11 March 2024

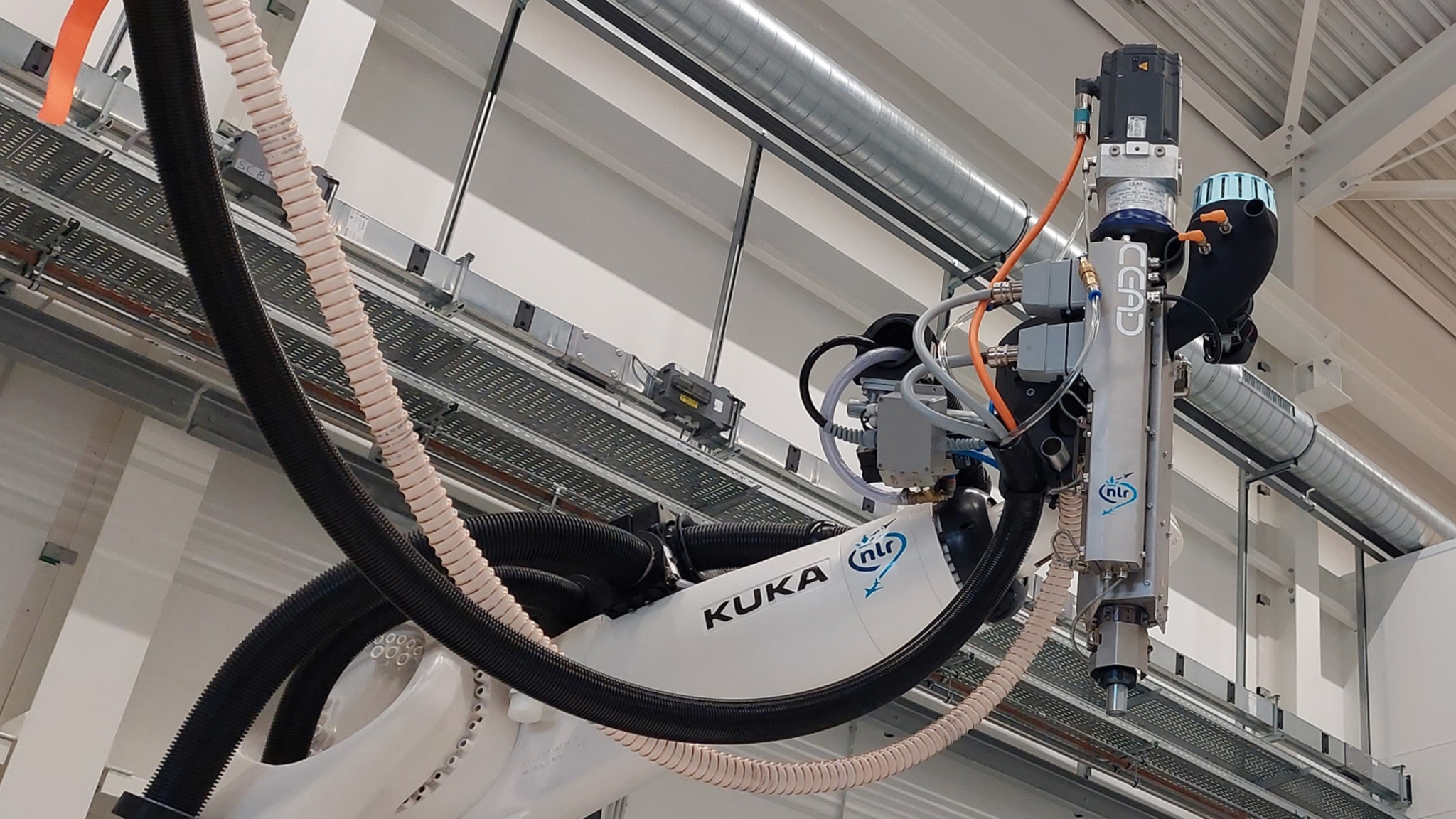

R&D case: Advanced Laminar Flow tAilplane (ALFA)

