Europe is aiming to make climate-neutral aviation possible by 2050. This demands new aircraft concepts. New propulsion methods will have to be developed, for instance, based on electricity, hydrogen and sustainable fuels. On top of that, new materials and innovative constructions could make aircraft more fuel-efficient in the future.

“Scale models are going to help aviation

take some big steps forward.”– Leo Timmermans NLR

The contemporary aviation industry uses a variety of analyses, simulations and wind tunnel tests when designing new types of aircraft. For taking technological development up to the next level, scale models – or Scaled Flight Demonstrators (SFDs) – can be a godsend. These are scaled-down, unmanned aircraft that are controlled from the ground. NLR is investigating the potential of this technique as part of Clean Aviation’s Large Passenger Aircraft Programme, a European programme aiming to develop clean aviation technologies in the shorter term.

Bridging the gap between research and practice

The idea is that scale models can bridge the gap between research and practice, explains Timmermans.

“When you’re designing a new aircraft, you do all kinds of calculations and tests in the wind tunnel. Then pretty soon you have to take the major step of developing the real model. The problem with that is that you can’t test the dynamic movements of an aircraft – banking and so forth – in a wind tunnel. So you’re never totally sure whether the aircraft will behave in practice as you initially calculated.” Testing with scale models can help understand dynamic movements, according to Timmermans. “It lets you minimise the risk of having to go back to the drawing board again.”

Ultimately, this saves time and costs and speeds up the certification process. This process can currently take many years because the flight behaviour of the new type of aircraft is not yet fully known.

Airbus A320

To investigate the use of scale models in aviation, NLR built a research aircraft in collaboration with Orange Aerospace: a scale model similar to the Airbus A320, an airliner mainly used for medium-haul flights. The scale model is about eight times smaller, with a wingspan of 4 metres, giving it a take-off weight of 140 kg and a cruising speed of 95 knots (175 km/h). During the investigation, the key question is how well the dynamic flight behaviour of the scale model corresponds to the real A320.

Mission flights in Italy

The SFD was first tested in DNW’s wind tunnel in Marknesse (NL), followed by the first flights in Dutch airspace, in Deelen in March. After successful completion of these qualification flights, the entire system was transported to Aeroporto di Taranto-Grottaglie in southern Italy to carry out measurement flights.

The Italian Aerospace Research Centre (CIRA) developed the Guidance, Navigation and Control (GNC) system that the scale model used for carrying out a total of 70 automated manoeuvres in Italy. The GNC is thus effectively a second autopilot on board the aircraft. The aircraft is camera-controlled and actually flown from a cockpit just like a real plane, but from the ground. The camera is attached to the tail of the SFD. A head-up display (HUD) developed by NLR is used for relaying information to the pilot. The GNC can be switched on from the ground station, after which it flies a pre-programmed route during which the manoeuvres are executed.

