Integrated Steerable Antenna for Beyond Visual Line-of-sight L-band data Exchange (ISABELLE)

The market for satellite communications for Unmanned Aerial Vehicles (UAV) is expected to grow considerably in the next years. The growth of the UAV sector follows from the diversity of potential applications. Among the earliest applications of UAVs for civil use are the so-called dull, dirty or dangerous tasks (e.g. performing oil and gas exploration surveys). In order to routinely operate a UAV Beyond Visual Line Of Sight (BVLOS), one needs a SATCOM link between the UAV and the Remote Pilot Station (RPS).

The challenge

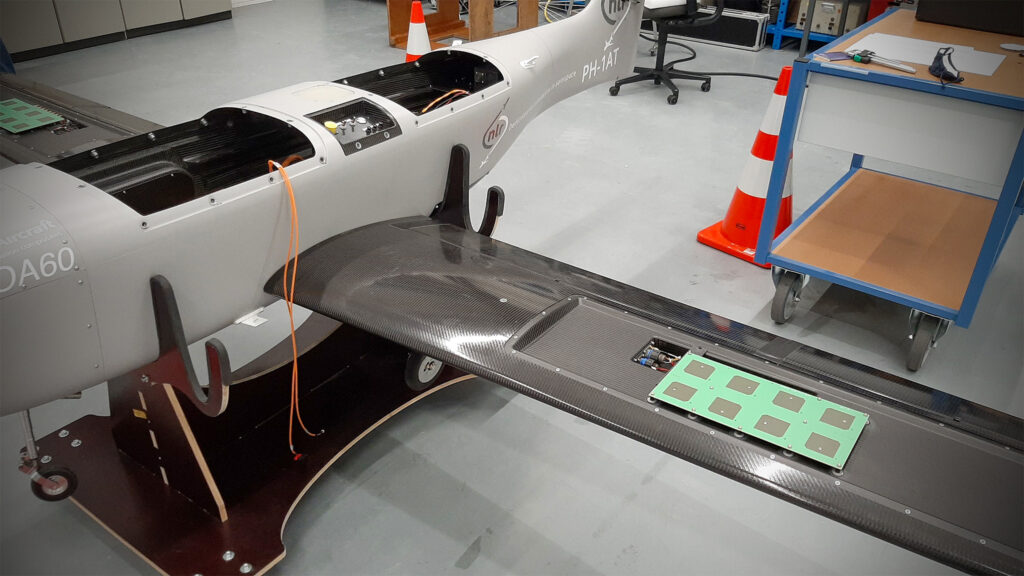

A recurring obstacle is the accommodation of any satellite antenna into small sized UAVs. Geometrical dimensions of a single antenna are an obvious consideration for interfacing with the UAV. In the project an integrated satcom array antenna has been developed.

The solution

Available surfaces such as the wing and tail can be used to integrate antenna arrays. The objective of the ISABELLE project was to demonstrate by design, manufacture and testing the viability of an embedded antenna array with real time adaptive beam forming where the antenna is integrated in the wing structure of the UAV

What did we do?

The work carried out in this project comprised:

- Providing an overview of the available satellite services and antennas for satellite communication.

- Selection of applications that benefit most of the use of the integration of antennas in the mechanical structure of the UAV.

- Defining an antenna concept, antenna architecture and antenna requirements.

- Making a preliminary design of an array antenna integrated in the wing of a UAV

- Design, manufacturing and test of a number of critical components of the antenna system.

- Manufacturing of the antenna arrays (receive and transmit), the beamformers (receive and transmit) and the antenna control.

- Measurements to characterise the manufactured components.

- Ground and flight tests.

- Writing a detailed design, development and manufacturing plan to bring the UAV antenna to production level.

Project partners:

Customer: European Space Agency (ESA)

Industry: Orange Aircraft (NL) and Barnard Microsystems Ltd. (UK)

Research organisations: Royal NLR

Start : March 2018

Duration : 3 years