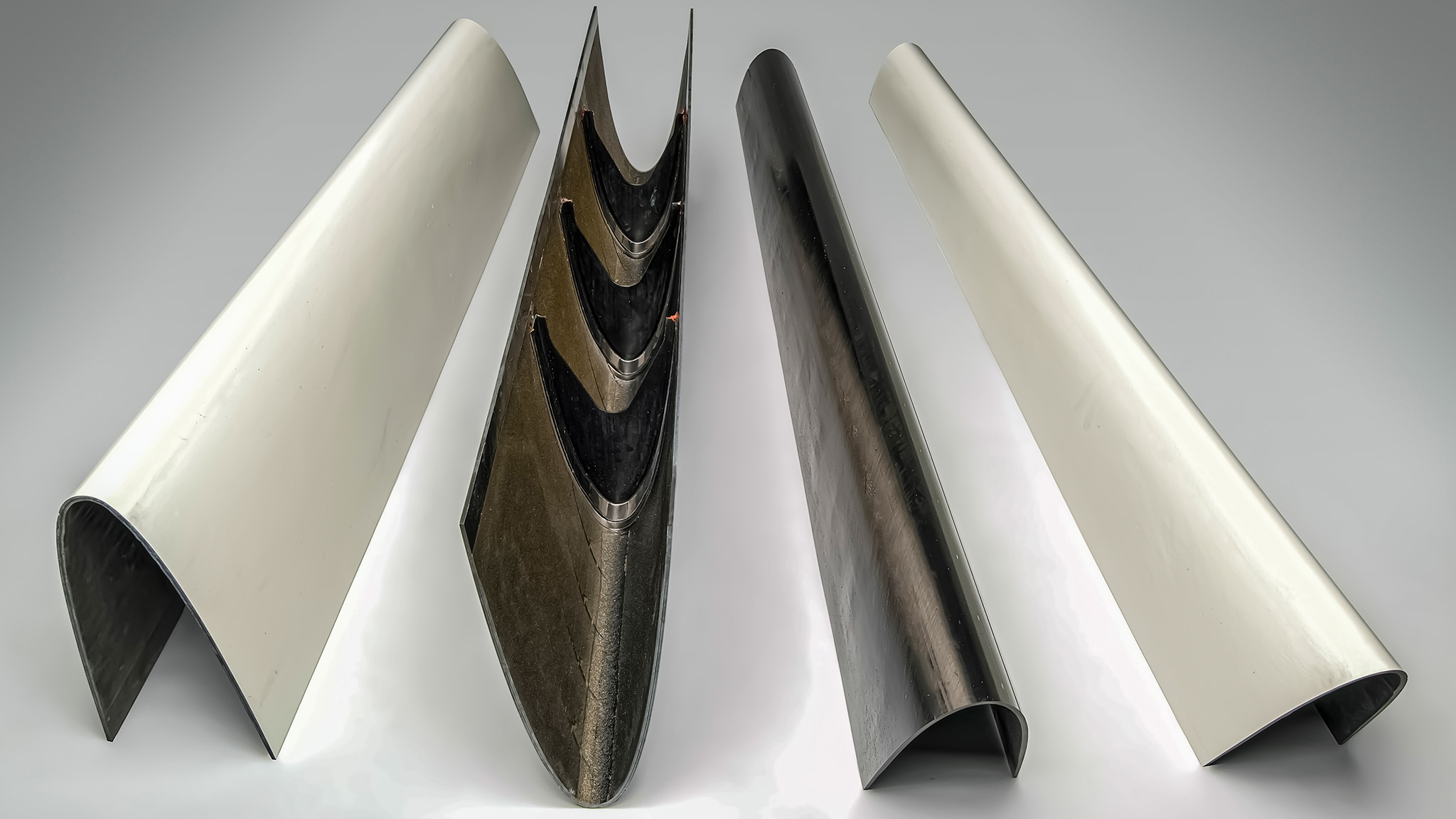

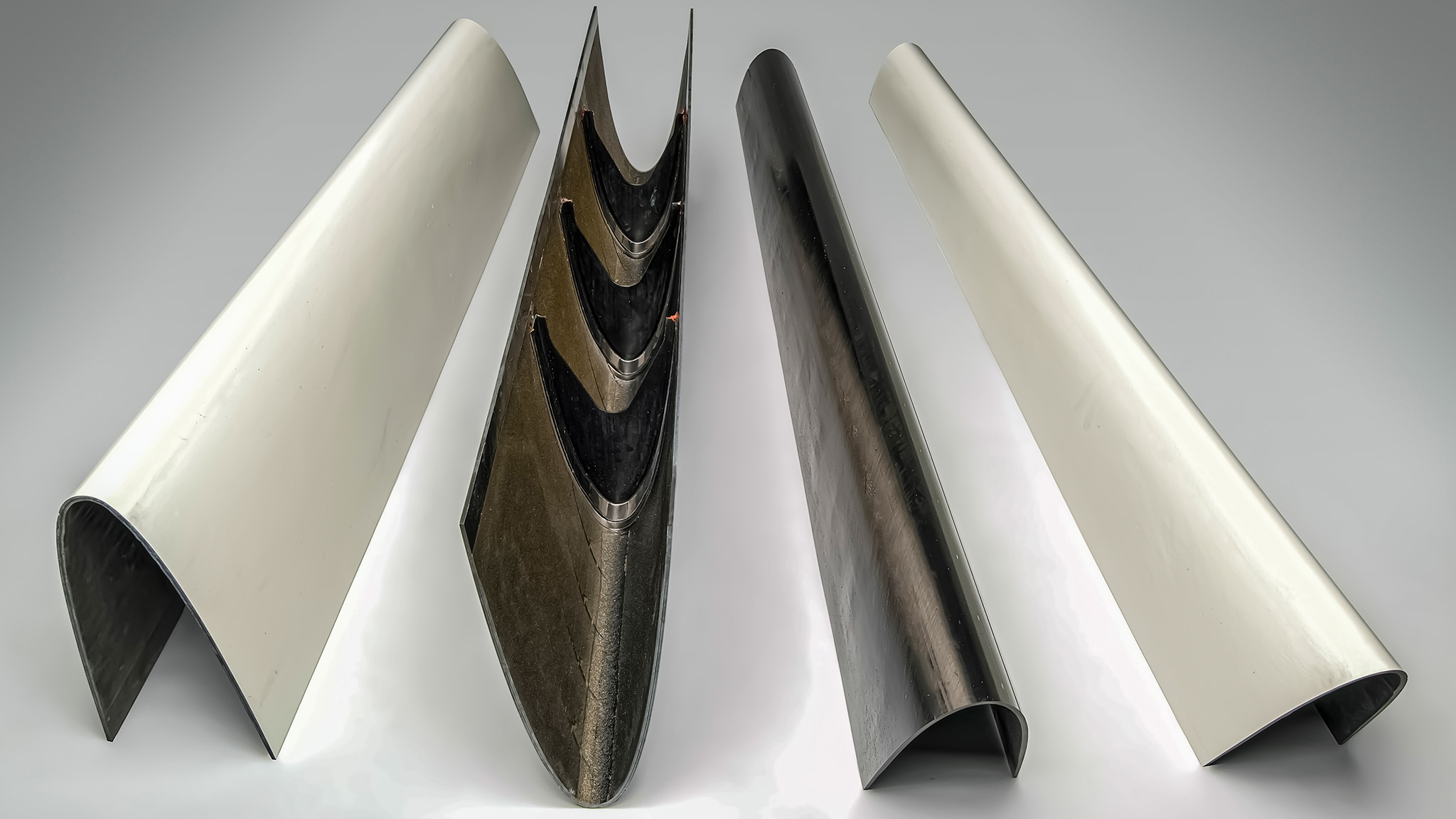

Leading edge manufacturing by fibre placement with dry fibres and with prepregs

11 March 2024

Leading edge manufacturing by fibre placement with dry fibres and with prepregs

04 March 2024

Large-Scale Additive Manufacturing (LSAM) can deliver enhanced efficiency, cost-effectiveness and design flexibility for composites cure tooling for Aerospace applications. For a while now NLR operates its own LSAM setup with success and actively participates in various projects dedicated to exploring this process. In a whitepaper NLR addresses the complexities and challenges but it also elaborates on how to make use of the full potential of the LSAM technology.

28 February 2024

Co-funded by the European Commission the COMPASS project aims to revolutionise the remanufacturing of end-of-life parts into high quality components. This will lead to significant resource savings and promote a circular economy approach in the aerospace and automotive industries.