“We were aiming for the same level of accuracy

as for full-scale aircraft”– Floris Bremmers NLR

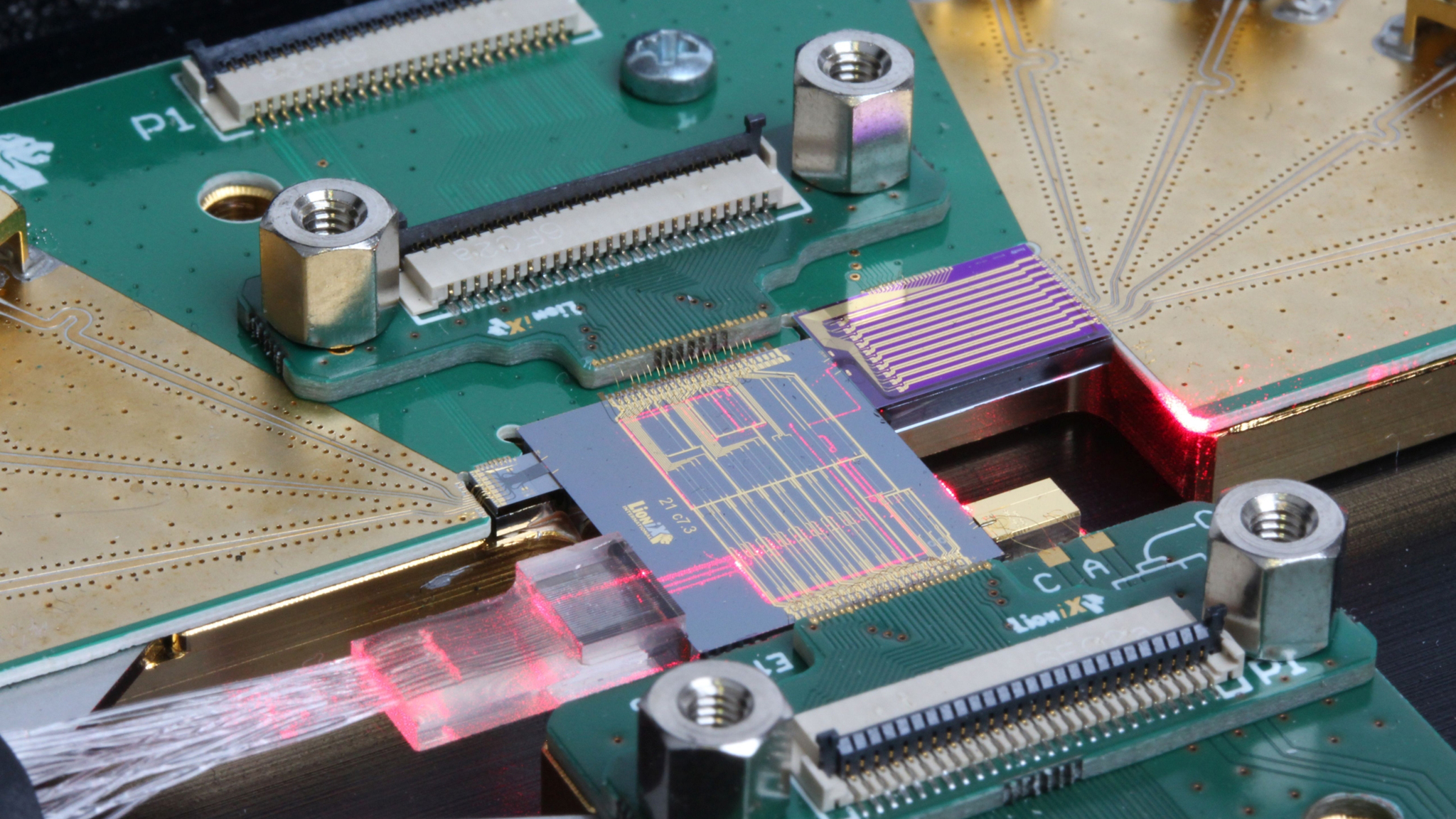

There was also advanced test equipment on board for measuring the aircraft’s flight characteristics, including small sensors for measuring the airspeed, aircraft movements and positions of the control surfaces. “Those measuring devices also had to be scaled down, of course,” says Floris Bremmers, an R&D engineer at NLR, “and we were aiming for the same level of accuracy as for full-scale aircraft.” Bremmers was involved in the project from the very start and was also present on site during the test flights. “We tested things such as how quickly the aircraft responds to input from the cockpit on the ground while performing various manoeuvres. We also carried out measurements of the dynamic flight behaviour, for instance as a result of manipulating the ailerons.”

Overcoming the challenges

Bremmers admits that it did not all go totally without a hitch. The team faced several challenges in Italy, such as having to replace the plane’s engine several times due to dirt on the runway. Switching from the autopilot to the GNC system did not go smoothly at first either. “I remember one incredibly tense moment when the autopilot took a turn during the switching process, tilting the SFD more than ninety degrees sideways and thirty degrees downwards. This ‘upset’, as they call it, happened at lightning speed – within one second. Our pilot immediately took control, from the autopilot. We then landed immediately, of course, and analysed what had gone wrong. It was a technical problem that we were able to resolve on the spot. Very challenging, but I’m proud that we managed.”

Over the next few months, the flight data analysis will be done, carried out by the French ONERA organisation and Airbus, comparing the dynamic behaviour of the SFD against the real A320. “The first results are already in, at any rate,” says Bremmers, “and they look positive.”

