The aerospace industry is witnessing unprecedented growth, driven by increasing demand for air travel, advancements in space exploration and the need for more fuel-efficient and environmentally sustainable aircraft. In an industry where safety, performance and reliability are essential, the manufacturing processes play a critical role in achieving excellence. The development and production of aerospace moulds such as composites cure tooling is critical for ensuring the accuracy and reliability of aircraft components. Moreover, as the demand for more advanced, lightweight and geometrically intricate aerospace components grows, the industry requires tooling manufacturing equipment and techniques that can evolve and meet these needs.

Transformative shift

Aerospace tooling has traditionally relied on conventional materials and manufacturing techniques such as CNC machining of metals and layup of fibre-reinforced composites that often entail time-consuming processes and high costs, and impose limitations on design complexity. Now, with the advent of Large-Scale Additive Manufacturing (LSAM), the various industries are witnessing a transformative shift in tooling manufacturing processes, as it offers opportunities to revolutionise the production of tooling.

LSAM, also referred to as FGF (Fused Granulate Fabrication) or BAAM (Big Area Additive Manufacturing), has revolutionised the industry by facilitating the creation of intricate structures on a much larger scale than ever before. Additionally, reduced lead times and material consumption are important advantages of this additive manufacturing process, as it allows near net shape fabrication with little material waste.

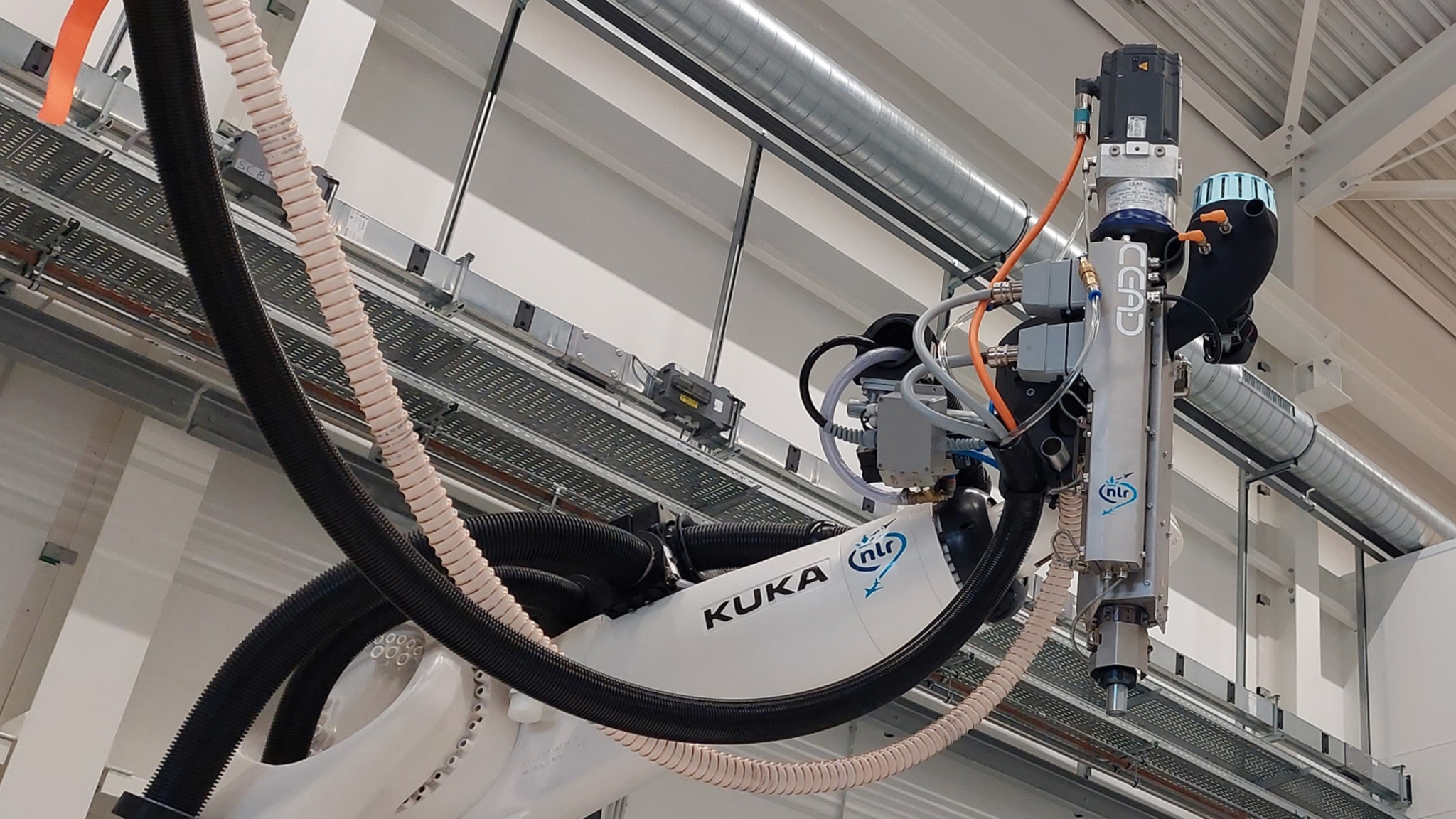

In this process, the raw material initially in the form of granules or pellets, is fed into a heated extruder, where it melts in several stages or heating zones. The molten material is subsequently deposited, layer by layer, to create the desired object. The extruder is typically mounted on a robotic arm or a gantry system that performs the movements to achieve the final 3D shape.

NXTGEN: LSAM equipment upgrades

Since its LSAM setup acquisition in January 2023, NLR actively participates in various projects dedicated to exploring this technology. In May 2023, a pioneering venture called NXTGEN E – Microfactory for e-mobility was launched with NLR taking part as a partner. Over the next four years, NLR will explore LSAM equipment upgrades that will be used to enhance production efficiency and reliability of high performance thermoplastics. To achieve its goals, NLR collaborates with esteemed partners such as CEAD, LEAM and Airtech.

CEAD is a Dutch technology company that is changing the game in large-scale 3D printing. NLR works with one of their machines and continuously collaborates with CEAD to further integrate LSAM technology in the aerospace industry.

LEAM is a spin-out of the Technical University of Munich, whose founders developed a technology that uses light to heat the material to enable Additive Manufacturing for the most challenging applications. NLR will be part of the pilot project acquiring and testing one of the first DEMEX devices (Directed Energy Material Extrusion), serving as substrate pre-heating equipment.

Airtech is a material provider with nearly 50 years of extrusion experience, now also adds value to Large Scale Additive Manufacturing with its Dahltram® Tooling Resins the need for lower CTE and a more robust service life when used at low or high temperatures, including use in an autoclave. NLR works with the Dahltram I-350CF material from Airtech, which is suitable for high temperature applications (212°C) and it’s been proven to withstand more than 500 heat cycles without significant degradation.

For more information,

please visit www.nxtgenhightech.nl.

For additional information about Additive Manufacturing check out this link, and you can download the whitepaper here for free to learn more about the complexities, challenges, and potential of the LSAM process: NLR Whitepaper LSAM.

This project is made possible in part by a contribution from the National Growth Fund programme NXTGEN HIGHTECH. This programme will invest as much as € 1 billion until 2030 with over 330 partners, in more than 60 projects and in six essential domains. In doing so, NXTGEN HIGHTECH will make a significant contribution to the structural and sustainable economic growth in the Netherlands and offer solutions for the major societal challenges in the areas of energy transition, health, safety and food.