25 February 2025

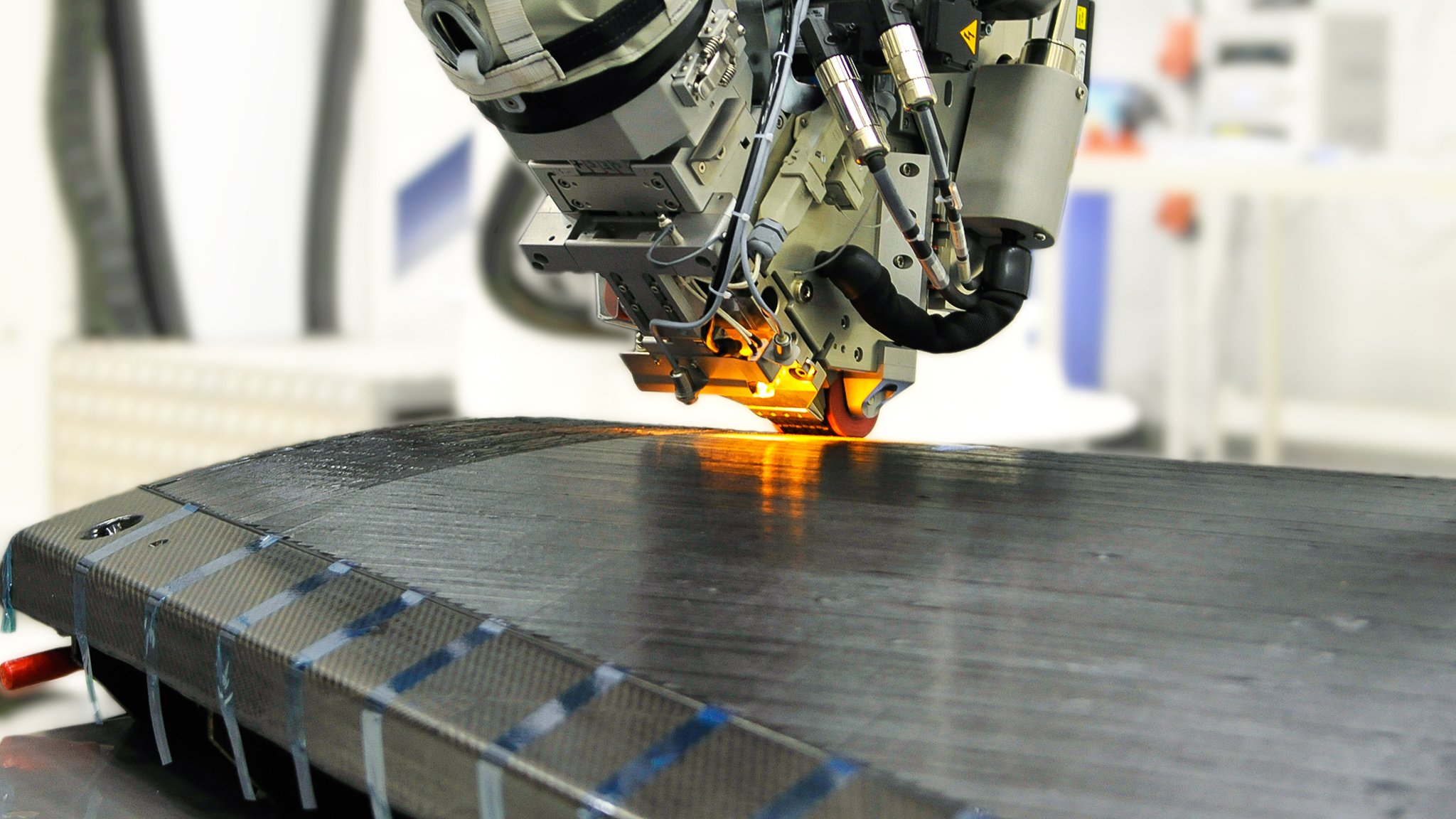

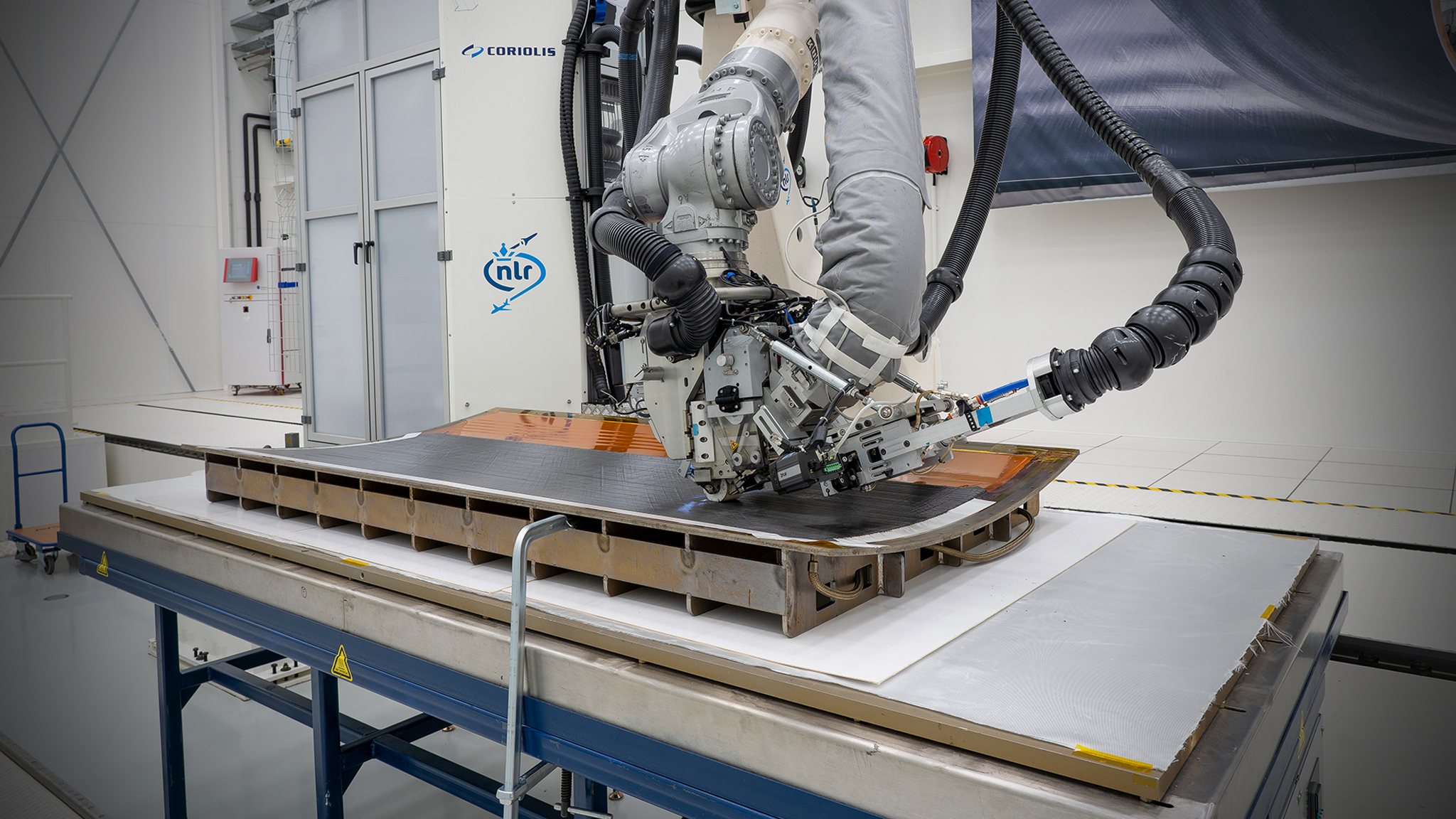

Coupon testing – materials testing

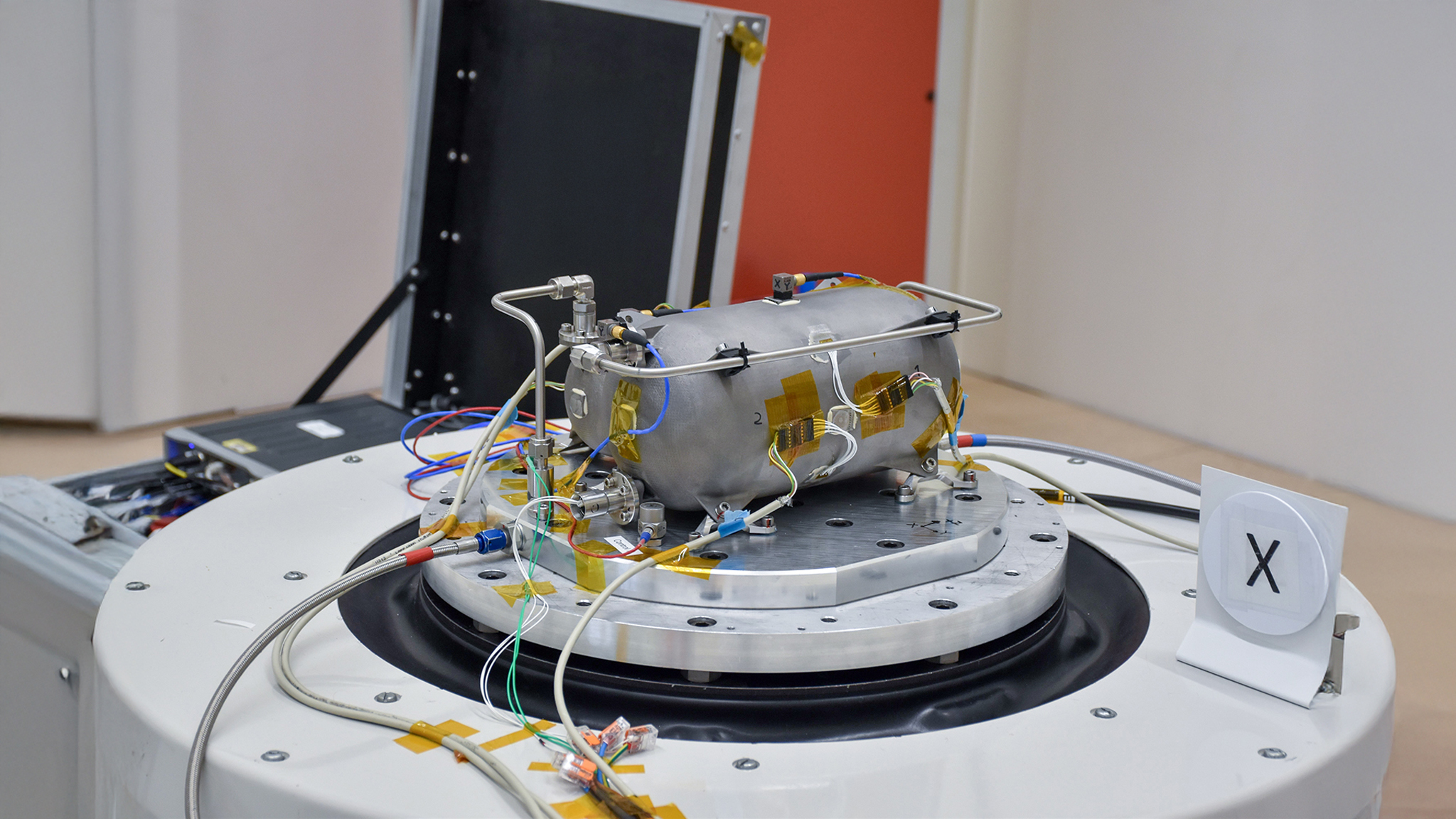

