Research infrastructure

NLR’s research infrastructure comprises a diverse range of facilities and equipment, forming the foundation of our applied research. Our state-of-the-art facilities are accessible to companies and other research institutions, allowing for collaborative innovation. Explore our extensive facilities here and learn how they can support your project.

12 March 2025

Advanced Mechanical Manufacturing Facility

Our Advanced Mechanical Manufacturing Facility specialises in high-tech, high-spec lightweight structural concepts for wind tunnel models in metal, laminates, and composites. We offer a comprehensive range of services, including product design, topology optimisation, production concept assessment, and manufacturing of prototype structures, smart wind tunnel models, and small production runs. By utilising 3D printing technology (metal additive manufacturing), we can enhance product performance thanks to the freedom of design and the ability to create complex internal structures that minimise weight while maximising performance with advanced materials.

04 March 2025

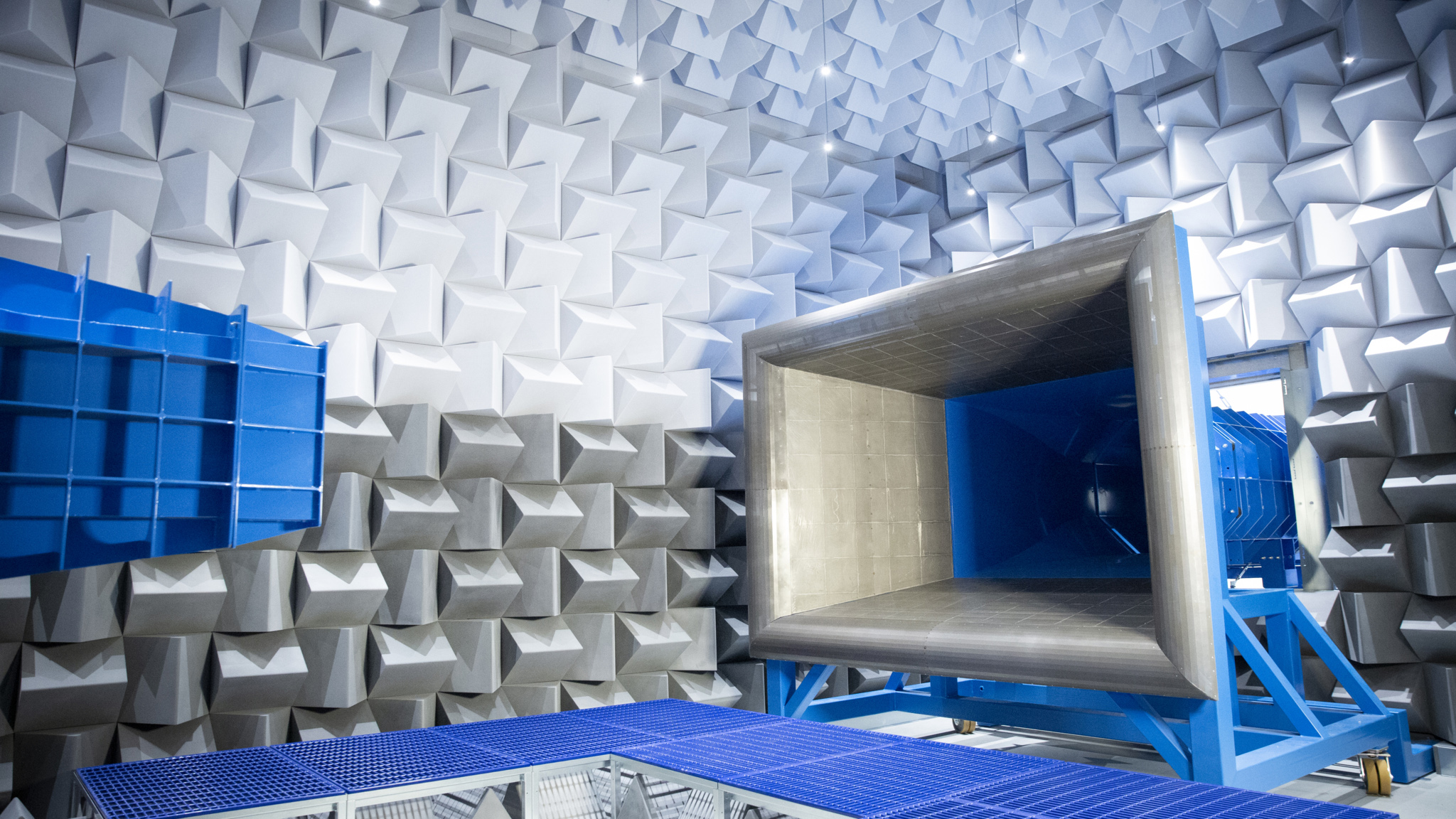

Aeroacoustic Wind Tunnel

The NLR Aeroacoustic Wind Tunnel (NLR-AWT) is a state-of-the-art facility dedicated to researching the sources of aero-acoustic noise and developing techniques to reduce aircraft noise. Our research focuses on the early development phase (low Technology Readiness Level) or aims to improve existing systems. Additionally, we develop advanced measurement methods to identify and quantify noise sources. To gain a deeper understanding of complex airflows, we employ various flow measurement techniques, including Particle Image Velocimetry (PIV) with helium-filled soap bubbles and hotwire measurements, which enable us to map airflow patterns both qualitatively and quantitatively.

