Project: BRAVA (Breakthrough fuel cell technologies for aviation)

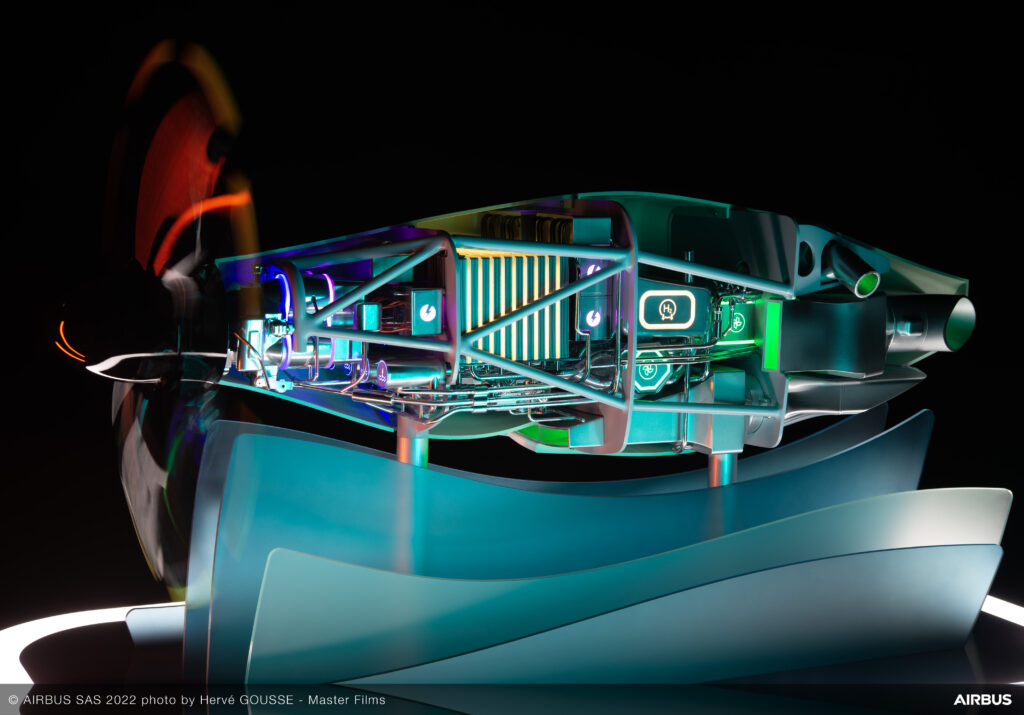

The BRAVA project focuses on innovative heat management for fuel cell-based power generation systems (PGS) for aircraft in order to address the mass and freezing limitations of conventional cooling systems. This will contribute to bringing flying on hydrogen a significant step closer.

The challenge

Conventional cooling systems employ a liquid (typically a glycolwater mixture) that is circulated by a pump to cool the fuel cells. However, this traditional approach results in a system mass that is too high for aircraft applications. Furthermore, the liquid is susceptible to freezing under cold conditions, which poses an additional challenge. To address these challenges, the BRAVA project has developed a novel two-phase cooling system, where the term ‘two-phase’ refers to the phase transition of the fluid from liquid to vapour.

The solution

The mass of the cooling system and the required pump power can be substantially reduced by leveraging the heat of evaporation of a liquid. In a two-phase cooling system, a pump circulates a fluid that evaporates in the fuel cells while absorbing the waste heat. Consequently, the required fluid flow is significantly smaller than in conventional liquid cooling, resulting in a much smaller pump and narrower pipe diameters. Detailed analyses by Airbus and NLR show that the mass of a 100-passenger aircraft with four engines can be reduced with approximately 1000 kg when a two-phase pumped cooling system is used instead of a conventional liquid glycolwater cooling system.

What did we do?

To investigate the feasibility of the two-phase cooling concept, NLR first built a test setup with a 20 kW cooling capacity. The test results were subsequently used to design and build a demonstrator for a two-phase cooling system with a 240 kW cooling capacity.

In these setups, electric heaters were used to emulate the heat load of a fuel cell. Additionally, a 5 kW two-phase cooling system has been successfully tested with a functioning fuel cell stack at Aerostack to validate the concept.

Project partners:

Aerostack GmbH, Airbus Operations GmbH, Airbus Operations SL, CNRS, Heraeus Deutschalnd GmbH, Liebherr Aerospace Toulouse SAS, Madit Metal SL, Morpheus Designs SL, SYENSQO, Technische Universitat Berlin

Project timeline:

2023-2025

This project has received funding from the Clean Hydrogen Partnership under GA nr. 101101409