R&D cases

Filter

Explore our R&D cases

NLR is actively involved in various research projects and programmes in the Netherlands, Europe, and globally. As an independent aerospace research institute, we conduct applied research, focusing on a practical approach and innovative solutions. These R&D cases provide an insight into the diverse range of research activities and the projects we have been involved.

26 November 2025

R&D case: Hydrogen drone research

Project: HYDRA II (Hydrogen Drone Research Aircraft)

21 October 2025

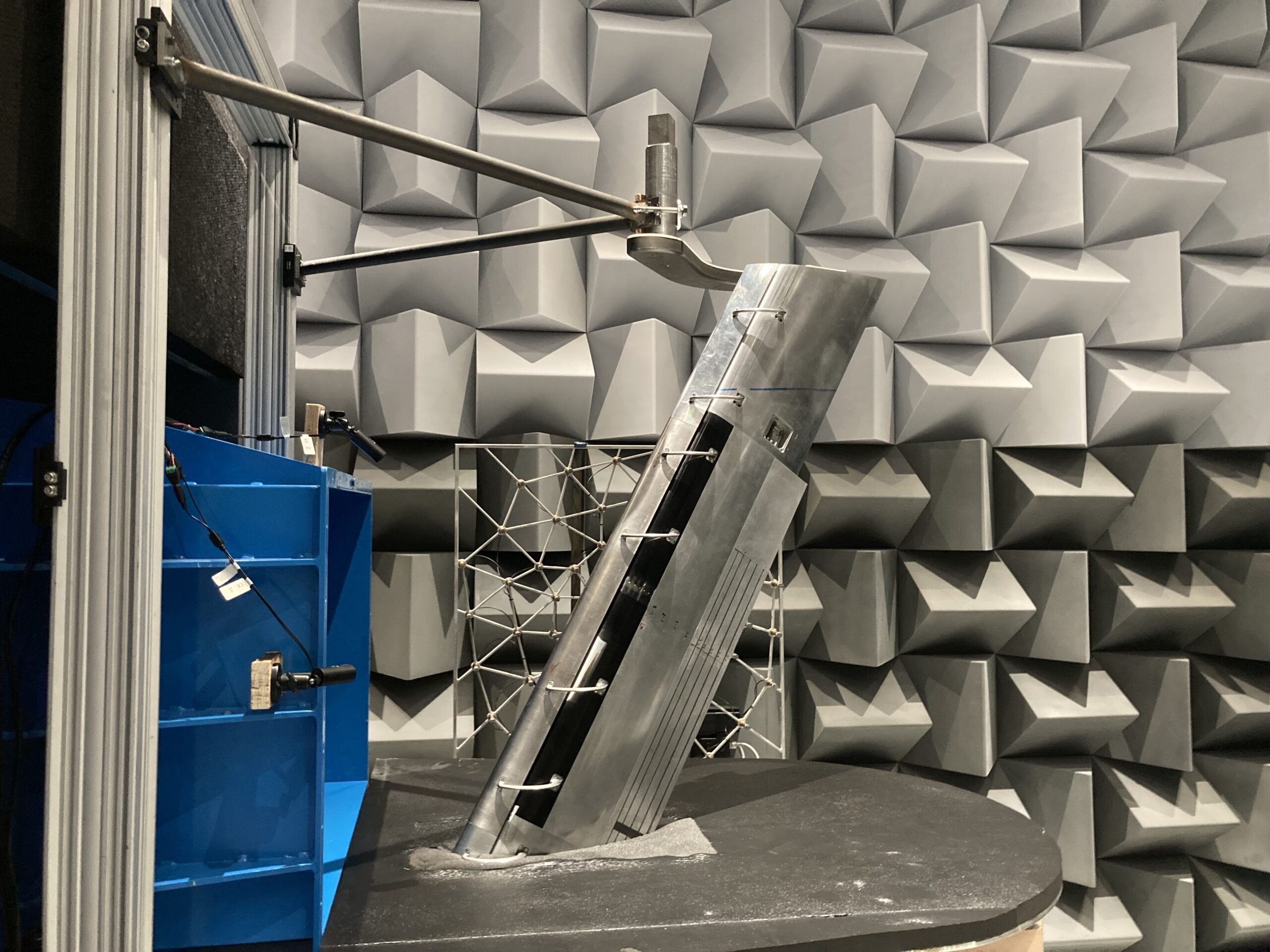

R&D case: Innovative airframe component designs for reducing aircraft noise

Project: INVENTOR (Innovative design of installed airframe components for aircraft noise reduction)