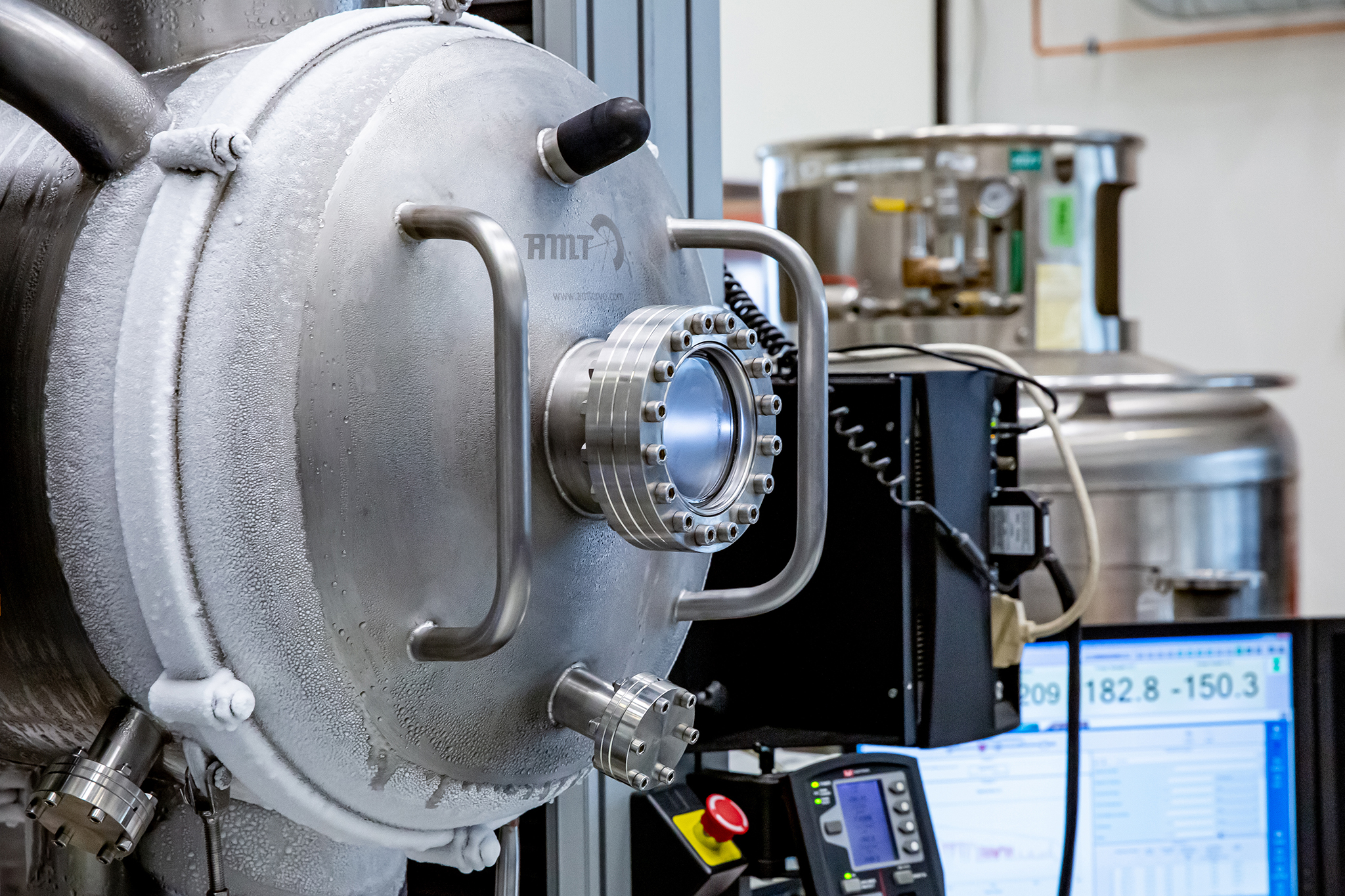

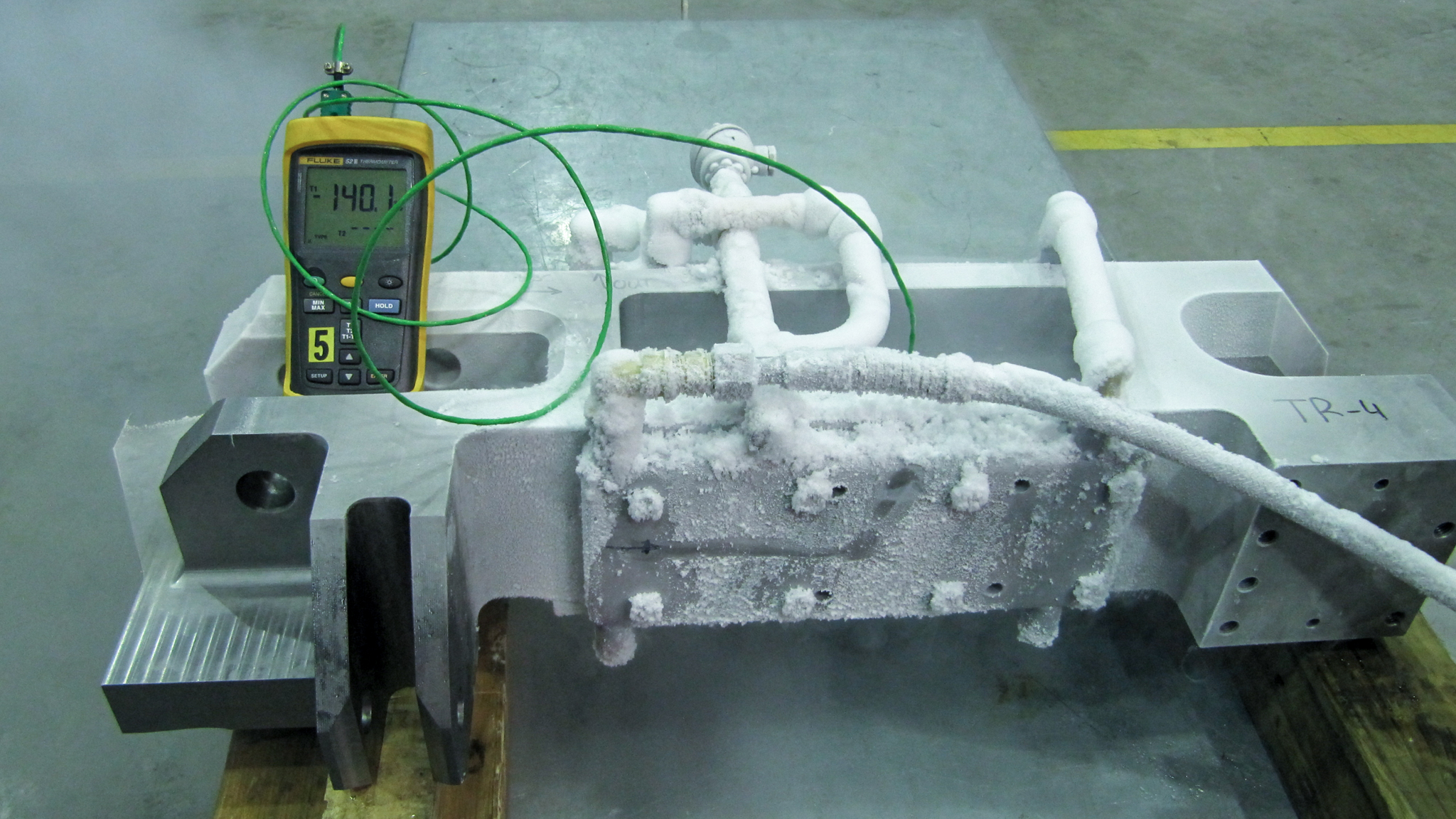

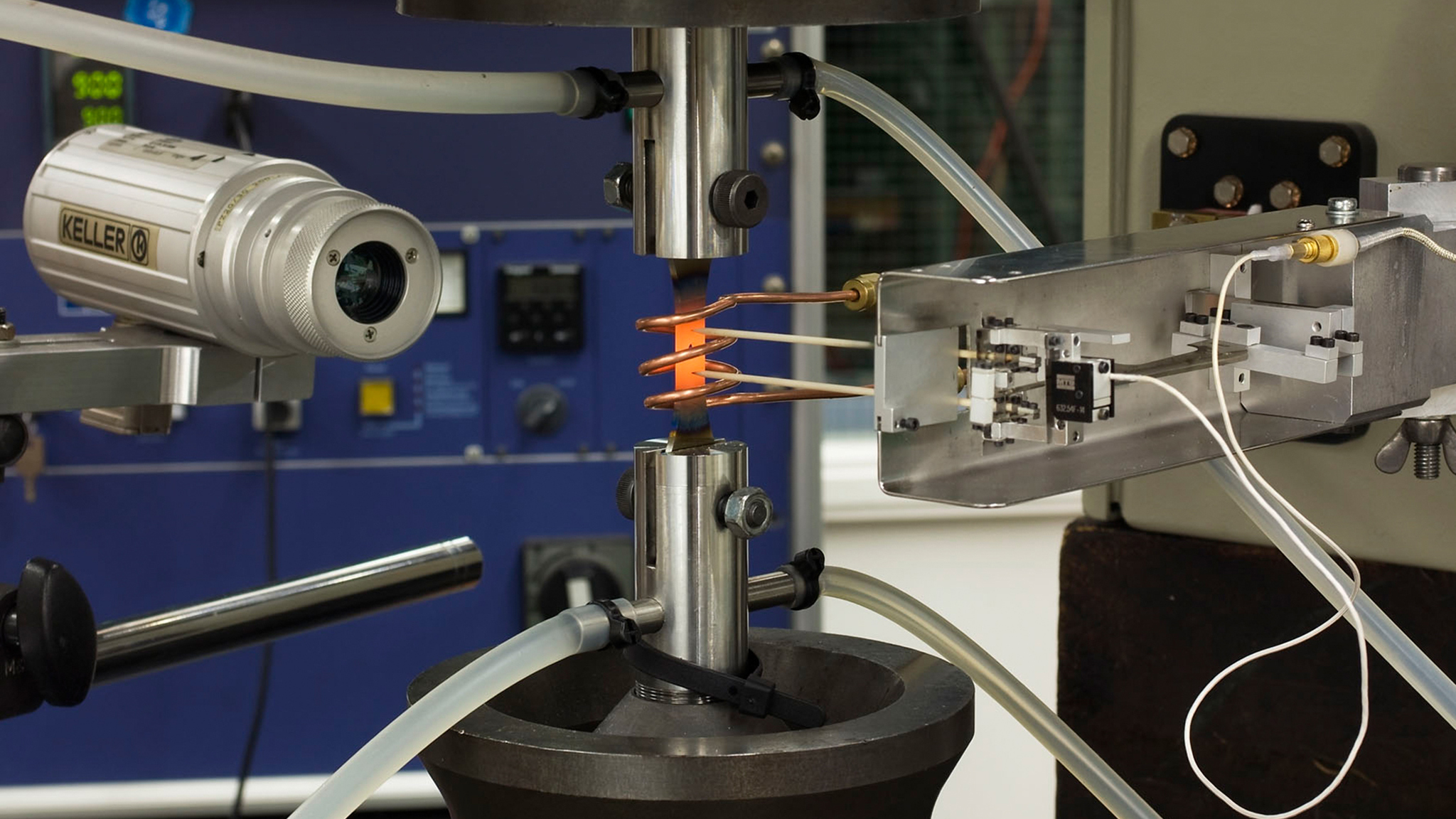

The NLR research infrastructure encompass a wide variety of coupon and materials testing, including inspection and calibration systems, ranging from creep and quasi-static to dynamic and high-frequency testing. We mimic aerospace, space and off-shore environments, civil and military, in order to conduct realistic testing. Our testing services include static, fatigue, and damage tolerance testing, all of which are performed in accordance with international standards or tailored to meet specific client requirements. Additionally, we execute material evaluation and qualification programmes.

We can accommodate a wide range of environmental conditions to meet your specific testing needs, including ambient, low (-55°C), cryogenic (-180°C), elevated (80°C), and high-temperature (1250°C) environments, as well as controlled humidity, corrosion, and saturation conditions.