A maintenance-free, fast-rotating measuring system for a wind tunnel model capable of handling 8400 rpm. No such system existed yet, although it was required back in 2013 to conduct measurements with the wind tunnel model for the Z-08 Counter-Rotating Open Rotor (CROR), a next-generation concept for sustainable engines that can significantly reduce fuel consumption and CO2 emissions. To address this, NLR developed a highly advanced measuring system with a Contactless Rotating Power and Data Transfer (CRPDT) module, for which it has now been granted a patent. With the CRPDT module, NLR has cleared the way for ever higher rotational speeds, not only for wind tunnel models but also for airborne on-board applications.

Contactless rotating power and data transfer

Over the past ten years, there has been significant progress in the field of wireless data and power transfer, although the earliest developments within NLR date back to somewhere in the 60s”, according to Carlo Rens, R&D Engineer at the Electronics Development and Qualification department, which focuses on activities including electronics for data acquisition systems for wind tunnel models. The development of the wind tunnel model for the Z-08 CROR in 2013 was a defining moment in the development of rotating measuring systems within NLR. “We needed to fit a wind tunnel model with two engines with two counter rotating rotors with instrumentation as well as power and data transfer functionality”, says Rens. “This system would be rotating at speeds of over 8000 rpm, resulting in powerful centrifugal forces, which exert tremendous forces – up to 50,000 g – on the electronics and circuit boards. One of the important electronics components that can no longer be used at such speeds and under such forces is an internal clock, so a different solution had to be devised to address that.”

Carlo Rens and Peter Faasse from NLR

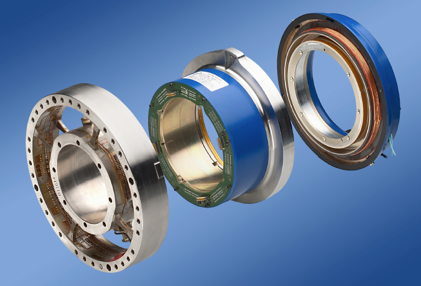

In traditional installations, slip rings are used, but these cannot be maintained at high speeds because they heat up too much and cause too much data interference. For that reason, NLR developed a new way of transferring power and data – one that does not require physical contact. “The system uses two rings, one transferring power and the other data”, explains Rens. “The power is transferred based on the principle of a transformer, and data transfers are effected using two coupled strip lines that work with local, intentional crosstalk.

‘Excellent performance’ label

The project with contactless power and data transfer has been operational for 750 hours over a 9-month test campaign of the Z-08. During that time, it was used in a number of measuring campaigns, by both DNW and Airbus, without any data being lost. “The system has proved to be very robust and we’re very proud of that. It’s been a lot of work, but it has paid off and that’s made it worth the headaches it gave us at times”, says Rens. The test results were reason for Airbus to give the CRPDT system its ‘excellent performance’ label.

Because this is a completely new system, NLR chose to apply for a patent on the high rotational speed contactless power and data transfer system. This will ensure the system’s wide-ranging applicability in the future, for instance for the licensed development of components containing the contactless system on anything that requires a rotating measuring system on a shaft, for commercial purposes. Currently, no systems with this capability are commercially available.

1 Gigabit per second

For the measuring system, the CRPDT had to be capable of handling 15 Watts of power and 100 Mbit/s of data. NLR’s rotating measuring system and the CRPDT were mounted on the rotating strain balance that was used to measure the loads on the blades of the Z-08 model. Thanks to the multidisciplinary environment within NLR it was possible to develop the module in-house in its entirety. Because the CRPDT system was so promising, Airbus requested a new test in 2015, this time with a 1 Gbit/s connection, which effectively made it an upgrade of the previous version

Contra-Rotating Open Rotor test system including rotating strain balance, data acquisition system and CRPDT module

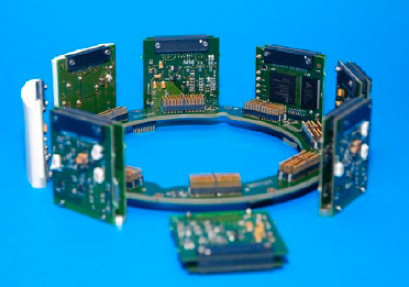

Rotor modules, arranged around a rotor backplane board.

