Digital crack and corrosion logbook. Reliability Centred Maintenance processes such as MSG-3 aim to decrease the maintenance burden, mitigate operating risks and deliver sustainable equipment reliability and readiness. For this, high fidelity inspection and maintenance records need to be available.

The challenge

The data entry portal of the current generation of maintenance data systems is cumbersome and non-intuitive. Most of the data has to be entered manually and the likelihood of entering inconsistent and/or incomplete data is high. The quality of the recorded inspection and maintenance records therefore is often less than satisfactory. This negatively affects the ability to conduct useful reliability analyses.

The solution

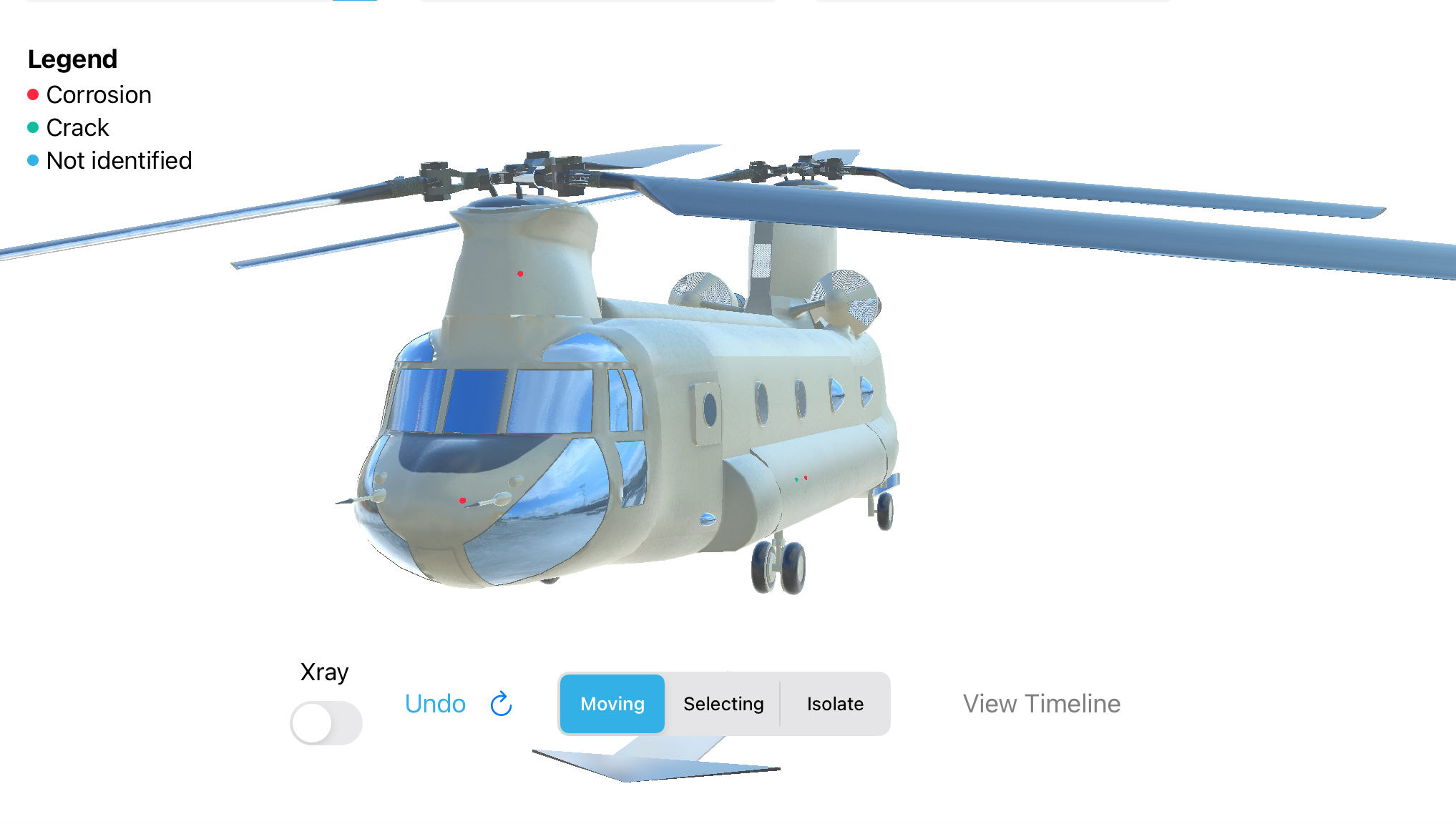

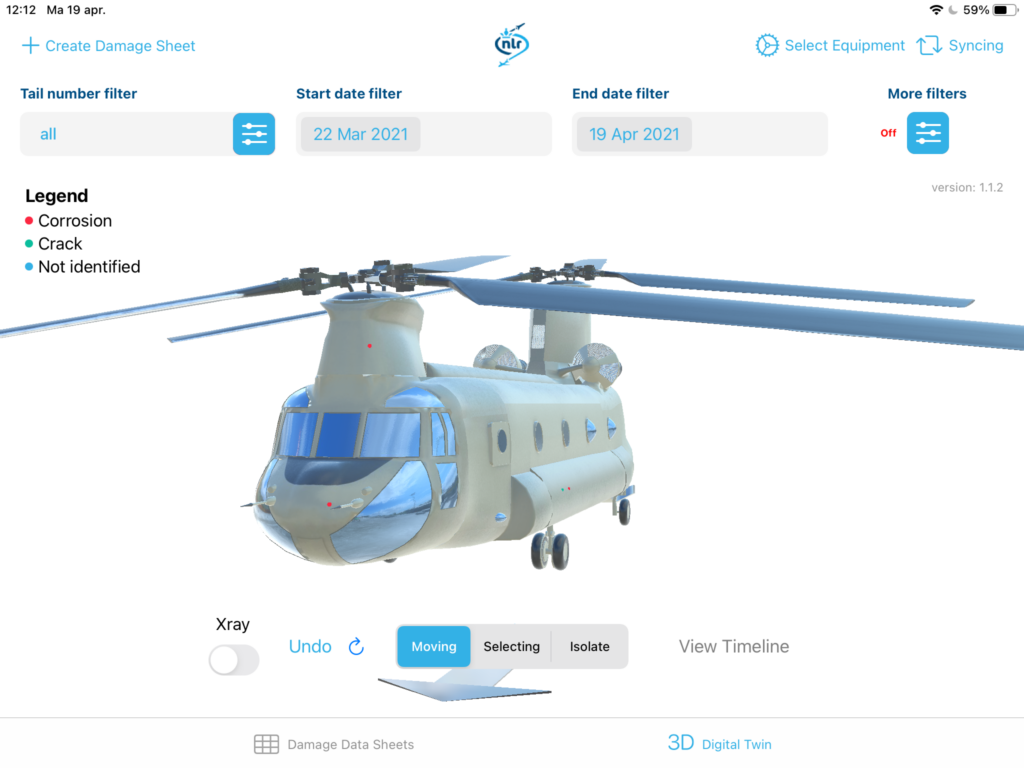

To improve the consistency and completeness of structural inspection findings, and to reduce the administrative burden on maintenance personnel, Royal NLR developed an intuitive and easy-to-use interface, the digital Crack & Corrosion Logbook (d-CCL) that takes away the data entry burden for the maintenance engineers.

What did we do?

The d-CCL is an app that runs on a tablet computer and features an intuitive 3D web interface. The inspection findings can be entered either graphically, through a 3D model of the aircraft at hand, or by means of pull-down menus. The app connects to a server as soon as an internet connection is available, upon which data synchronization is performed with the ERP system of the aircraft operator.

Historical data and data from other aircraft in the fleet are thus readily available to the maintainers. This enhances their situational awareness and increases the probability of detecting structural anomalies.The app is complemented with centralised software for performing fleetwide reliability analyses.

Project partners:

Royal NLR and Royal Netherlands Air Force