At the forefront of innovation in metal additive manufacturing (AM), the Netherlands’ premier Metal Additive Manufacturing Technology Centre, MAMTeC, is driving advancements in the field. Backed by a multidisciplinary team of researchers and a wealth of experience in powder bed fusion and deposition techniques, MAMTeC is uniquely positioned to support the development of complex components and the processing of challenging alloys, including multi-material fabrication.

Qualified processes and certified parts are essential for metal additive manufacturing (AM) applications, particularly in industries like aerospace, oil & gas, and defence, where reduced weight, increased efficiency, and lead times are beneficial. With expertise in aerospace certification and qualification processes, numerical simulation, material characterisation, and metallurgy, MAMTeC is an ideal partner for organisations seeking to develop novel AM parts, processes, and repair activities.

Design, modelling and simulation

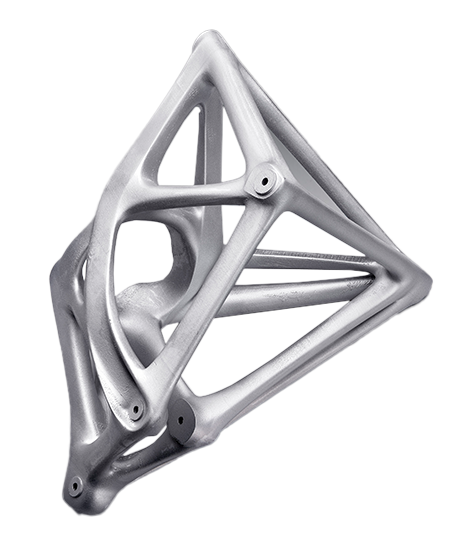

- Application of topology optimisation to get maximum benefit out of your AM-part in terms of weight reduction, lead time, cost and performance.

- Application of thermomechanical simulations to predict thermal variations, residual stresses and part deformation.

- Development and evaluation of numerical simulation tools to generate optimised variable process parameters to reduce temperature variations and produce materials with homogeneous mechanical properties.

- Development of in-situ process monitoring for validation of numerical models, monitoring process stability and detection of anomalies.

Materials

- Characterisation and evaluation of mechanical properties both static and fatigue, as well as relating this to the material microstructure.

- AM process development and optimisation for challenging alloys, including magnesium alloys and multi-materials.

Qualification and certification

- Establishing procedures for certifying metal AM products to ensure compliance with industry standards.

- Development of a process-based qualification approach based on simulation

Applications

- Being your sparring partner to develop challenging metal AM applications to meet specific needs.

- Conducting trade-off studies to evaluate the benefits and drawbacks of metal additive manufacturing versus conventional processes, including repair of worn-out parts.