Leading edge manufacturing by fibre placement with dry fibres and with prepregs

The challenge

The reduction of the CO2 emission is an important challenge for all industry and transportation sectors. To create a sustainable aerospace, several European research programmes are initiated within the Clean SKY 2 call. One of these programmes is titled Advanced Laminar Flow tAilplane, ALFA. A way to reduce CO2 emissions of aircraft is to lower the drag (the aerodynamic force that opposes an aircraft’s motion through the air). This can be obtained by creating a laminar flow over the wing. A very smooth surface is required for a laminar flow.

The solution

Within the ALFA programme Royal NLR is investigating different manufacturing techniques to create a leading edge without fasteners. One concept could be to bond the ribs to the leading edge skin. However, a fully bonded connection with fasteners is difficult to certify.

What did we do?

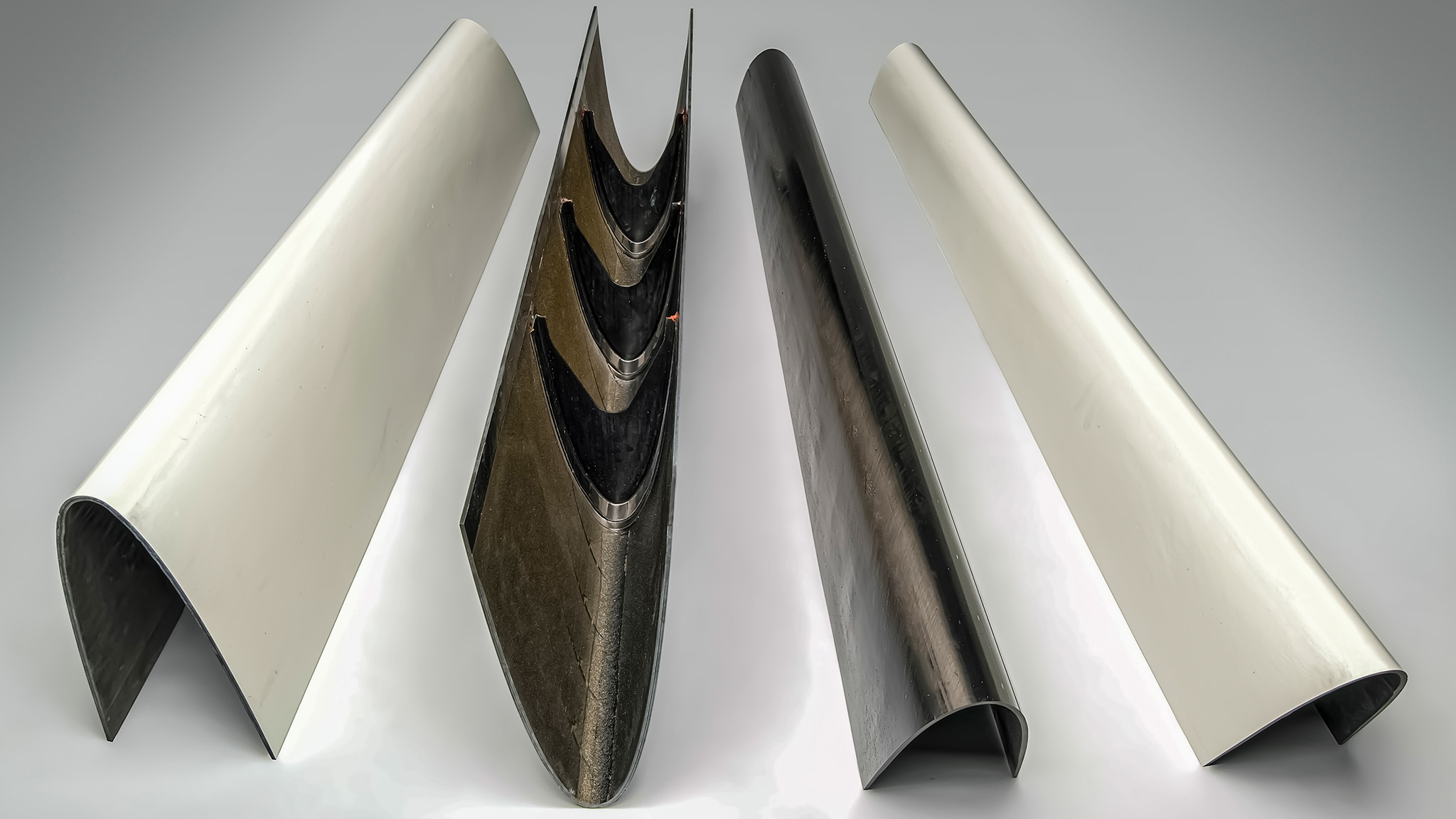

Two alternative concepts were developed: a one shot vacuum assistant resin transfer moulding VARTM process and a prepreg autoclave curing process with integrated ribs. For both processes, the preforms were made by advanced fibre placement with respectively dry fibres of prepreg tapes. The ribs were preformed from flat blanks

and vacuum press moulded to the desired 3D configuration. To create an anti-abrasive layer at the front of the leading edges, research was done together with Fichtner & Schicht for pre-treatments and electro plating of Nickel Cobalt layers.

Project partners:

Industry : Dassault Aerospace (topic manager), GKN Fokker Aerospace

Research organisations: Royal NLR

This project has received funding from the Clean Sky 2 Joint Undertaking (JU) research and innovation programme under

grant agreement no 714479