04 March 2025

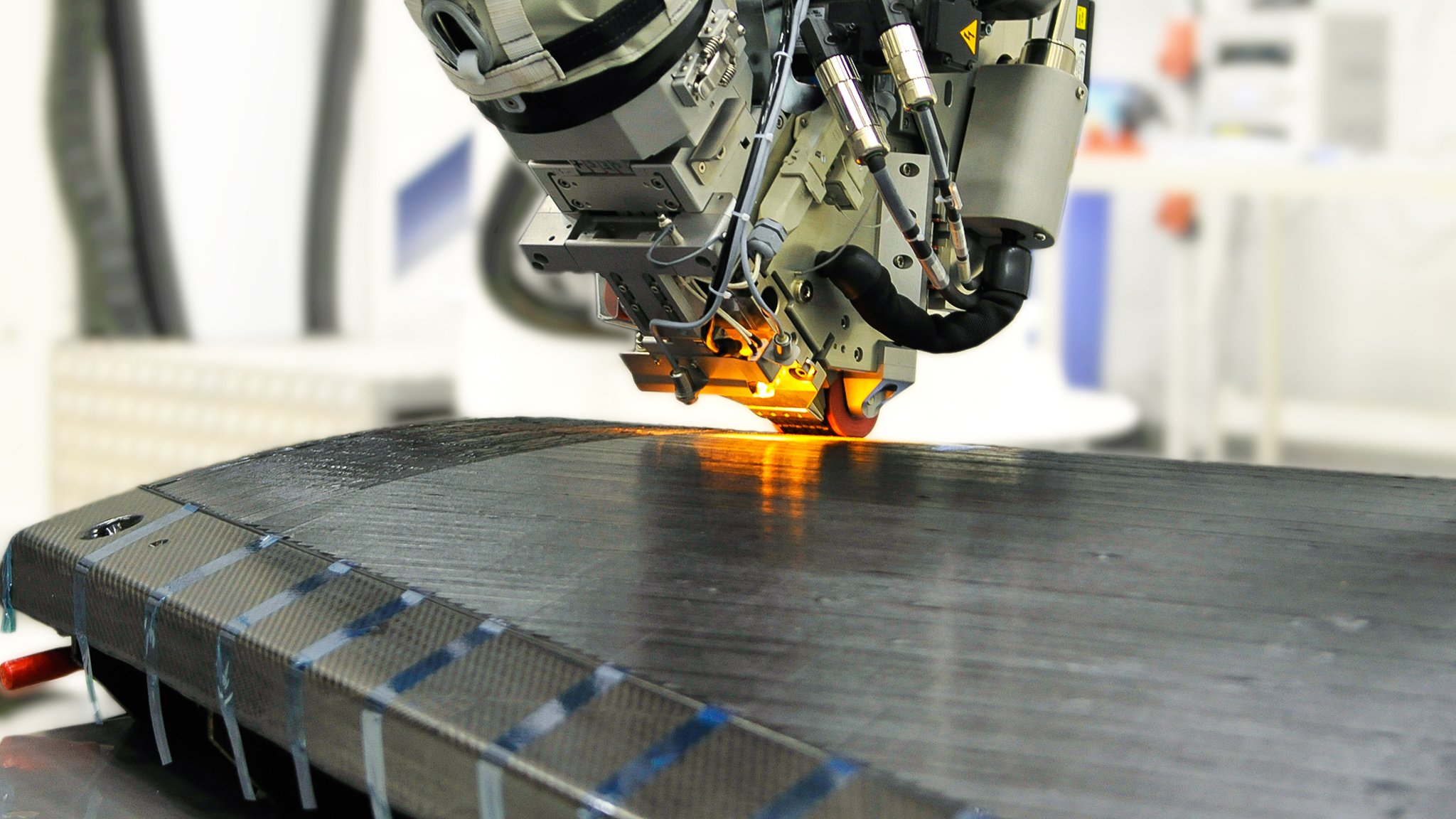

Automated Composites Manufacturing (ACM3)

The ACM3 Field lab (Automated Composites Manufacturing, Metal Manufacturing and Maintenance) is a world-class facility that offers high-tech equipment and expertise for the development of lightweight products. Its primary focus is on paving the way for automated manufacturing of advanced composite structures, with a strong emphasis on supporting the composites industry and companies that are looking to adopt these materials. By bringing together the collective research capabilities of leading research centres, universities, and specialised businesses, the facility creates a unique ecosystem that enables collaboration, innovation, and knowledge-sharing.is a well-equipped, state-of-the-art field facility that makes high-tech equipment available for the development of lightweight products. It serves to prepare the way towards automated manufacturing of advanced composite structures, largely in support of the ‘composites’ industry, but also of enterprises, which are new to this material. The facility brings together the complementary research capabilities of research centres, universities and specialised small enterprises and industries.

11 March 2025

Avionics Prototyping Environment (APERO)

The Avionics Prototyping Environment for Research and Operations (APERO) is a versatile and transportable research flight simulator designed to facilitate a range of applications, including avionics display design and evaluation, demonstration of innovative cockpit concepts, part-task training exercises, and networked flight simulation scenarios.

04 March 2025

Electro Magnetic Compatibility facility

Materials and equipment used in aerospace applications have to meet a wide range of special requirements, mainly due to the specific environment in which aircraft and spacecraft have to perform reliably and safely. NLR’s extensive capabilities and expertise in the field of airworthiness certification is complemented with state-of-art research infrastructure for aerospace systems performance and airworthiness compliance testing.

