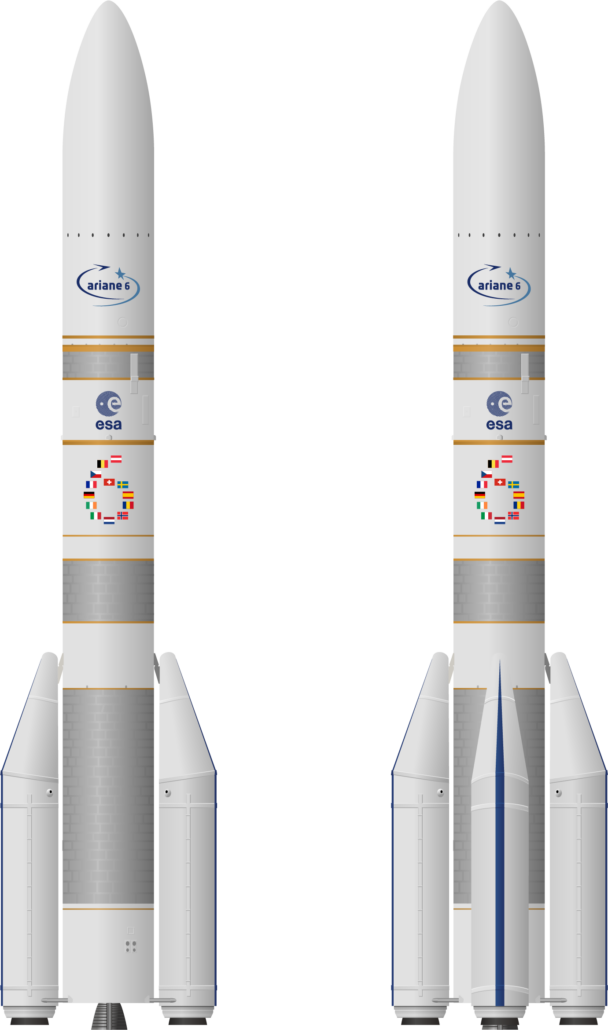

The development of the Ariane 6 launcher was geared towards creating a reliable, flexible, and competitive European launch system. NLR played an important role in this endeavour by providing wind tunnel models at various development stages.

The challenge

A key objective of the Ariane 6 programme was to devise a launch system that offered flexibility in terms of payload size and orbit delivery. Furthermore, it aimed to outdo its predecessor, Ariane 5, by increasing launch frequency and reducing costs, thereby enhancing its competitiveness.

The solution

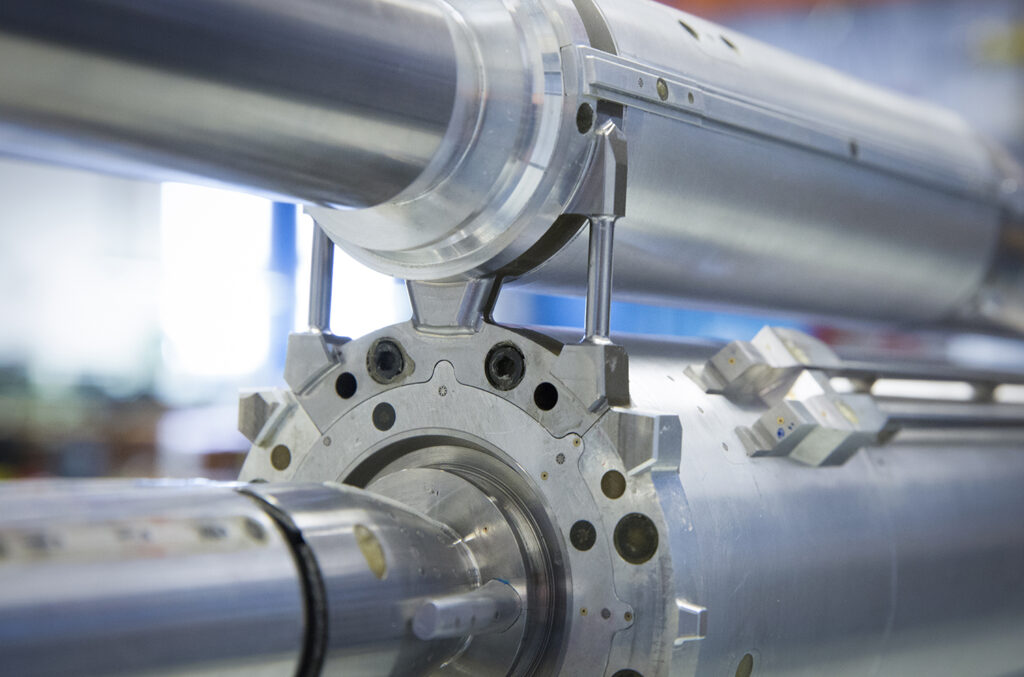

NLR’s contribution to the Ariane 6 launcher development was multifaceted, with a primary focus on providing wind tunnel models for:

- Assessing aerodynamic characteristics of the basic design

- Investigating buffeting and acoustic characteristics of the detailed aerodynamic shape

- Evaluating aerodynamic characteristics of the detailed aerodynamic shape

What we did

NLR used its expertise to design, manufacture, and equip three models with a substantial array of sensors, including static and reference dynamic pressure sensors. The limited space available in the models necessitated the optimisation of their design and instrumentation. The modular design of the instrumented boosters introduced an added layer of complexity, but also brought significant benefits in terms of functionality for ArianeGroup.

The wind tunnel tests conducted on NLR’s models provided ArianeGroup’s design teams with valuable data to refine the launcher’s architecture. This helped achieve the Ariane 6 project’s goals: creating a reliable, flexible, and competitive launcher.

Successful launch of Ariane 6 with four boosters

On 12 February 2026, the first Ariane 6 rocket with four boosters launched from Guiana Space Centre, marking a significant milestone as the first to feature four boosters and the long fairing – a nosecone that splits vertically in two. The Ariane 64 configuration, with its four boosters, doubles the rocket’s performance compared to the two-booster version, enabling it to carry around 21.6 tonnes to low Earth orbit. Furthermore, this adaptable three-stage rocket can be tailored to meet the needs of various missions by using either two or four boosters and adjusting the fairing length.

Credits: European Space Agency (ESA)

Project partners:

ArianeGroup, Royal NLR, DNW, ONERA

Project timeline

2014-2020