29 September 2025

R&D case: Integration and certification of LIG Nex1’s AESA radar using NLR’s Cessna Citation II

Project: FLANS (Flight test LIGNex1 AESA NLR Support)

29 August 2025

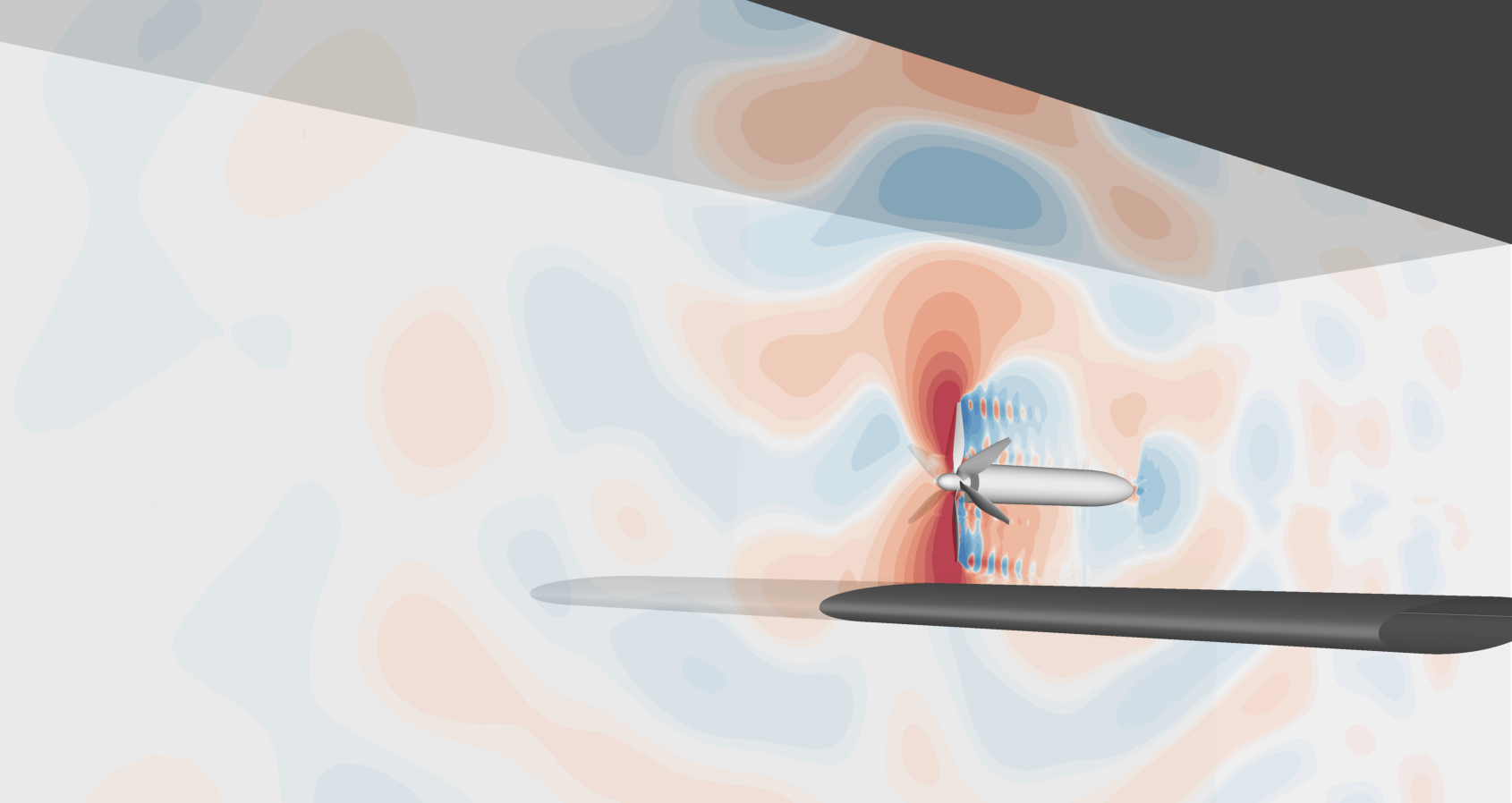

R&D case: Optimising disruptive airframe-propulsion integration concepts

Project: ENODISE (Enabling optimised disruptive airframe-propulsion integration concepts)

