10 October 2019

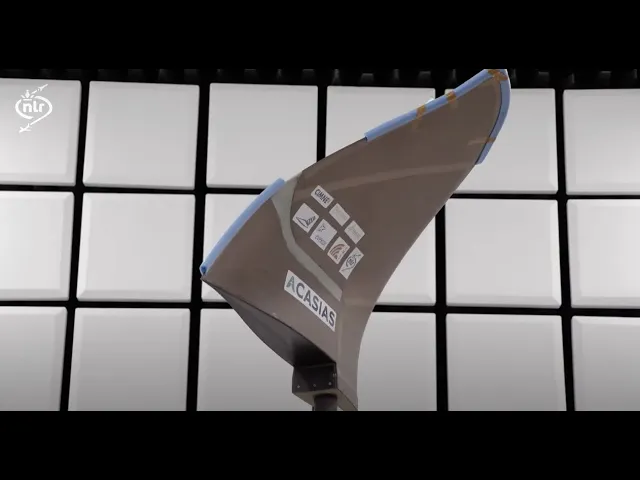

Beamforming antennas (also known as phased-array or beamsteering antennas) utilize a series of antenna elements that allow the antenna bundle to be controlled electronically instead of mechanically. This allows signals to be emitted in or received from the correct direction. This is an important advantage for non-fixed systems such as aircraft and satellites. In addition, the radiation diagram can be adjusted so that the antenna sends or receives in one or more directions or that it receives more information or emits more energy in one specific direction than another. Because they are controlled electronically, beam-forming antennas are less vulnerable and do not require mechanical maintenance.