IMPACTA: An innovative cooling system for satellite electronics

The challenge

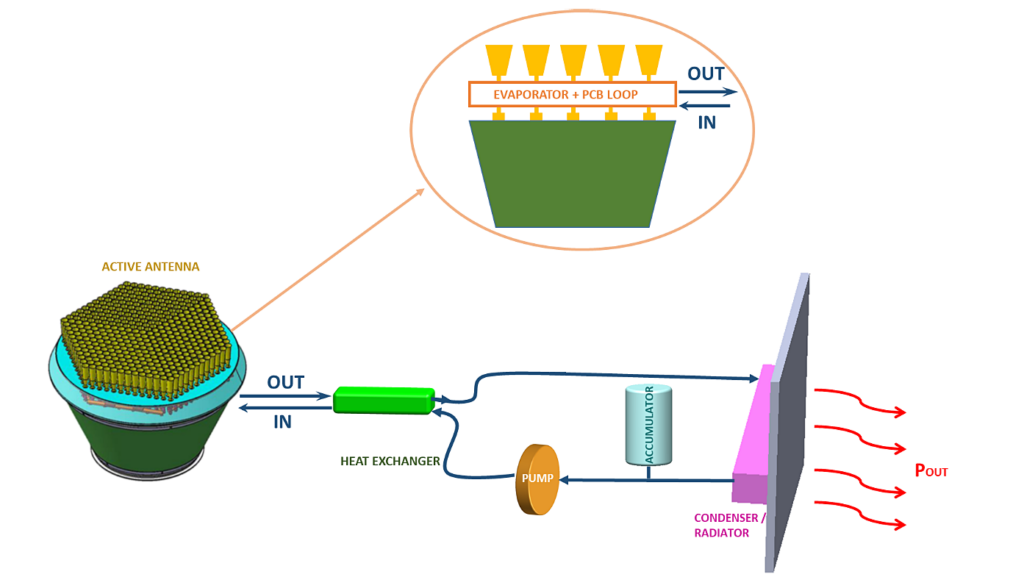

The Objective of IMPACTA is to create an innovative thermal control solution for Active Antennas that are a building block of next generation telecom satellites in Europe. This will as a consequence, solve the thermal control needs of future space missions of telecommunication. The developed technology will be transferrable other satellite payloads.

The solution

A consortium of 6 leading partners in the space and thermal industry are collaborating on this project. At NLR-side the cooling system will be modelled in NLR’s in-house two-phase cooling system model. Therein, a quantitative analysis of applicable refrigerant fluids will be done, to ultimately select the most optimal working fluid. Once a fluid is selected, the entire design of the two-phase cooling system is determined. This involves the selection of a pump, heaters, compatible materials, and the design of the evaporator. Once the design is finalized, the necessary components fabricated and assembled. This involves the usage of Additive Manufacturing for production of the evaporator section. The finalized system is then tested to assess the correct working in various situations, including a test campaign in NLR’s environmental test facilities.

What did we do?

The expertise that is built during this EU-project, will be applicable in cooling needs for the next generation of satellites.

This will enable the usage of electronics with a higher power density than currently used. Furthermore, the project has improved the TRL of two-phase cooling systems aboard satellites.

Project partners:

Industry (EU): AVS, Diabatix, Airbus D&S

Research organisations: Royal NLR , CEA, CERN

Start: 2019

Duration: 4 years

IMPACTA is co-funded by the European Union. This message doesn’t necessarily reflect the views of the EU