Global aviation growth has averaged 5.5% year-on-year for the past ten years according to IATA, and the growth is expected to continue in the coming decades. How can the environmental impact for people living around airports in the Netherlands and other European countries be mitigated as much as possible? As part of the EU’s Horizon 2020 programme, research is underway to answer this cross-border question. One of the elements of the research programme is the NIPSE project (Novel Integration of Powerplant System Equipment). The purpose of the project is to drive the development of a new generation of aircraft engines that are more efficient and thus consume less fuel and cause fewer harmful emissions. The engines are expected to come on to the market in 2025. The most important research results were recently presented at the ILA Air Show in Berlin.

Global aviation growth has averaged 5.5% year-on-year for the past ten years according to IATA, and the growth is expected to continue in the coming decades. How can the environmental impact for people living around airports in the Netherlands and other European countries be mitigated as much as possible? As part of the EU’s Horizon 2020 programme, research is underway to answer this cross-border question. One of the elements of the research programme is the NIPSE project (Novel Integration of Powerplant System Equipment). The purpose of the project is to drive the development of a new generation of aircraft engines that are more efficient and thus consume less fuel and cause fewer harmful emissions. The engines are expected to come on to the market in 2025. The most important research results were recently presented at the ILA Air Show in Berlin.

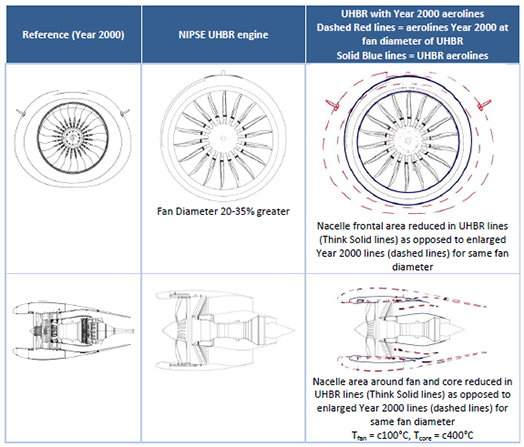

Within the NIPSE project, NLR has made significant contributions in several areas that are important to the development of these UHBR engines (Ultra-High Bypass Ratio). With their larger fans, these engines are larger than conventional engines. This makes it important to keep the ‘nacelle’ as streamlined as possible to avoid increasing the drag of the aircraft and pushing up fuel consumption. This necessitates the more compact, lighter and better integration of all equipment associated with the engine, such as ducts, pipes, harnesses and electrical components. But how can you install these pieces of equipment as close as possible to each other? To better deal with this challenge, NLR developed an optimisation method and a software tool called NEAT (Next generation engine Equipment Allocation Tool). European engine manufacturers deployed and tested this method to optimally integrate the equipment in the nacelle. This saves them time and money in the design process and increases their competitiveness.

The challenge facing the Systems integration within the IPPS

As UHBR engines operate at slightly higher temperatures, NLR also conducted research for testing of ‘heat exchangers’, enabling the better cooling of the equipment. The heat exchangers were tested and validated at NLR in its Flow Duct Facility. NLR also played a role in testing, analysing and evaluating more compact, ‘flat’ cable harnesses and studied ways of improving test methods for determining the electromagnetic shielding of cables.

NLR fulfilled an essential role in the NIPSE project because of its multidisciplinary knowledge of such matters as system optimisation and thermal and electric modelling and analysis, in combination with its exceptional research facilities.

See also NIPSE-website

This research was funded from the EU’s Horizon 2020 Research and Innovation Programme under Grant Agreement No. 640597. But the views expressed in this press release are not necessarily those of the European Commission.

This research was funded from the EU’s Horizon 2020 Research and Innovation Programme under Grant Agreement No. 640597. But the views expressed in this press release are not necessarily those of the European Commission.