11 March 2025

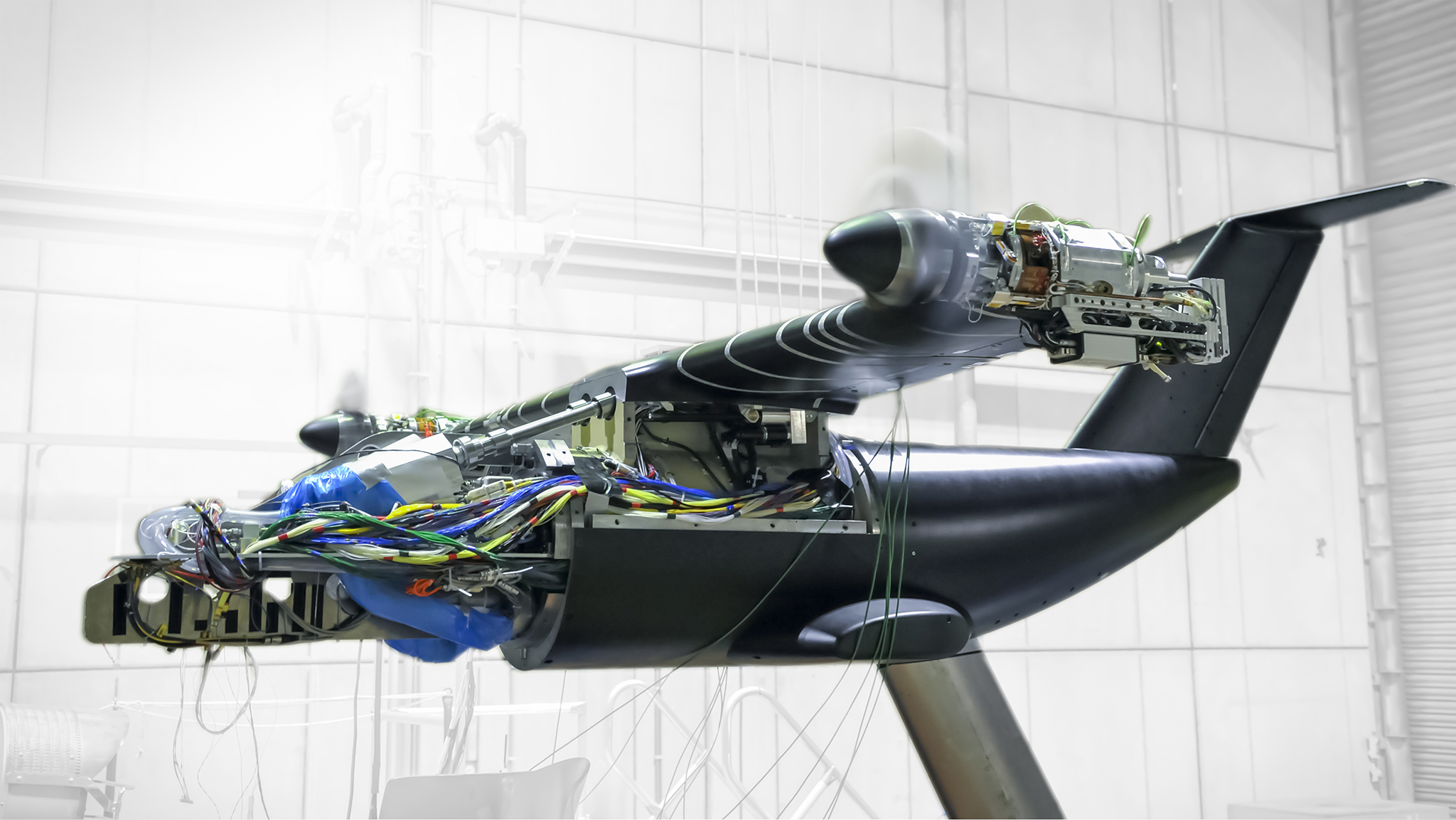

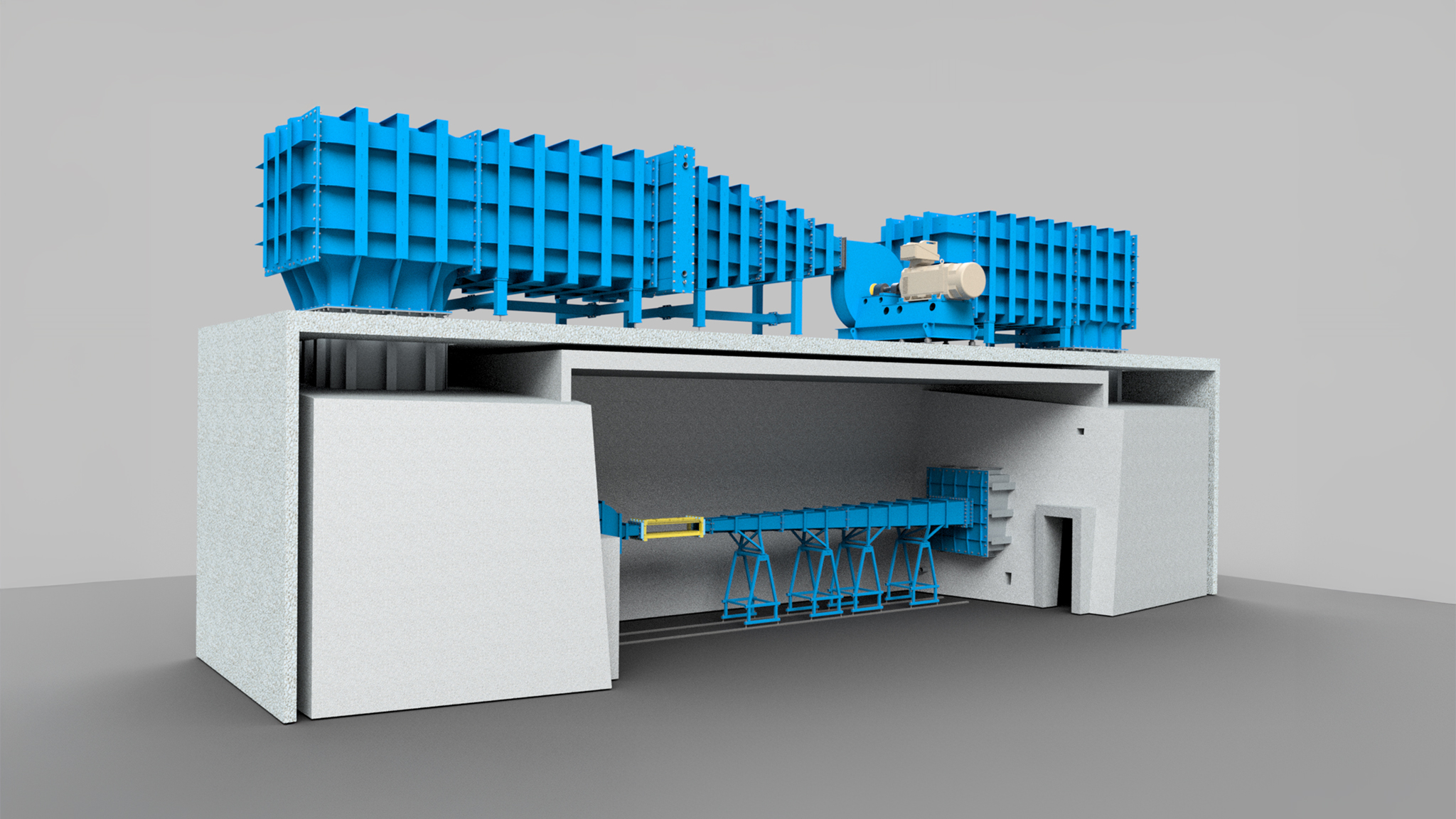

Flow Duct Facility

The Flow Duct Facility (NLR-FDF) contributes to research on noise reduction techniques to reduce aircraft noise. The research is carried out during the early development phase (low TRL) or to improve existing systems. The research is conducted during the early development phase (low TRL) or to improve existing systems. The FDF is a closed-loop wind tunnel for testing sound in turbine simulation at flow dimensions and speeds. Upstream and downstream of the test section, anechoic chambers are positioned to accurately measure sound levels.