High-end rotating propeller measuring system

Out of the wind tunnel, into the air

“In September, we started a new project – ‘Constance’ – in the context of the European Clean Sky 2 programme”, says Rens. “In this project, the CRPDT module will be applied in a real flying tiltrotor aircraft, the Next-Generation Civil Tiltrotor built by Leonardo Helicopters in Italy. The technology used for the CROR in the wind tunnel will be used in this project. The system will be part of the flight control system in the tiltrotor, making it a flight-critical system.”

The system will need to be capable of a data transfer rate of 100 Mbit/s and power transfer with maximum of 140 Watts. For the power module, NLR will be collaborating with their partner DDC in the UK. A feature that was not part of the wind tunnel installation will be an azimuth sensor to determine the angle of the rotor blades. The flapping sensors on the rotor make use of the azimuth sensor and are linked to the flight control system via the Constance. The traditional slip ring it used to be equipped with for data transfers will be replaced by the NLR’s contactless system.

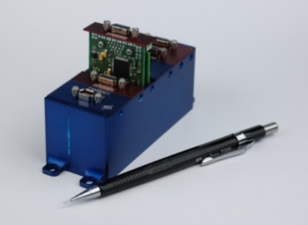

Mini measuring system

Sometimes, big measurements need to be performed on a small scale. In 2016, the Miniature Data Acquisition System (MiniDAQ) was a new milestone. For this module, it was important to allow for the future miniaturization of all required measuring systems. NLR managed to squeeze all the hardware used in the measuring systems of the Z-08 into a box measuring only 4x4x10 cm. Via a fibre-optic cable, the MiniDAQ enables data from 20 separately configurable channels to be read using only 4 Watts. “The big advantage is that only one fibre-optic cable and two power cables are required, instead of 80 wires for all rack strips”, says Rens.

Certification

Because the CRPDT system will be installed in an aircraft that will be actually airborne, there are a number of challenges to surmount, because in a flight-critical system, nothing can malfunction. “Errors caused by outside influences like lightning or dust must be ruled out”, says Rens. “Nonetheless, there is a big difference with the CROR wind tunnel model in that the rpm value will not exceed 700.” However, before the system can actually be used in an aircraft, it has to be made certifiable first. NLR has a long track record in certification procedures. Rens: “A major advantage of a certified component is that it opens many doors. This will make the module suitable for any application requiring a rotating measuring system.”

New possibilities

Rens is always looking for new areas of application, both within and beyond the aviation industry. Owing to the small scale of wind tunnel models, the rotation speed of rotors is far higher than for normal aircraft. In addition, the scale also requires everything to be very small and efficient in terms of execution. Considering that the future of professional aviation will likely see unmanned aircraft with RPAS becoming reality, NLR can look forward to an entirely new field of work.

Another application is monitoring rotor health and impact detection using fibre-optic Fiber Bragg Grating (FBG) sensors, which NLR is already researching in collaboration with Curtiss Wright, TFT and AcQ. And the list goes on: NLR is looking into possibilities to integrate contactless power and data transfer into composite structural aircraft elements, for which it entered into a partnership with Fokker Aerostructures and ELMO. This research is still in the early starting phase.

Its purpose is to develop CRPDT into a more standardized product. For wind tunnel models, the system has progressed to highest Technology Readiness Level TRL 9, but has yet to reach the stage of airworthy application. “We are working towards TLR 7 with a flight campaign of the tiltrotor”, says Rens. “Our aim is to get it to a stage where it is production-ready, possibly with a production partner”.

For further information please contact Carlo Rens

(US Pat. No. 9,812,255; CND Pat. No. 2,879,466)

Download your copy on ‘A Contactless Telemetry System for a Contra-Rotating Open Rotor Test Campaign’

Keep exploring

Need to know more? Visit our Augmented and Virtual Reality capability page.