The challenge

Over the past decades the Single European Sky ATM Research (SESAR) programme has been working intensely to deliver sustainable ATM solutions. These SESAR Solutions are being brought towards higher Technology Readiness Levels (TRLs) via Industrial Research (IR) projects and towards (pre-)deployment via Very Large Demonstrations (VLDs). The challenge is to combine and integrate individually developed SESAR Solutions, while not losing the established benefits of the individual Solutions. Proper integration therefore requires a detailed understanding of the local ANSP operations and of the specific in-and-outs of the SESAR Solutions to be integrated.

The solution

The ITARO project (Integrated TMA Airport and Runway Operations, SESAR2020 PJ.37-Wave3) is a one of a kind project that combined an IR- and a VLD part to bring together several individually developed SESAR Solutions into an integrated operation, a first step towards pre-deployment. Several important validation exercise activities have been performed by Royal NLR (and partners) in the ITARO project to further close the gap between Industrial Research & Development and (pre-) deployment, aiming at greener flights and improved punctuality (e.g. less delays) contributing to more sustainable aviation.

What did we do?

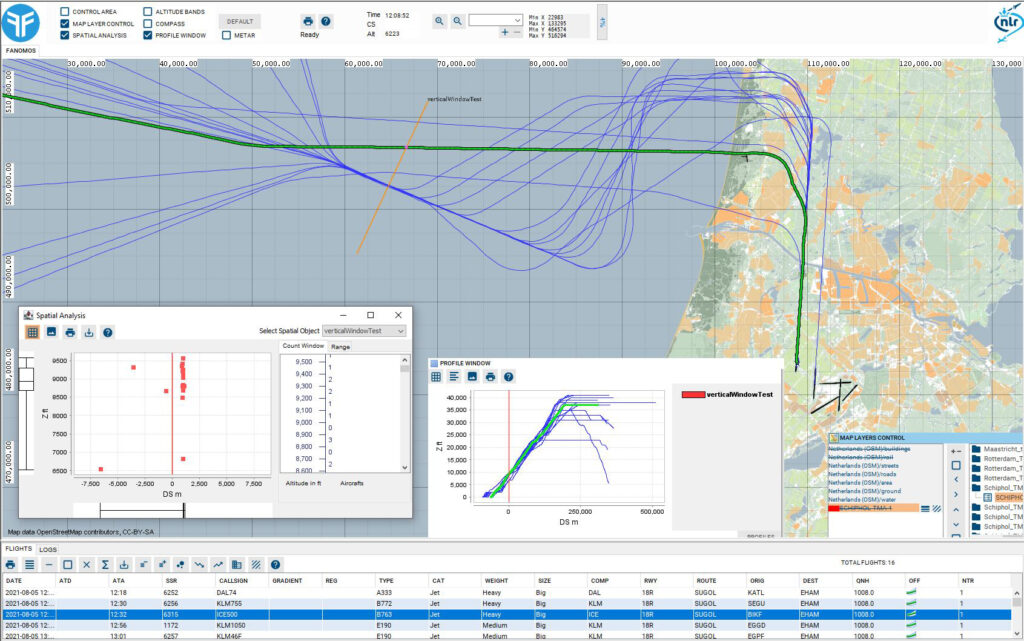

NLR has the expertise and facilities to prepare, set up, integrate and assess the performance and implication of the integrated novel SESAR Solutions for you local ANSP situation. As demonstrated in the ITARO project, the integration of novel SESAR Solutions can be assessed at for instance the Fast Time Simulations (FTS) level, a Real Time Simulation (RTS) level, or even via operations in a real live environment, for instance using a Flight Test operation, or any other means, like hardwarein- the-loop testing, etc. Royal NLR operates several facilities, like NARSIM (NLR’s ATC Research Simulator) for (remote-) tower and radar operations with ATCo in-the-loop human factors validations as

well as with dedicated tools, like FANOMOS (Flight track And Noise Monitoring System) for environmental impact studies, or with eye-trackers to measure human performance, or with PREPAIRE, allowing to set up testing scenarios. Furthermore remote coupling of NARSIM to your own simulation environment is feasible. The NLR flight test aircraft is available to bring the Solution validations to a real high TRL level with flying in a real operational ATC environment. Furthermore, Royal NLR has vast expertise to support you in several validation setup (shadowmode or other), or in your quest for answers how to properly integrate SESAR Solutions.

Project partners:

Royal NLR, DLR, NATS, EUROCONTROL, DSNA, INDRA, Paris Airport and Heathrow Airport