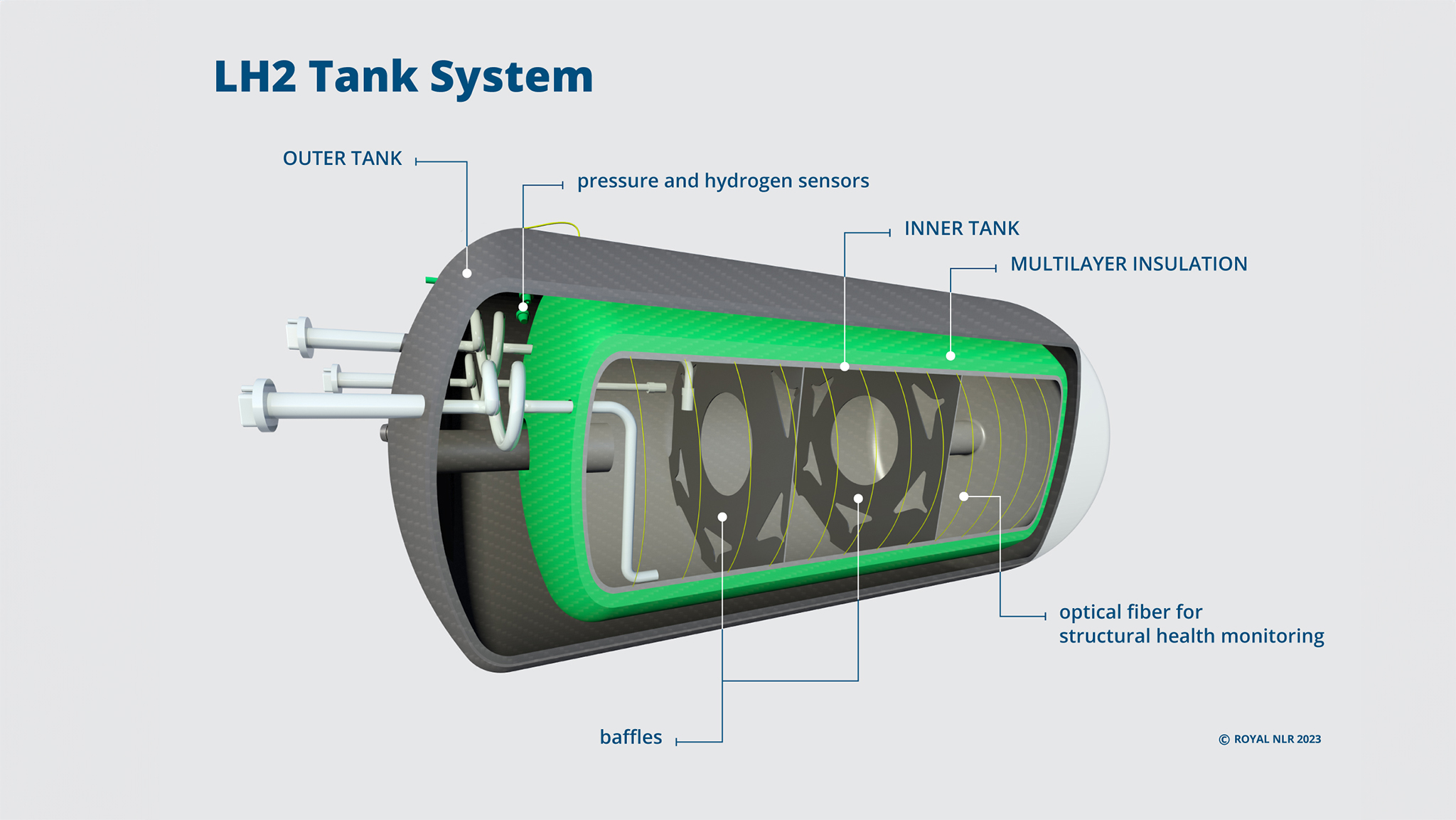

04 July 2023

Hydrogen has been identified as a key priority to achieve the European Green Deal for a sustainable economy. By converting the construction of the hydrogen tank from existing metallic solutions to composites, the liquid hydrogen (LH2) composite tank will achieve weight savings that enable the advancement of liquid hydrogen as a sustainable fuel source for civil aviation. This will lower the carbon footprint of air travel and extend the flight range of aircraft by reducing construction weight and cost.

26 June 2023

During the Paris Air Show, the German ECOMAT and Royal Netherlands Aerospace Centre signed a Memorandum of Understanding. With this, the two parties want to combine their scientific and business expertise with regard to lightweight constructions, hydrogen developments, materials research and virtual product development in the aircraft manufacturing industry.

