Evaluation of NH-90 simulation device compliance

The challenge

The purpose is to perform evaluations of the compliance of the NH-90 simulation devices with their respective regulations and/or standards. The NH-90 simulation can be split into two separate devices that can be used separately for specific crew training and combined for full mission flight training.

- Full Flight Simulator (FFS) used for pilot training

- Virtual Sensor Trainer (VST) used for sensor operator training

- Full Mission Flight Trainer (FMFT), used for mission training with pilots, tactical coordinators and sensor operators.

The solution

The result of the project will be an evaluation process (including V&V reports) making it possible to determine:

- Whether the NH-90 FFS, VST, and FMFT are performing in accordance with the relevant regulations that will ensure safe operation of the NH-90 and its subsystems

- Whether devices are suitable for training pilots, sensor operators and tactical coordinators in both individual tasks and mission settings.

What did we do?

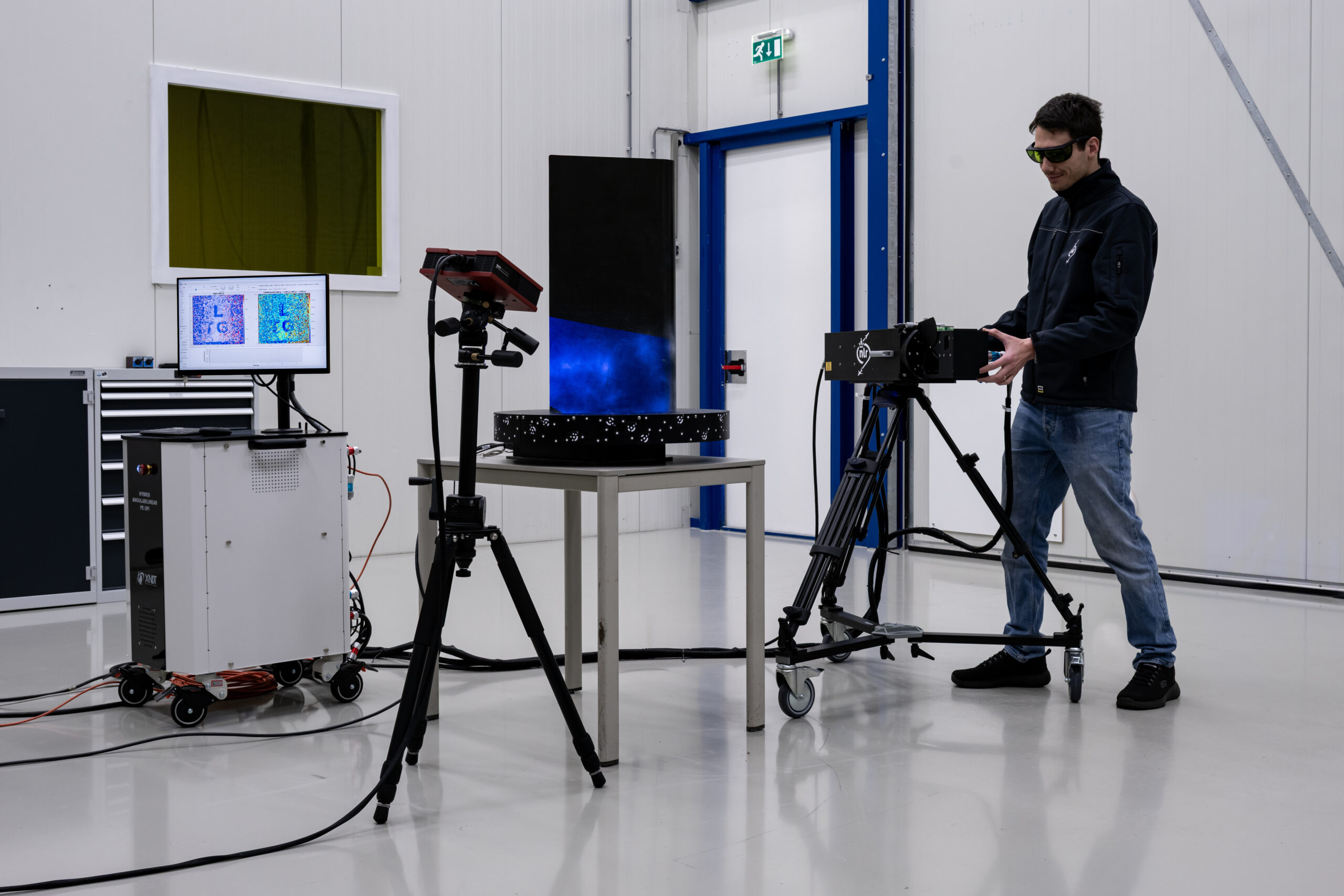

For evaluation of the FFS, the NLR evaluation team will first assess the Qualification Test Guide (QTG) of the FFS. Based on the results of this appraisement, the project team will determine if an onsite evaluation can be conducted. That will take several days during which the devices are assessed objectively by rerunning QTG tests, functionally, and subjectively as per the regulation set. The VST cannot provide objective data, so all tests performed on the VST will be subjective and functional tests.

Furthermore, the military aspects of the devices are not accounted for in the civil regulations agreed between the simulator operator and the manufacturer. To gain an understanding of the military/tactical capabilities of the devices, interviews will be conducted with experts of all crew types involved in operations on the devices.

Project partners:

Government (NL): Project Bureau NH-90, Test Flight Office

Research organisation: Royal NLR

Duration: July 2014 – ongoing