24 June 2025

R&D case: Breakthrough fuel cell technologies for aircraft

Project: BRAVA (Breakthrough fuel cell technologies for aviation)

06 June 2025

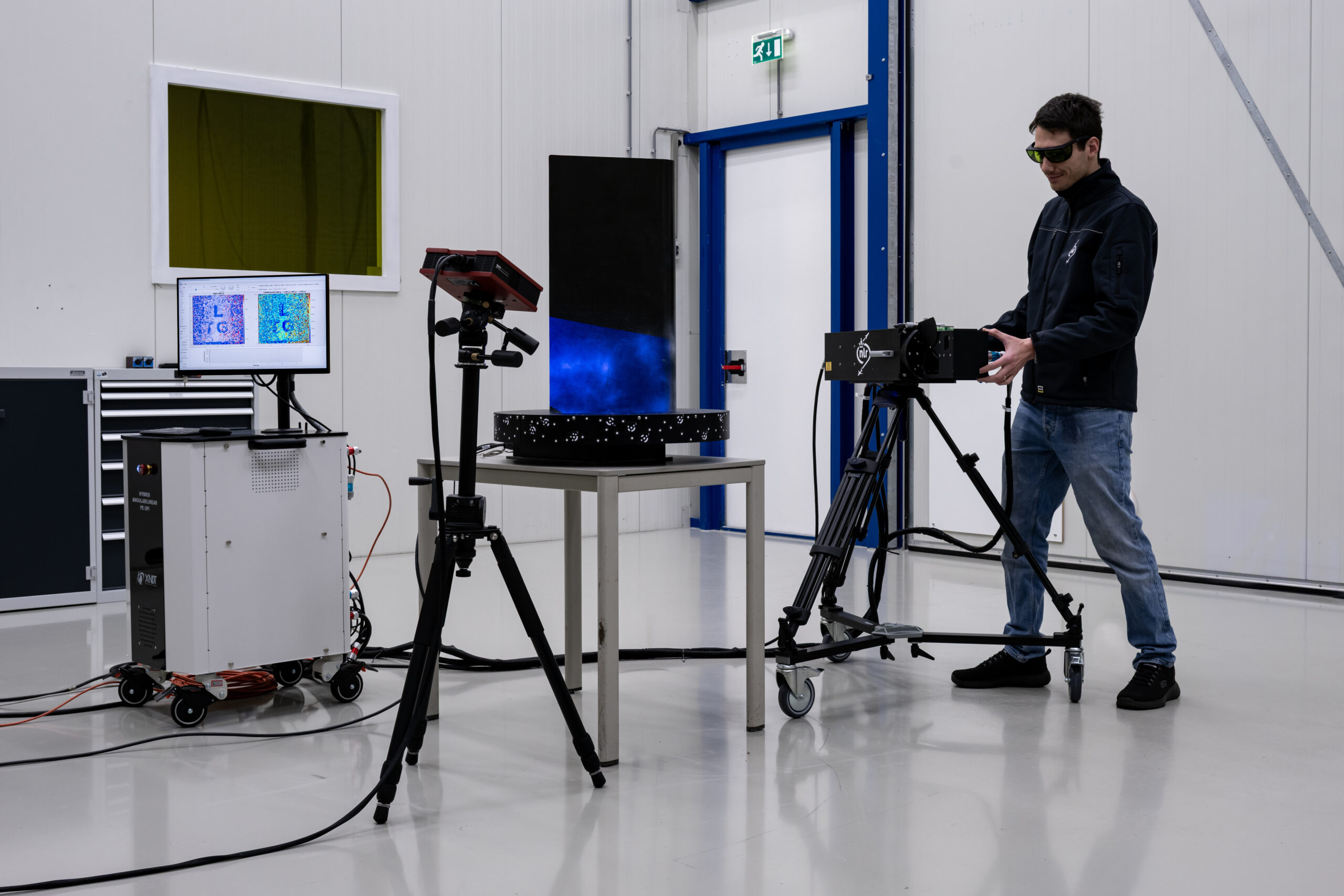

R&D case: Laser ultrasonic inspection of complex-shaped composites

The manufacturing of complex-shaped composites is becoming increasingly common, driving up demand for fast automated quality control. Laser ultrasonic testing can be a viable technique to achieve this, as it is fast and contactless. However, it requires the inspected part to be perpendicular to the laser beam, posing a challenge for the positioning of the laser or part. Combining laser ultrasonics with optical 3D scanning can overcome this challenge and realise a fast automated quality assurance system for composite manufacturing.

