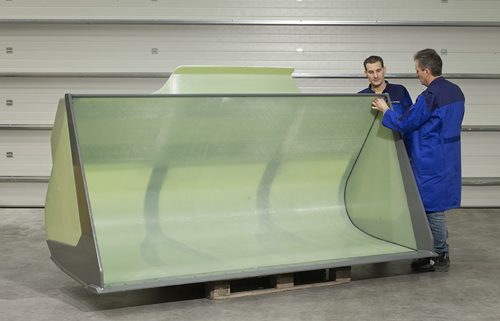

The lightweight bucket for heavy construction work

Consortium wins prestigious innovation award

A consortium led by NLR has won the JEC innovation Award 2015 for its composite front-loader bucket. The bucket was especially deemed a successful innovation owing to its increased capacity and weight reduction.

The JEC Innovation Awards are presented annually at the JEC Europe Exhibition, the largest professional exhibition of composite materials in Europe. The consortium won the award in the ‘Heavy Machinery’ category for its application of composites in creating a hybrid solution. The winning consortium consists of NLR, VABO Composites, ICO, Kuiken and Gurit. By joining the different disciplines from the parties involved, the project was a success.

The application of composites is primarily reserved for high-tech sectors, such as the aerospace industry, which the reason why NLR has developed extensive expertise in this area. However, now that production technologies and raw materials are better understood, alternative applications have emerged. The Institute for Composite Development (Instituut voor Composiet Ontwikkeling (ICO)) therefore asked NLR to replace a steel front-loader bucket with a composite prototype. This request came from Compoworld, an initiative of various stakeholders within the composites sector in Netherlands, including the national government.

In 2014, tests conducted with the prototype revealed that a bucket made of such composite materials could indeed offer major economic benefits. First, by using stress gauges, researchers determined how much force was exerted on the bucket during heavy construction work, a process that involved pushing the steel bucket against a concrete obstacle, which caused the front-loaders’ large wheels to spin.

NLR was then able to convert this data into a series of requirements that composites must meet in order to produce a comparable bucket from composite material. This process also involved a determination of the material characteristics (such as resistance to abrasion and elasticity), as well as the economic considerations pertaining to the production costs. Consequently, a choice had to be made about the most economic methods for aggregating the fibres and resin, the two primary components of all composites.

Under the guidance of NLR, two different prototype buckets were produced: one prototype was built at NLR in Marknesse, and the other at VABO in Emmeloord. Tests with the new bucket revealed that the composite buckets could move greater volumes of dirt and sand than was possible with a conventional steel bucket. The users of front-loader composite buckets could therefore complete the same amount of work using fewer bucket loads than was possible with a front-loader equipped with a steel bucket. Moreover, the achieved weight reduction (up to 35 percent of the bucket’s net weight) also resulted in lower fuel consumption. Later this year production of this hybrid bucket-loader will commence at VABO Composites.

Award

The award ceremony will be held on Tuesday, 10 March 2015 in Paris during the JEC Europe Exhibition, a major international composites exhibition. The bucket-loader can be viewed in the Showcase Area, hall 7.2, stand C78. Other innovations in the field of composites can be viewed at the general NLR stand in hall 7.3, stand F3. The exhibition will be held in Pavilion 7, at Porte de Versailles. We are pleased to invite you to join us at the awards ceremony on Tuesday, 10 March, starting at 17:00.