11 April 2023

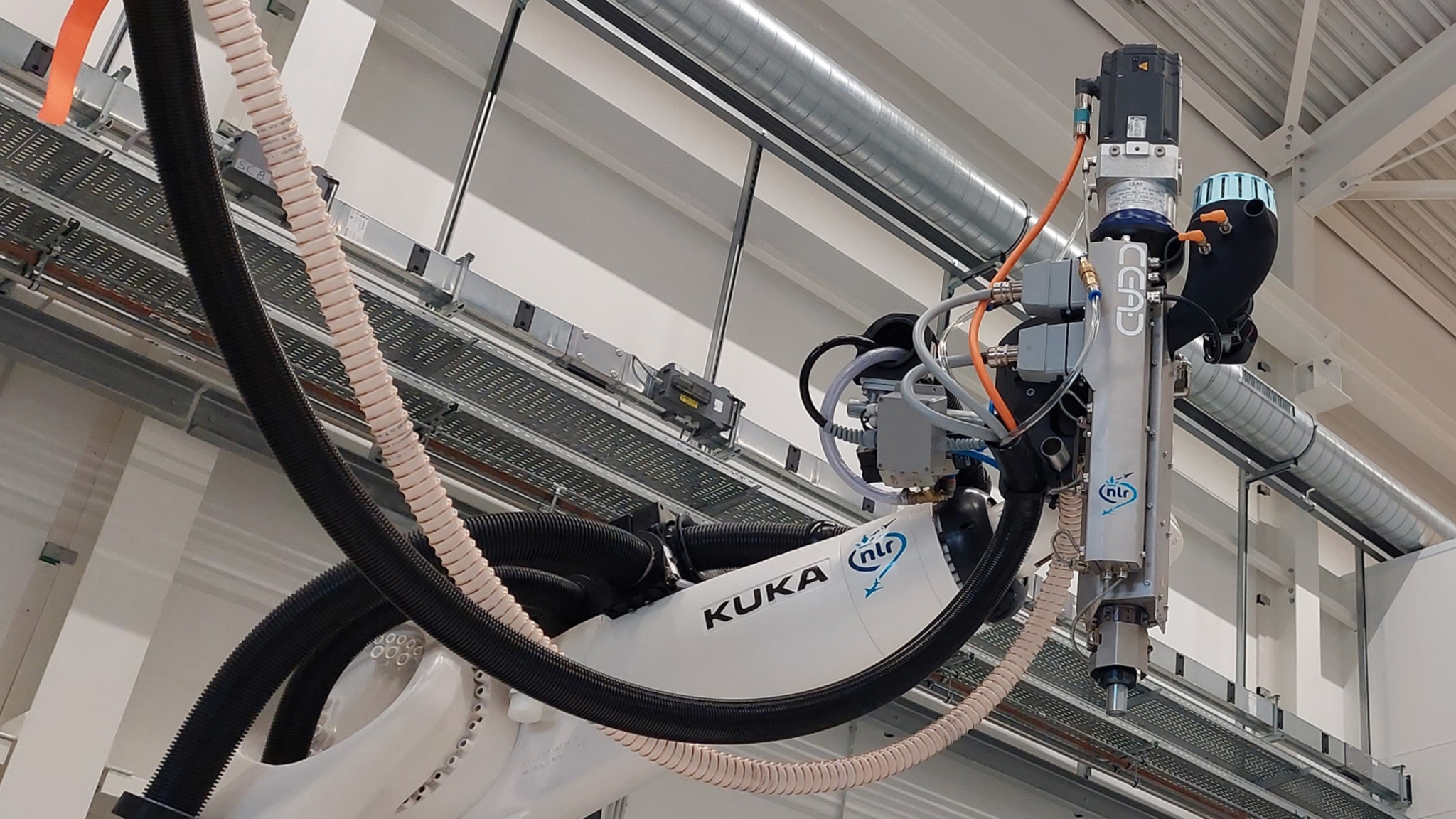

Royal NLR is aiming to improve two things at the same time: saving weight for aviation structures and speeding up their production processes. NLR is therefore exploring a relatively new technology called large-scale additive manufacturing of fibre-reinforced thermoplastic materials.

