17 September 2022

R&D case: Augmented reality for maintenance training

Problem-based training with increased trainee activity

17 September 2022

Problem-based training with increased trainee activity

25 August 2022

As a passenger on an aircraft, the moment of landing is always full of emotions: the excitement as the objects on the ground start getting bigger and bigger; the runaway coming closer and closer; then -always a bit unexpectedly- the moment of touchdown. And let’s be honest a sigh of relief to be back on solid ground.

21 March 2022

NLR was the first to purchase a testing machine that helps to map the behaviour of material under specific loads much faster than was possible up to now. This enables NLR to draw up stricter design rules. Not only does this save on costs, but it also reduces resource consumption and thus waste while maintaining the desired quality.

14 February 2022

An important trend in the sustainment of aircraft engines is the transition from preventive maintenance to predictive maintenance. This concept aims to minimise the engine down-time and maintenance costs while preserving its required performance level and airworthiness. For this it is necessary that the momentary engine condition can be established and that this condition can be reliably extrapolated to a convenient moment in the future in order to facilitate the planning process.

11 February 2022

Chromate containing dust can be found in aircraft and aircraft components and engines. It may or may not be recognisable by its yellow colour. The presence of chromate containing dust poses a health risk for mechanics and other people coming into contact with it. Therefore the questions where it originates from and how to mitigate the risk for personnel need to be answered for safe operation and maintenance of the aircraft.

11 February 2022

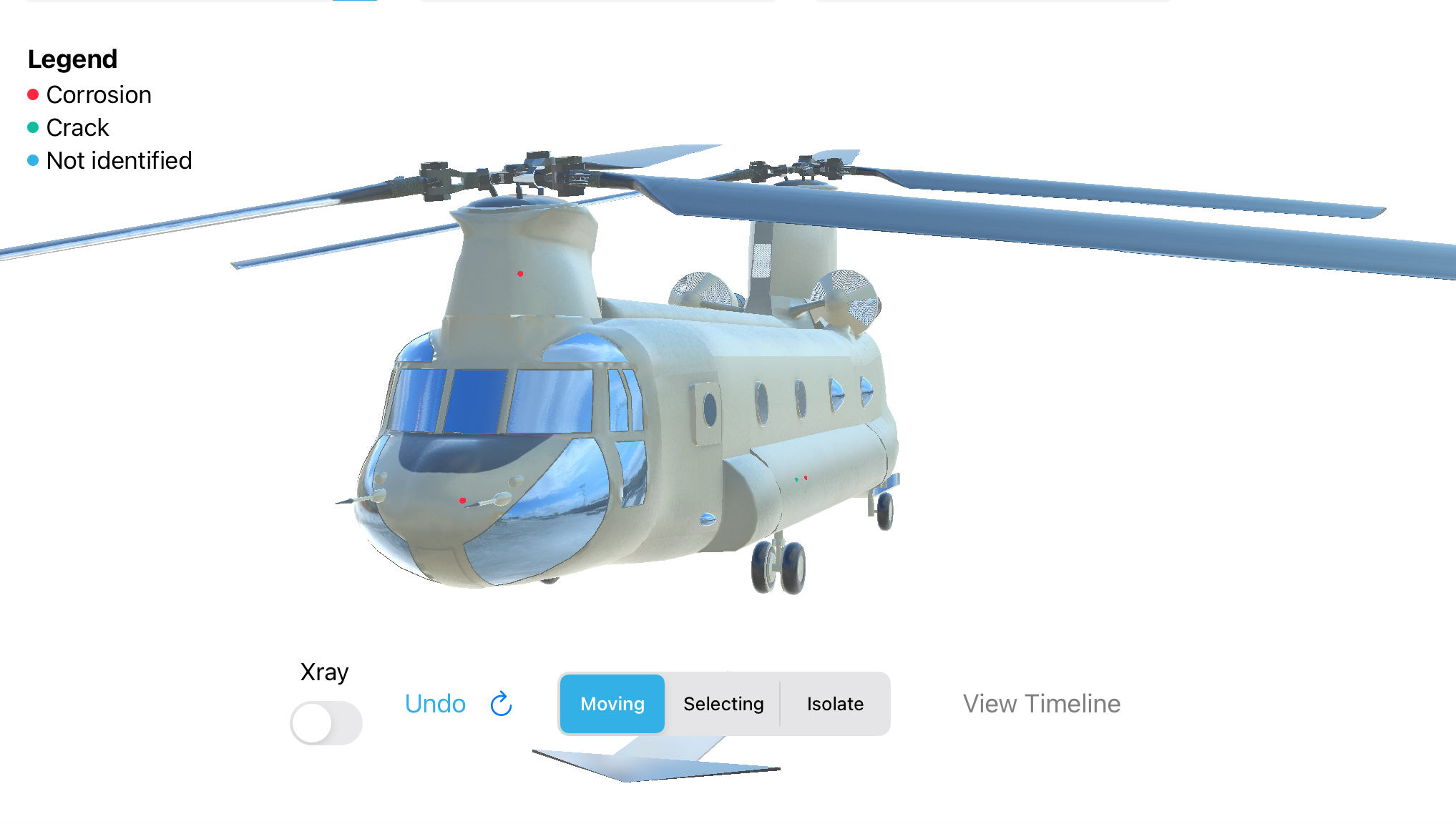

Digital crack and corrosion logbook. Reliability Centred Maintenance processes such as MSG-3 aim to decrease the maintenance burden, mitigate operating risks and deliver sustainable equipment reliability and readiness. For this, high fidelity inspection and maintenance records need to be available.

20 June 2019

19 June 2019, Amsterdam – KLM Engineering & Maintenance and Royal Netherlands Aerospace Centre (NLR) have launched a joint venture, NUVEON, for the development of new Augmented Reality (AR) products for MRO (maintenance, repair & overhaul). NUVEON will integrate AR throughout the MRO chain to improve everyday performance in maintenance. The new partnership was signed at the Paris Airshow by Olaf Hoftijzer, Director Training E&M KLM, and Marja Eijkman, Division Manager Aerospace Operations, Royal NLR.