SCALAiR is part of Clean Sky2 Large Passenger Aircraft, and aims to validate scaled flight testing as a viable means for de-risking disruptive aircraft technologies and aircraft configurations to a high technology readiness level. The NLR activities involve ‘Test Aircraft Preparation and Qualification’ acceptance.

The challenge

The goal is to develop a highly representative scaled aircraft of an actual aircraft, equipped with very accurate flight test instrumentation to perform measurements during the tests. This will introduce a very cost-effective approach to developing radical new aircraft, as needed for more sustainable aviation.

The solution

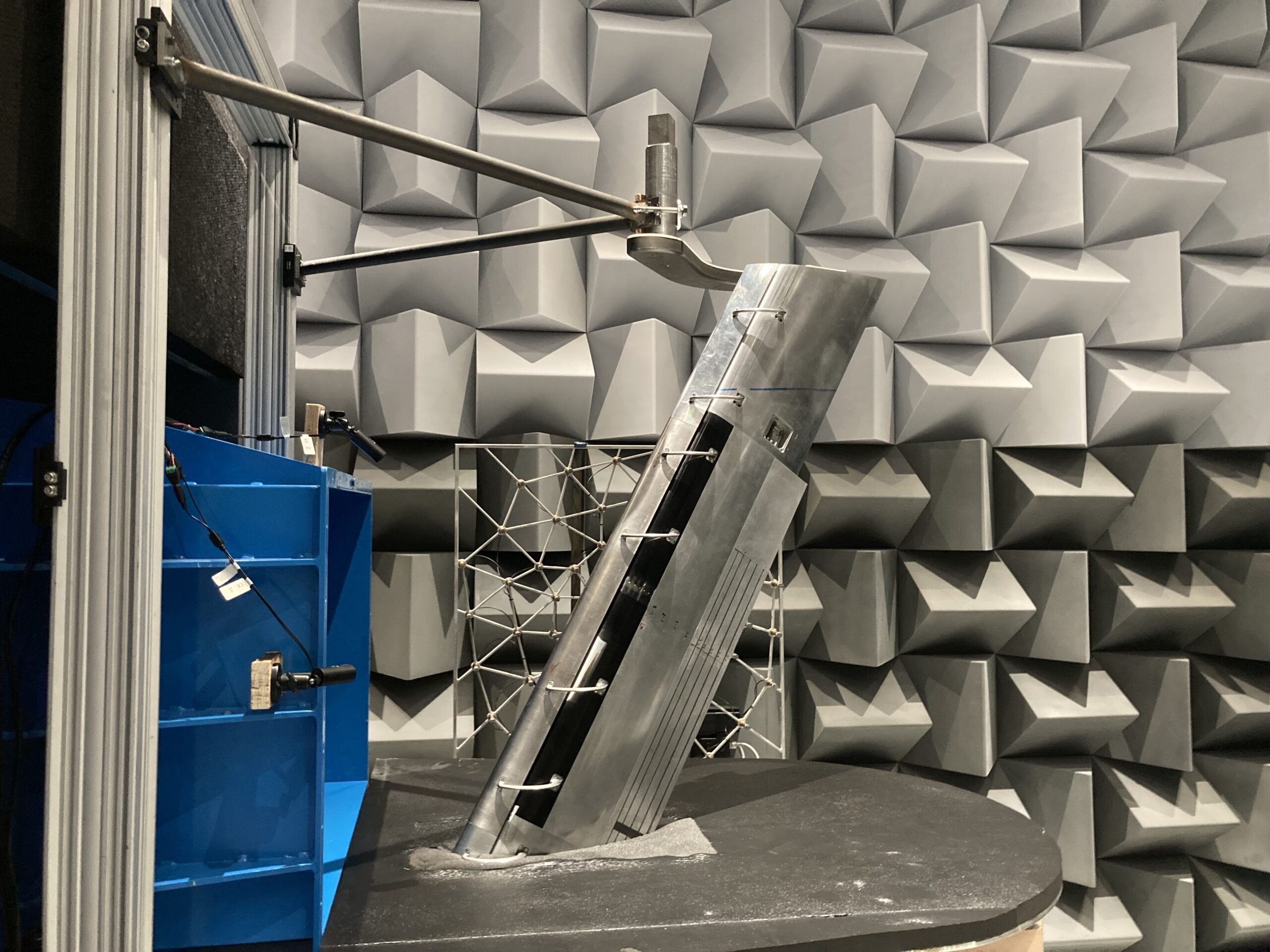

The project has developed a Scaled Flight Demonstrator (SFD) of a scaled reference aircraft (A320, scale 1:8,5), which is representative for the full-scale aircraft at Mach 0.4. SFD flight test data is measured to show that scaled flight-testing can be used for obtaining flight-mechanics characteristics that are representative of the full-scale aircraft.

What did we do?

The work included avionics subsystem design & manufacturing & test, SFD airframe (wing & fuselage) design & manufacturing & assembly & integration (with Orange Aircraft), integration of Flight Test Instrumentation (developed by NLR), development of and integration with the Ground Control System (with CIRA), SFD system integration and test, wind tunnel tests at DNW LLF (April 2021), qualification of an operational concept to obtain an authorisation to fly, and training of the flight crew. High-speed taxi tests were performed at Deelen, the Netherlands, in November 2021

A Flight Readiness Review has been conducted successfully, with Airbus as an important reviewer. The first SFD flight as part of a qualification campaign at Deelen will be performed in the first half of 2022. The mission flight campaign in Italy is planned for mid-2022. All results will be used by ONERA to compile a final report and validate the concept of scaled flight testing as a viable means for future aircraft development

Project partners:

Industry (NL): Airbus, ONERA, Royal NLR, CIRA, TU Delft and Orange Aerospace B.V.

The SFD is developed by a partnership of Airbus, NLR, ONERA, and CIRA, with support of Orange Aerospace. This development has received funding from the Clean Sky 2 Joint Undertaking (JU) under the European Union’s Horizon 2020 research and innovation programme under grant agreements No 717183 and 945583.