received funding from the ECSEL Joint Undertaking (JU) under grant agreement No 876019. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and Germany, Netherlands, Austria, France, Sweden, Cyprus, Greece, Lithuania, Portugal, Italy, Finland and Turkey.

This project is co-financed from the Allowance for Top Consortia for Knowledge and Innovation (TKl’s) by the Ministry of Economic Affairs and Climate Policy.