A new programme recently kicked-off that aims to help Dutch SMEs and industry manufacture certified 3D metal printing products. Six companies are already participating in the programme and it is expected that this number will double. The programme’s total budget is 5.5 million euros.

A new programme recently kicked-off that aims to help Dutch SMEs and industry manufacture certified 3D metal printing products. Six companies are already participating in the programme and it is expected that this number will double. The programme’s total budget is 5.5 million euros.

This Public-Private Partnership programme, set up by the TO2 institutes NLR and TNO, will run for four years. This so-called ‘Metal Additive Manufacturing’ programme was established with the assistance of the Ministry of Economic Affairs and fits within the Top Sector HTSM.

The programme is a textbook example of collaboration within the ‘golden triangle’ of government, institutes and industry. In addition to EZ, NLR and TNO, six other companies are currently participating in the programme, including one SME. Dutch universities are also involved, with the programme offering three PhD positions.

Why 3D printing?

The great design freedom, possibilities for integrating functions, and high material efficiency offer great opportunities for 3D metal printing in demanding applications, such as Aerospace and High-End industry. Weight reduction and improved functionality provide additional value to these applications. The main limitation for large-scale 3D printing applications is the lack of available methods for certifying 3D metal printing processes.

Several large aerospace companies with self-certification-authority are currently developing methods for the qualification of their 3D printed products. However, it is much more difficult for smaller companies to do this alone.

NLR and TNO have set up this PPS programme for Dutch industry, in order to establish the necessary foundation whereby metal products with multiple applications can be manufactured at a competitive price and with a consistent print quality.

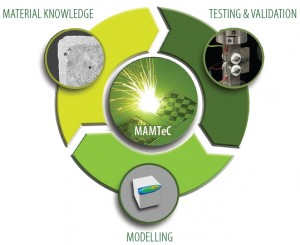

Specialist areas covered by the programme include: material knowledge, processing knowledge, certification & qualification, and design methods. In addition, participating companies are given the opportunity to include a technology demonstrator.

The PPPs are currently being drafted and signed. There are however still openings for industry and SMEs to participate. To take part in the programme, industry annually contributes €50K (or €30K and €20K, in kind), SME’s €25K for a ‘Premium membership’ (which includes the possibility of introducing a demonstrator and participating in the Programme Board), or €15K in order to receive access to all technical findings. NLR and TNO each contribute €200K annually.

Interested parties should contact:

NLR-Marknesse

Metal Additive Manufacturing Technology Centre

Marc de Smit

e: MAMTeC@nlr.nl

t: 088-5114234