11 March 2025

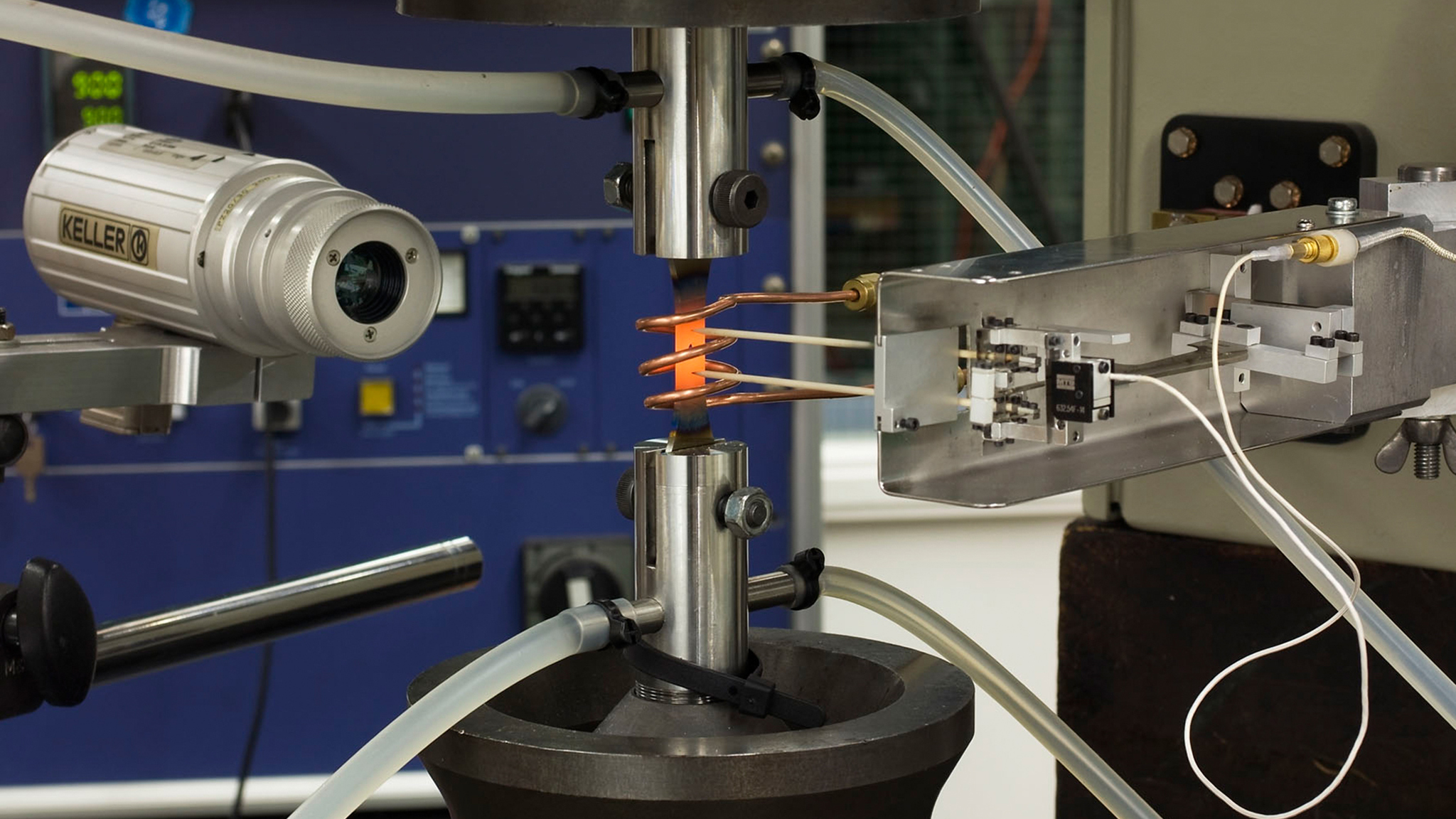

Metal Additive Manufacturing Centre

The NLR Metal Additive Manufacturing Technology Centre (MAMTeC) covers more than 50 years of materials experience in aerospace applications, technology development and product innovation. NLR can help you develop the process more efficiently, from optimised parameters, post-processing approaches, evaluation of mechanical properties, design optimisation and process simulation through to the qualification and certification of metal–additive manufacturing (AM) products.

11 March 2025

ATM real-time simulator (NARSIM)

NARSIM is a real-time, human in the loop (HITL) Air Traffic Control (ATC) simulator capable of simulating the full working environment and working conditions of air traffic controllers in detail. As such, it provides a platform for training, validation and conducting research in a controlled environment on all aspects of air traffic control and the air traffic controller. These facilities are used for research and development of new user-interfaces, user-interaction, ATC system support, new and revised concepts of operation and development & assessment of ATC training and its effectiveness.

11 March 2025

NLR Drone Centre

The NLR Drone Centre provides a dedicated environment for conducting (experimental) flight tests, evaluations, and demonstrations of Unmanned Aircraft Systems (UAS) and sensor applications, as well as facilitating UAS concept development. The NLR Drone Centre in Marknesse has its own restricted airspace with the necessary authorisations and exemptions to facilitate these activities. It offers developers, manufacturers and business users, both civil and military, the opportunity to carry out test flights needed to take advantage of the opportunities offered by UAS developments.

12 March 2025

Research aircraft: Cessna Citation II

NLR’s research aircraft are essential for testing new flight procedures and technologies. NLR operates two research aircraft: the Cessna Citation II and the electric Pipistrel Velis Electro.

12 March 2025

Research aircraft: Pipistrel Velis Electro

NLR’s research aircraft are essential for testing new flight procedures and technologies. NLR operates two research aircraft: the Cessna Citation II and the electric Pipistrel Velis Electro.

11 March 2025

Test House structures and materials

NLR acts as a one-stop-shop for “Non-Standard” testing and certification of aircraft parts, structures and materials. The Test House facilitates inspection, testing, characterisation and failure analysis. This can be done on material level, coupon level, component level or full-scale level.

04 March 2025

Thermal Vacuum facility

Materials and equipment used in aerospace applications have to meet a wide range of special requirements, mainly due to the specific environment in which aircraft and spacecraft have to perform reliably and safely. NLR’s extensive capabilities and expertise in the field of airworthiness certification is complemented with state-of-art research infrastructure for aerospace systems performance and airworthiness compliance testing.