28 May 2025

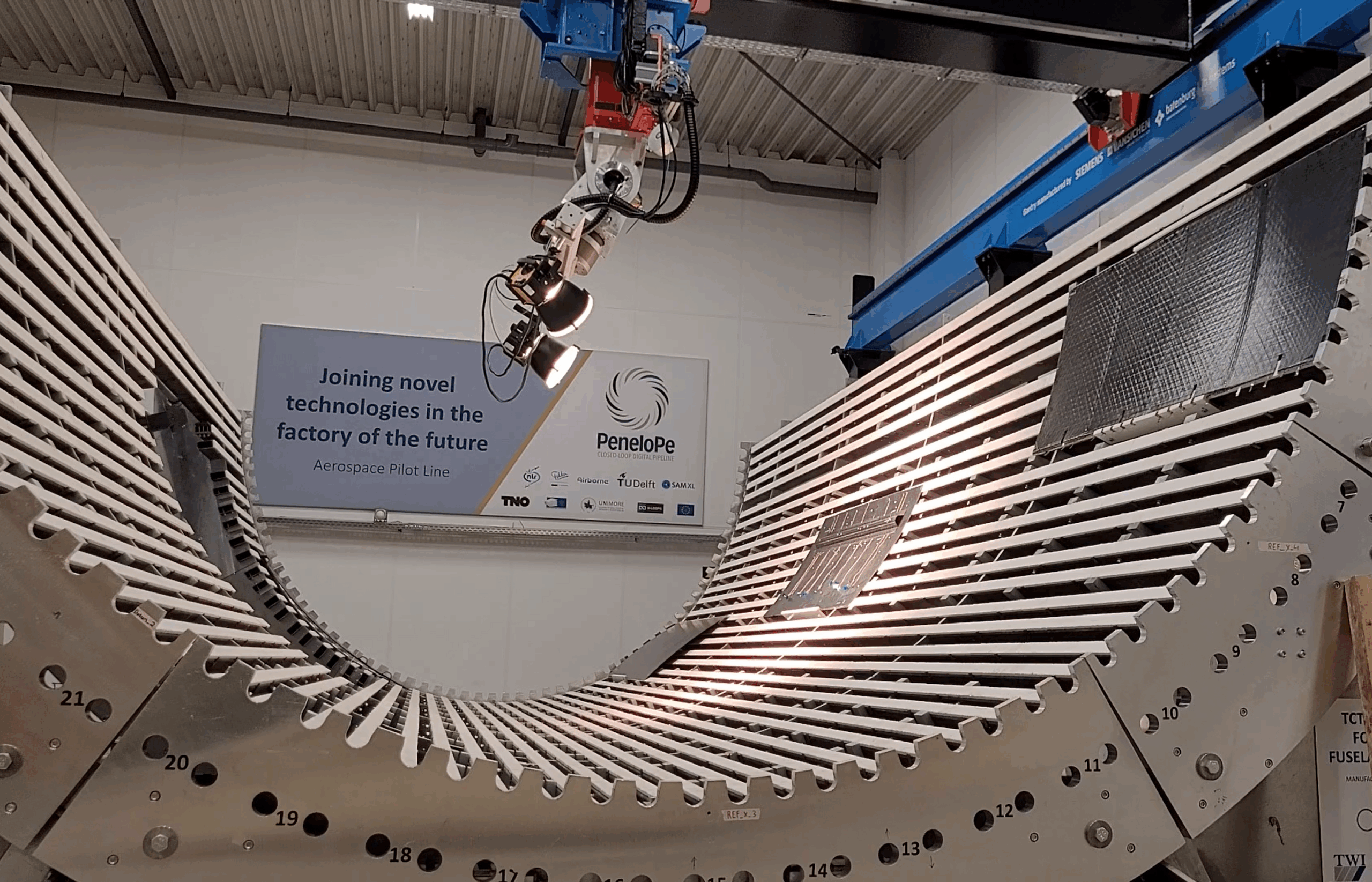

R&D case: Fast non-destructive testing of large composite aircraft structures

Project: PENELOPE (Closed-loop digital pipeline for a flexible and modular manufacturing of large components)

29 April 2025

R&D case: FLAPsense

FLAPsense project: optical sensor system for real- time proprotor FLAPping angle monitoring