Now in the making: the electrically powered SFD

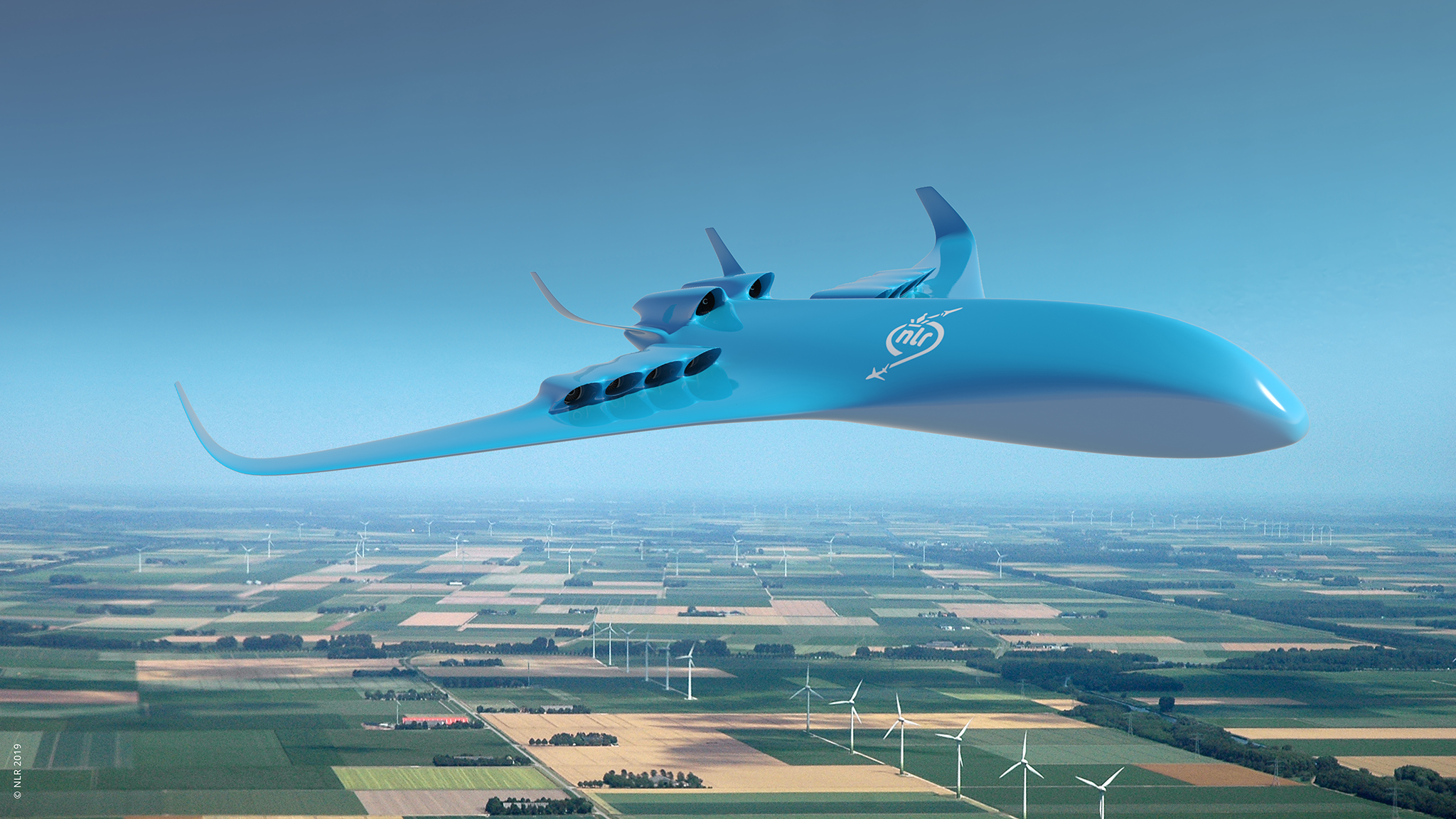

In the meantime, a lot of hard work is being done on a follow-up version of the SFD called the DEP-SFD (Distributed Electrical Propulsion SFD) in which the two jet engines, currently powered by fuel, are replaced by electrical propulsion using six propellers. This is a direct test of the use of scale models when producing radically new aircraft designs.

“We need to do more research about the characteristics of electrical propulsion,” explains Timmermans. “That will let us design more fuel-efficient aircraft in the future. The flight characteristics of that kind of aircraft are different; testing them at scale will let us incorporate those features into the design in the best possible way.”

Additional information:

Read more about the SFD at our NLR website: https://www.nlr.org/sfd or learn more about related demonstrators here.

Test flights of the DEP-SFD are expected to be carried out in 2023. “We’re looking forward to the final results of the SFD,” concludes Timmermans. He has great expectations and the situation is urgent. “Scale models are going to help aviation take some big steps forward.”

Project partners:

The SFD is developed by a partnership of Airbus, NLR, ONERA, and CIRA, with support of Orange Aerospace.

This development has received funding from the Clean Sky 2 Joint Undertaking (JU) under the European Union’s Horizon 2020 research and innovation programme under grant agreements No 717183 and 945583.