04 March 2025

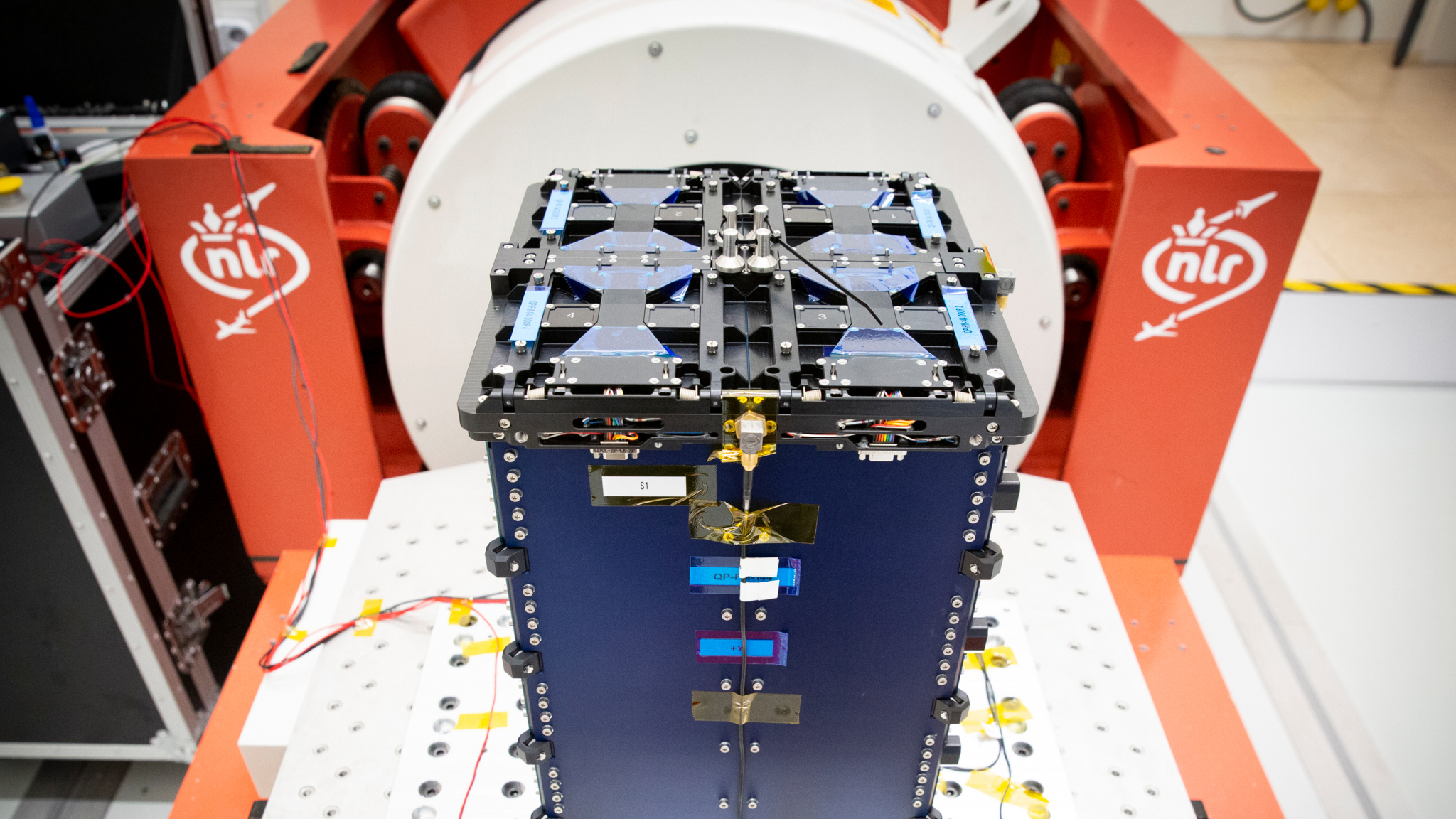

Vibration and Shock Test facility

Materials and equipment used in aerospace applications have to meet a wide range of special requirements, mainly due to the specific environment in which aircraft and spacecraft have to perform reliably and safely. NLR’s extensive capabilities and expertise in the field of airworthiness certification is complemented with state-of-art research infrastructure for aerospace systems performance and airworthiness compliance testing.