05 April 2023

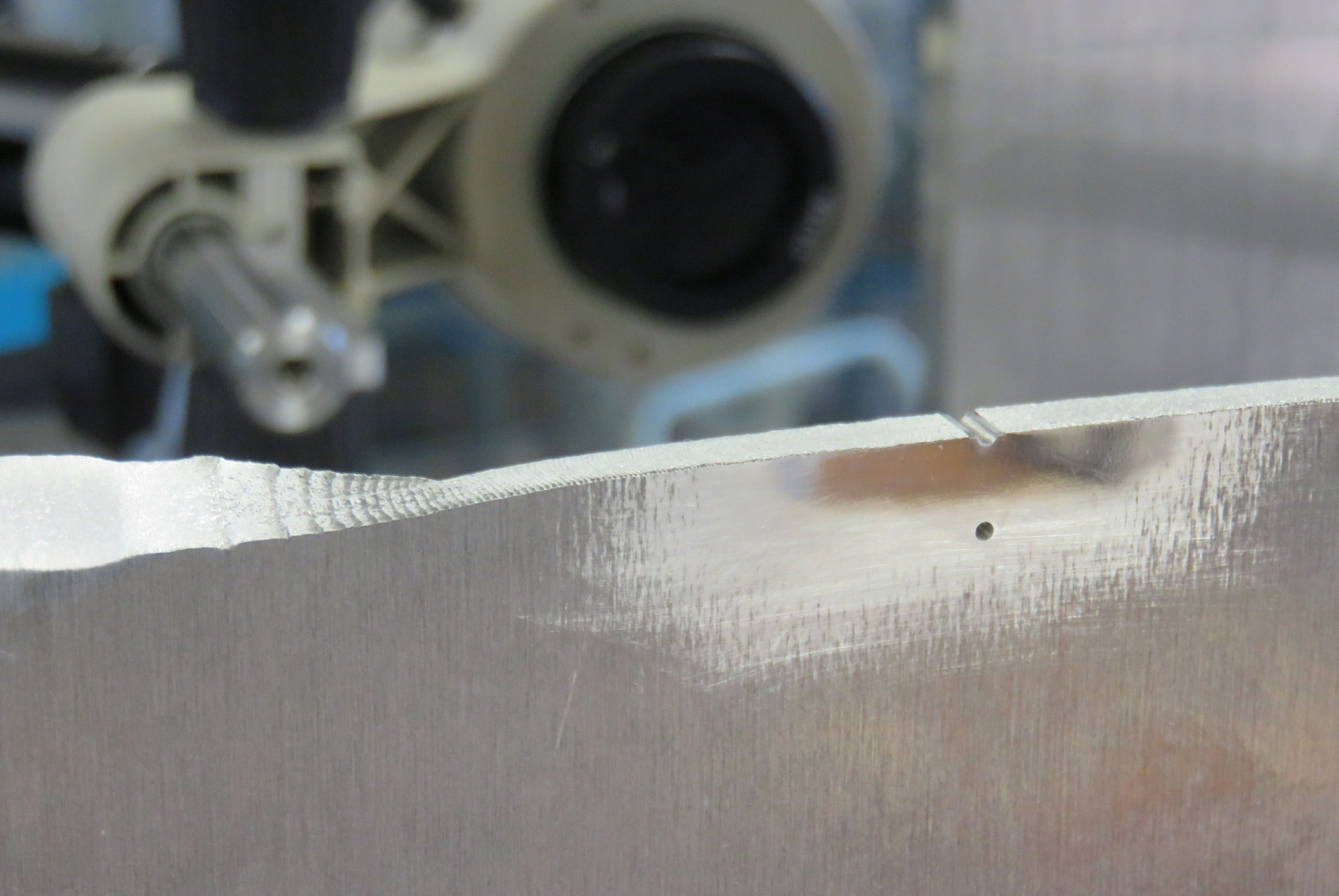

Fatigue of metals can cause premature failure of components and structures that are subject to cyclic loading. To avoid that risk, designers still employ a theory from the 1960s. Royal NLR has now come up with a new equation for calculating the growth rate of cracks under cyclic loading better. The proof of this has recently been published in the journal Engineering Fracture Mechanics.

04 April 2023

The objective was to manufacture three Ti-6Al-4V flaperon ribs by Direct Energy Deposition (DED). With conventional manufacturing processes, it can be very costly or even impossible to produce components with such complex shapes. However, DED is also challenging due to various features inherent in the design: bulky thin parts, asymmetric geometry, overhanging features etc. The main challenge was manufacturing all the structures with the minimum distortion and highest accuracy.