26 June 2023

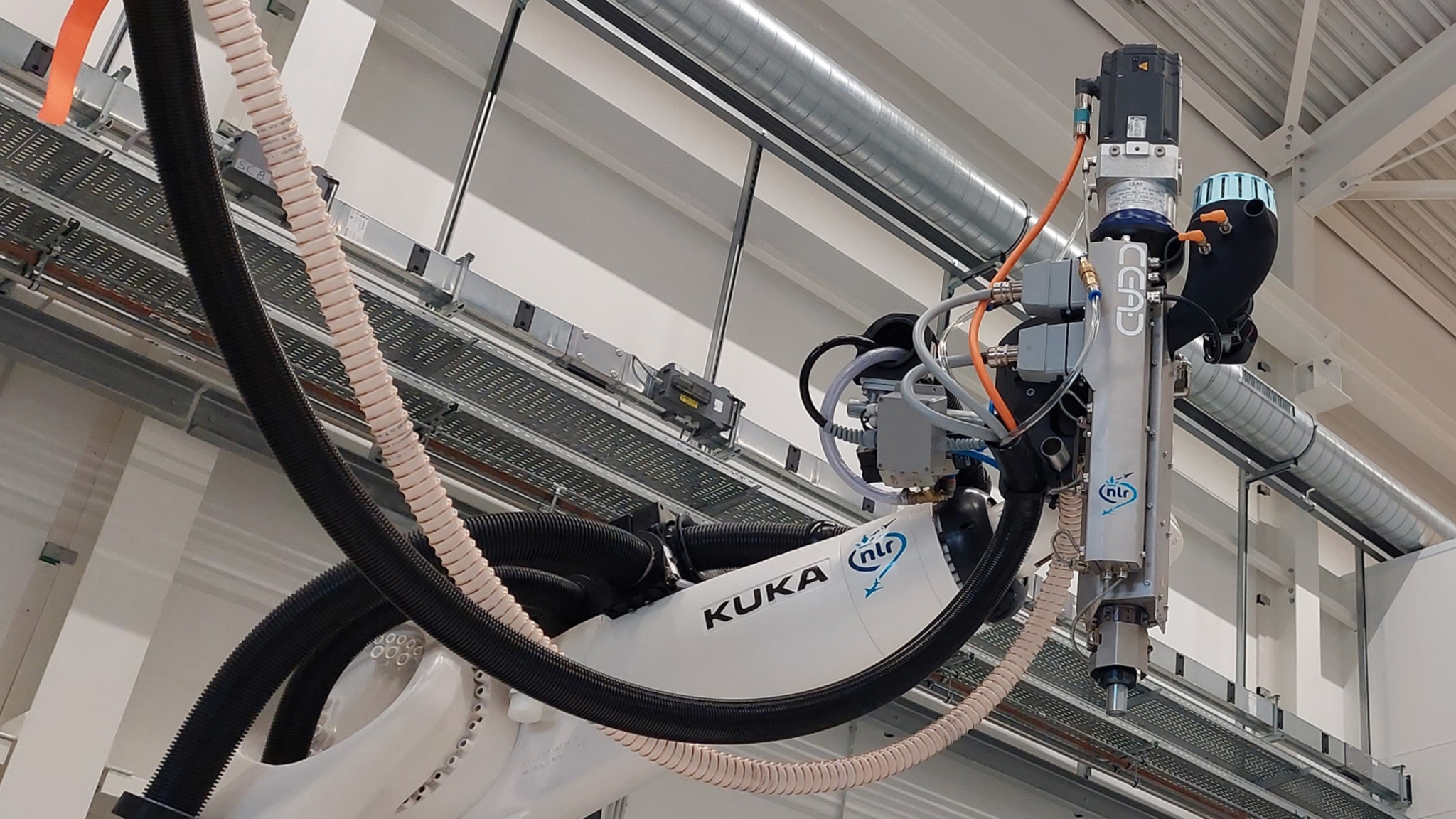

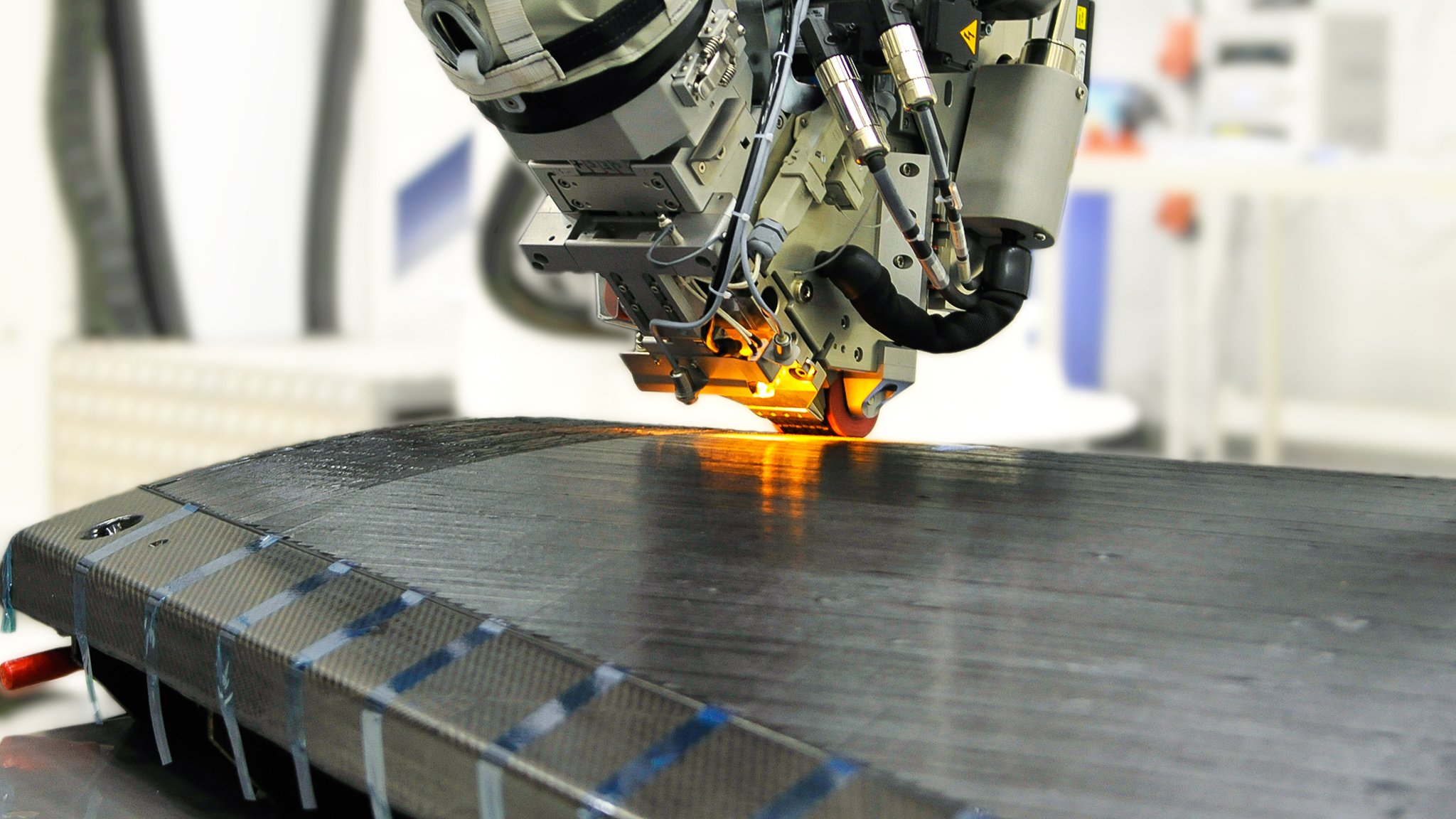

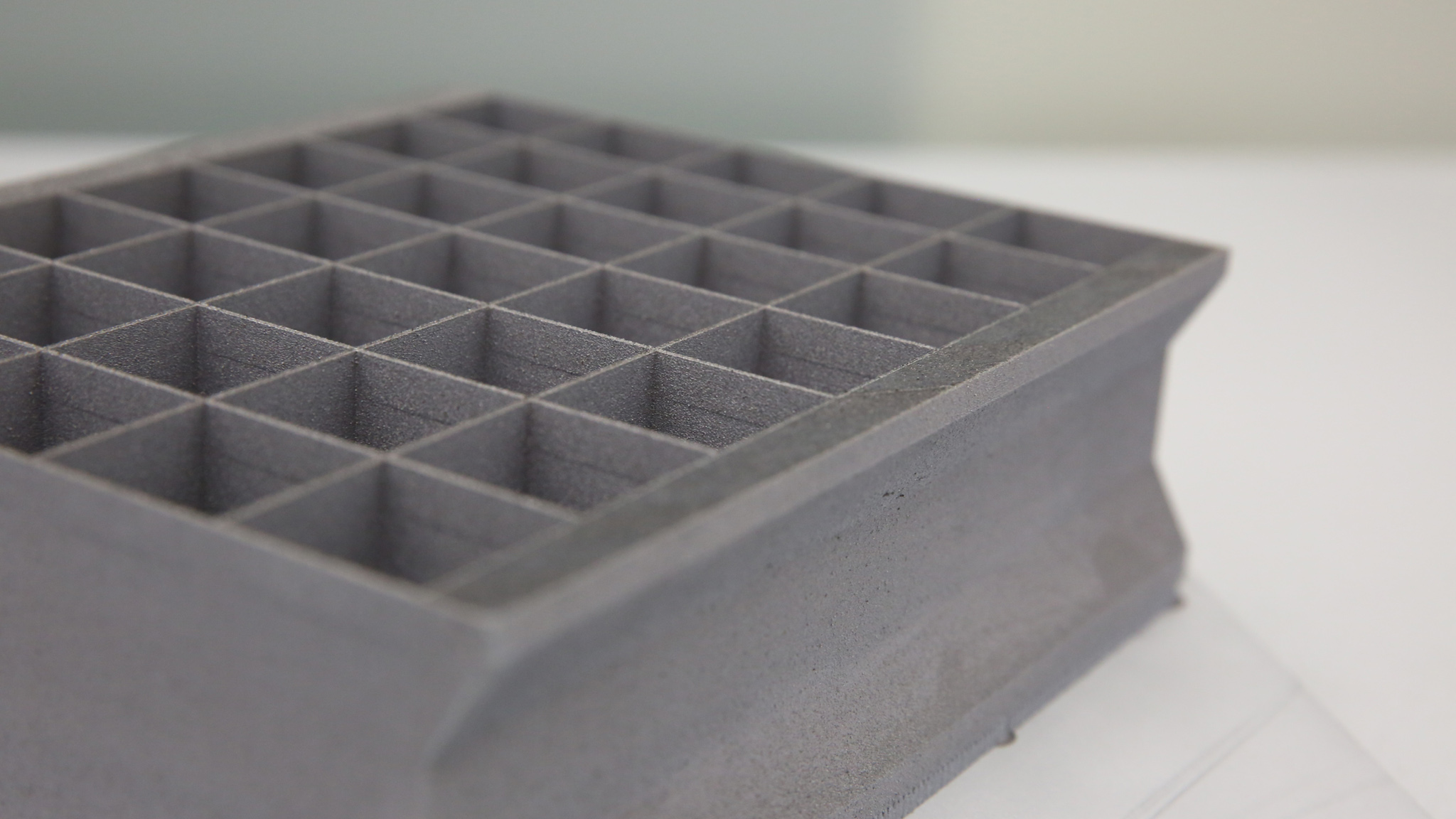

NLR and ECOMAT join forces in the field of innovative and sustainable aviation

During the Paris Air Show, the German ECOMAT and Royal Netherlands Aerospace Centre signed a Memorandum of Understanding. With this, the two parties want to combine their scientific and business expertise with regard to lightweight constructions, hydrogen developments, materials research and virtual product development in the aircraft manufacturing industry.