- Advice on complex mechanical and multi-physics analyses problems for aerospace including advanced analyses with progressive damage prediction and post-buckling

- Advice on design and optimization for thermoset and thermoplastic composites aircraft structures

- Design and topology optimization of (additive manufacturing) metal structures

- Preparation for manufacturing using curing/distortion analyses and additive manufacturing residual stress calculation

- Virtual testing and virtual manufacturing

- Thermo-mechanical stress analysis and life prediction

- Fatigue analysis of components

- Experience in virtual manufacturing and virtual testing on coupon and component level, virtual full-scale testing, failure analysis of composite and hybrid structures with quasi static and dynamic loading (impact), post-buckling analysis of light-weight panels and structures, using modern finite element software (e.g. ABAQUS).

- Experience in metal additive manufacturing (L_PBF, DED) distortion and thermal predictions, investigation of aircraft and rotorcraft vibration, and topology optimization of aircraft parts

- Tools developed for aircraft panel analyses and optimization for fibre steering, composite damage prediction and failure analysis using user subroutines (UMAT, VUMAT), integration of parametric designs using plug-ins in ABAQUS

- Experience with and tools for predicting temperatures and stresses in thermally loaded components in e.g. gas turbines. We also perform life prediction for such components looking at strength, creep, low and high cycle fatigue. We can do this for a range of material including titanium and nickel alloys

- Experience with and tools for fatigue analysis for both safe life/crack initiation as-well-as damage tolerance/crack growth methods. For crack initiation we can perform finite element stress analysis and use methods to predict the fatigue life of components. For crack propagation we can apply automated crack propagation using XFEM, crack tip elements and perform crack growth analysis using NASGRO and in house crack propagation codes

- Collaborate with NLR’s experts in manufacturing, testing and non-destructive inspection to verify and validate our solutions, cooperate with NLR’s materials scientists to understand the response of materials and structures under normal and extreme loading conditions, work together with industry in European Projects such as MAAXIMUS, STUNNING, ALFA. This results in lead-time reduction and a more cost-efficient execution of aircraft design, modification and maintenance projects.

Documents

- Structures Testing and Evaluation Facilities Catalog

- Biaxial Testing

- Composite damage simulation for prediction of residual strength

- Curved Fuselage Panel Testing Facility

- Mechanical Test Laboratory

- Micro-mechanical test facility

- MOSAIC: Automated transfer of simulation models

- Optical 3D Deformation Analysis

- Impact Damage Tolerance of Thick Composite Structures

- Advanced Laminar Flow Tailplane

Video Clips

Related Issues

- Buckling calculations

- Composite design

- Composite fatigue analysis

- Computational mechanics

- fe-safe

- Fibre steered composites simulation

- Full-scale virtual test

- Global simulations

- High Cycle Fatigue (HCF)

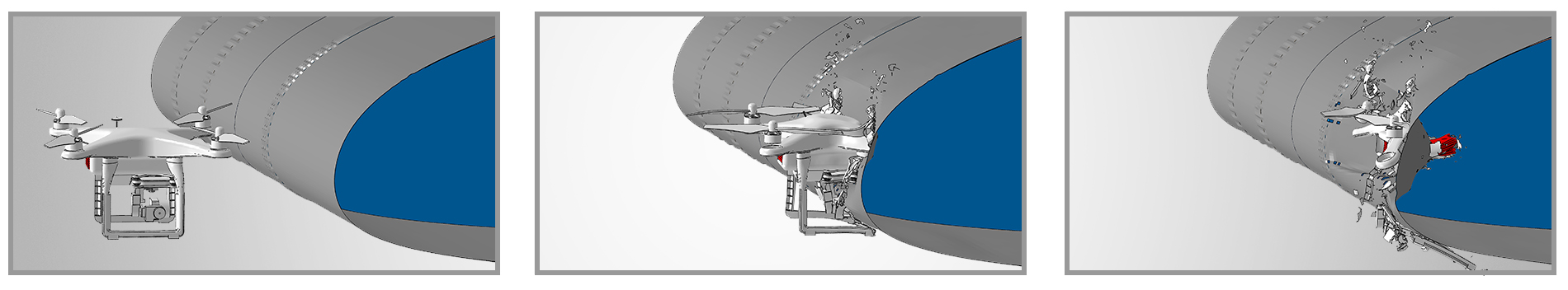

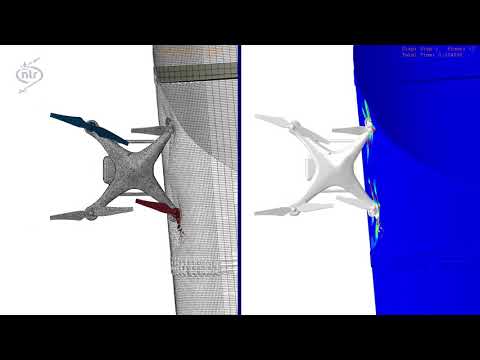

- Impact analysis

- Local simulations

- Low Cycle Fatigue (LCF)

- NASGRO

- Numerical analysis

- Post-buckling calculations

- Progressive damage analysis of composites

- Residual stress analysis

- Thermo-mechanical analysis

- Topology optimisation

- Variable stiffness laminate design

- Virtual testing