Only by reshaping the methods for aircraft structural design currently used for aeronautical structures, the full potential of the innovative propulsive solutions, such as electric or hydrogen flying, will be unleashed and aviation will be on its way to be fully sustainable.

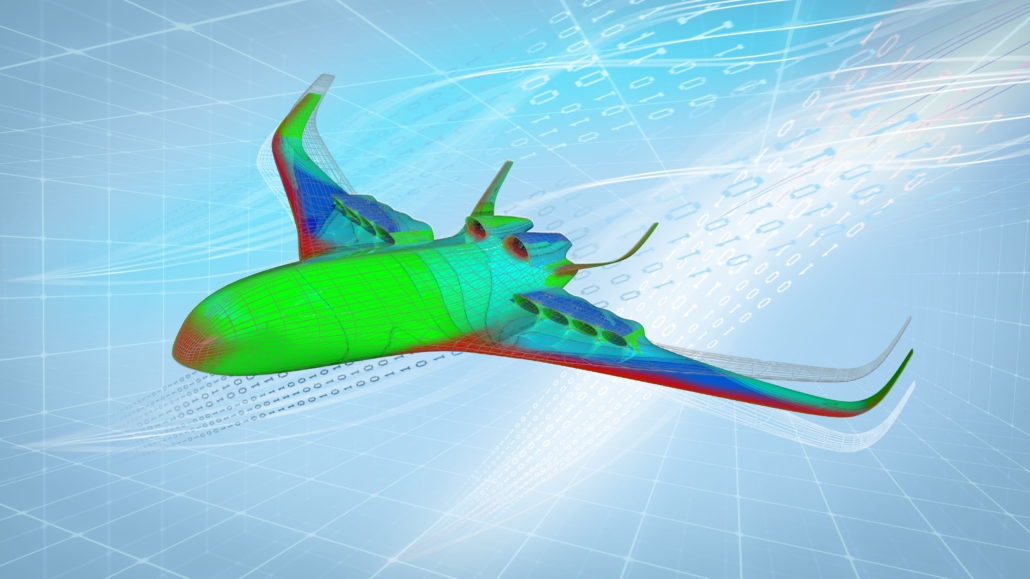

Tackling the consequences of climate change and avoiding the impact of resource scarcity necessitate a circular economy and a continuous decrease of the environmental footprint of human activities. Within the aviation sector, those goals have initiated a transition to zero-emission propulsion concepts, based on electric batteries or hydrogen as energy source. Incorporating those new types of propulsion in an aircraft have an impact on the design of the vehicle itself. The design of the future aircraft is moving beyond the traditional cylindrical fuselage and wing, towards blended wings or flying-V concepts. In order to make aviation sustainable down to the smallest structural element, the current design methods and calculation models used need to be rethought, together with the related certification practices.

Emiel Amsterdam, senior R&D engineer within the Structural Integrity department at NLR, summarises the status of current design practices and models and the needs for the future design and certification approaches in the white paper: ‘Aircraft structural design in the future’.

Amsterdam: “To incorporate circular design approaches aiming at keeping aircraft in use as long as possible, such as reparability, reusability, recyclability, is not only beneficial for the environment, but it will reduce operational costs and energy consumption. Nonetheless to truly achieve this, there is the need for a clean-sheet holistic structural design and integrity approach. This white paper highlights our views on potential developments and implementation of materials, technology and methods that are necessary.”

As heard more often aircraft design methods may need a bit of dusting off. The majority of the verified methods in aircraft design have been developed by the fast expanding aerospace industry during the 1960’s and 1970’s. At that time, great developments in engineering were achieved with limited aid of computer calculations, simulations and data storage. Nowadays, the limitations in computer power and data storage are nearly gone and computer simulations are used in many aspects of the aircraft design approach. Yet, many better, more comprehensive methods and models are still not integrated in the overall design and optimization approach. Until now there has been no urge to challenge the design methods, as developments in materials and engines delivered very high improvements in fuel consumption and weight; on top of this, changing methods may even challenge the safety levels achieved by airframe structures, if not researched correctly. But right now implementing new methods may reduce the level of conservatism still embedded in airframe structures, delivering additional improvements in weight saving, and also enabling to keep the aircraft in service longer by considering maintenance and repair aspects of aircraft components.

One field which has so far received little attention in terms of innovation is structural integrity, fatigue and damage tolerance. Those aspects are usually considered at the end of the design approach with the available legacy methods. Those are mainly empirical equations describing, for example relationships between the nucleation and growth of fatigue cracks and the stresses experienced by the aircraft structural materials.

As these equations generally lack a physical basis, our understanding and current predictive capabilities of fatigue crack growth and life time analysis are limited, Amsterdam explains.

This inevitably leads to conservatism in the design, the necessity to perform expensive full scale fatigue tests and, occasionally, unexpected fatigue crack findings and early need of repair. To further optimize the structural elements of the aircraft, while maintaining structural integrity and the highest level of safety, there is the need to rethink the design approach and incorporate new models and methods developed in the last decades.

“The white paper contains the ambitions of NLR experts”, states Amsterdam. “But we are aware that to achieve the goal of a new sustainable design, collaboration is of extreme importance. With the Horizon Europe and Clean Aviation programs starting soon, NLR hopes to identify partners willing to pick up the challenge“.

If you want to know more about the white paper, or if you want to participate in Horizon Europe or Clean Aviation projects, please reach out to Emiel Amsterdam: emiel.amsterdam@nlr.nl.

The white paper is to be downloaded here: whitepaper Aircraft structural design

For additional information also take a look at our website: https://www.nlr.org/capabilities/structural-integrity/

Royal NLR

Royal NLR

NLR/TU Delft

NLR/TU Delft