Unplanned downtime and costly repairs pose a significant challenge to helicopter operators, as they can compromise the operational efficiency and safety of flights. Predictive maintenance offers a solution by identifying and addressing potential issues before they become major problems, thereby reducing downtime and risks to crew and passengers whilst also lowering overall maintenance and repair costs. The more accurate loads can be monitored, the better the knowledge about the condition of the structures can be foreseen.

Real-time fiber optic sensing technology

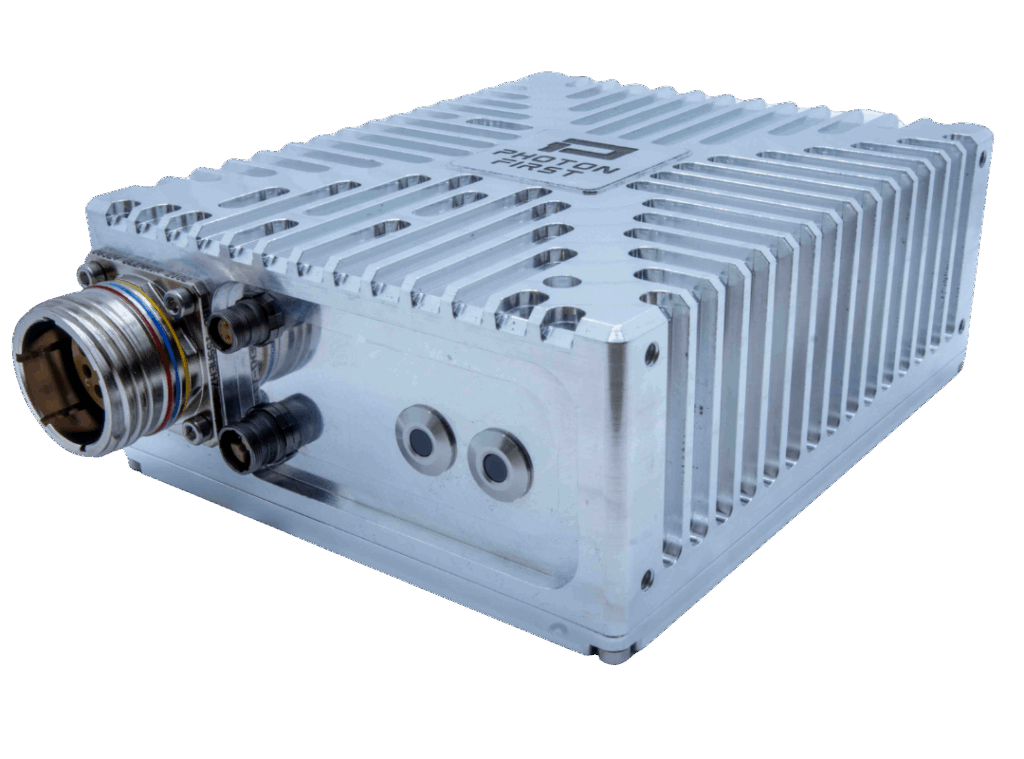

PhotonFirst will launch a new aerospace-certified fiber sensing interrogator at Paris Airshow, specifically designed for operation in extreme conditions. This sensing system, based on optical fiber sensors and integrated photonic chips, will be certified for usage on the NH90 helicopter in July. This certification represents a key milestone in the deployment of fiber optic sensing technology in aviation systems.

In close collaboration with PhotonFirst, NLR is further developing this technology into a fully integrated SHUMS solution, suitable for broad adoption in the helicopter market and beyond. By combining their expertise in sensing technology, airworthiness, and system analysis, the two organisations are setting a new standard for real-time monitoring of structural loads and fatigue during flight—a crucial enabler for predictive maintenance and operational readiness.

Tineke van der Veen, CEO of NLR: “ As an applied research centre we aim for practical solutions that make aviation safer and more efficient. Therefore we fully support this outstanding health monitoring solution as it provides the real-time condition of structures due to actual loads.”

Leendert-Jan Nijstad, CEO of PhotonFirst, adds: “Our collaboration with NLR is essential in translating our optical sensing solutions into certified applications for global aerospace OEMs. We are proud to be setting a new benchmark in structural health monitoring together.”