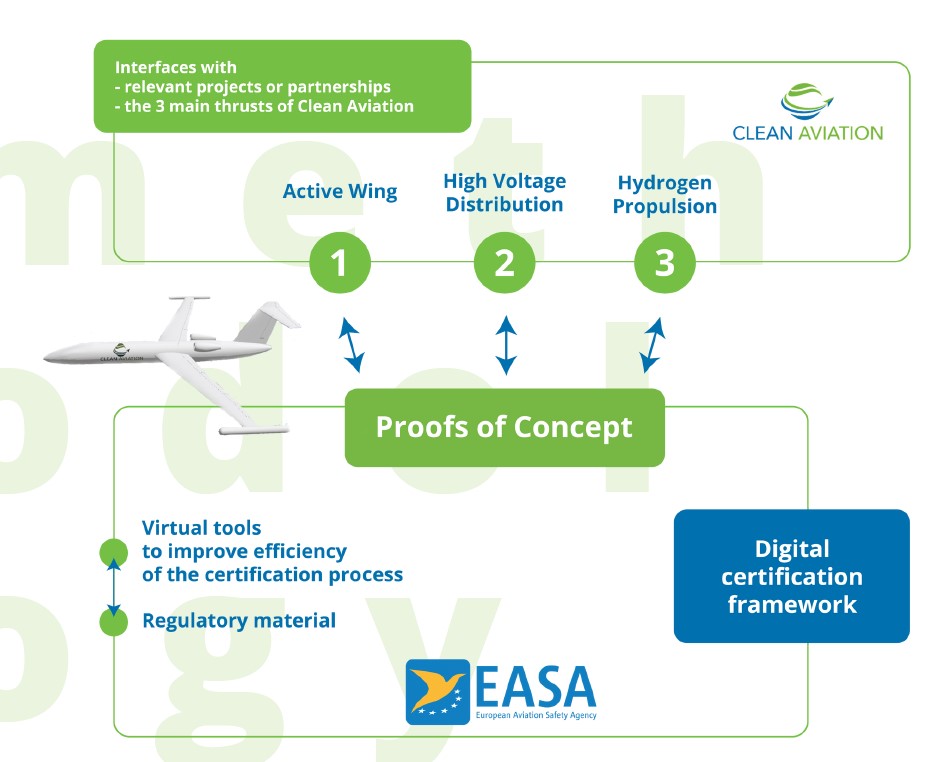

CONCERTO is aiming to develop a comprehensive set of regulations for aircraft certification, together with a preliminary description of the Methods of Compliance (MoCs) that will apply to the three main thrusts of clean aviation: Hybrid-electric regional aircraft, Ultra-efficient short and short-medium range aircraft disruptive technologies for enabling hydrogen-powered aircraft. Furthermore, it aims to assess the feasibility of a digital certification framework that will help collaboration and model-based certification.

The challenge

Certification is expected to improve safety while also shortening the time taken to get new and safe products onto the market and into service, as well as maintaining European leadership and competitiveness. The results are expected to be transferable and scalable to other product lines and aviation segments such as general aviation, rotorcraft, business jets and commercial medium-long range, affecting the entire fleet.

The solution

The certification framework can be a key enabler for reducing emissions and the target of becoming climate-neutral by 2050. The new methods and processes for certification will significantly reduce the development time and the cost of introducing new products on the market. The initiative is working on creating an ecosystem by encouraging networking throughout the aviation community, sharing common goals and developing synergies with other industries.

What we are doing

Defining safety objectives to develop rules & regulations:

- Identifying critical areas and regulatory gaps

- Identifying “gap fillers” for rules & regulations

- Tackling challenges created by the disruptive new technologies

- Proposing new regulatory material and rules

Project partners:

Dassault Aviation (project lead), NLR, DLR, TU Delft, Airbus, ONERA, Pipistrel, EASN, Safran, Collins, Leonardo, Fraunhofer, Thales, IRT Saint Exupery, Aviation Design, Arianegroup, BNAE, University of Stuttgart, University of Girona, INTA

Period: 2023 -2026

Co-funded by the European

Union. GA no 101101999