Globally, annual losses due to fatigue of metal components and structures are estimated at billions of euros. New fundamental insights into fatigue behaviour – where metals fail under low but cyclic loads – can help develop materials that are more resistant to fatigue. More accurate prediction of fatigue will for instance extend aircraft service lives or allow more lightweight designs, both of which help use energy and resources more sustainably.

Paris Law

The equation used for current crack growth theories for metals was introduced by Paul Paris in the 1960s and is also known as the Paris Law. This law is still used worldwide in the designs of aircraft, ships, bridges and buildings, for example. However, many corrections have been added to the law since the 1960s as it was found to be inadequate in many cases. Especially for cyclic loads with variable amplitude, which can occur in aircraft due to turbulence or in bridges due to different types of vehicles using them, the current theory gives poor predictions for the service life of metal structures.

To get better predictions of the service lifetime, NLR has conducted novel research in a public-private partnership called PROF (PRediction Of Fatigue in engineering alloys). The project was started in 2016 together with GKN Fokker, Airbus, Embraer, Wärtsilä, Lloyd’s Register, Delft University of Technology and the Royal Netherlands Air Force, aiming to develop a better physical model. Emiel Amsterdam, a senior scientist in the Aerospace Vehicle Structural Integrity & Life Cycle Support department, is project leader of the PROF project and first author of the article published on the subject in Engineering Fracture Mechanics.

Newton and Einstein

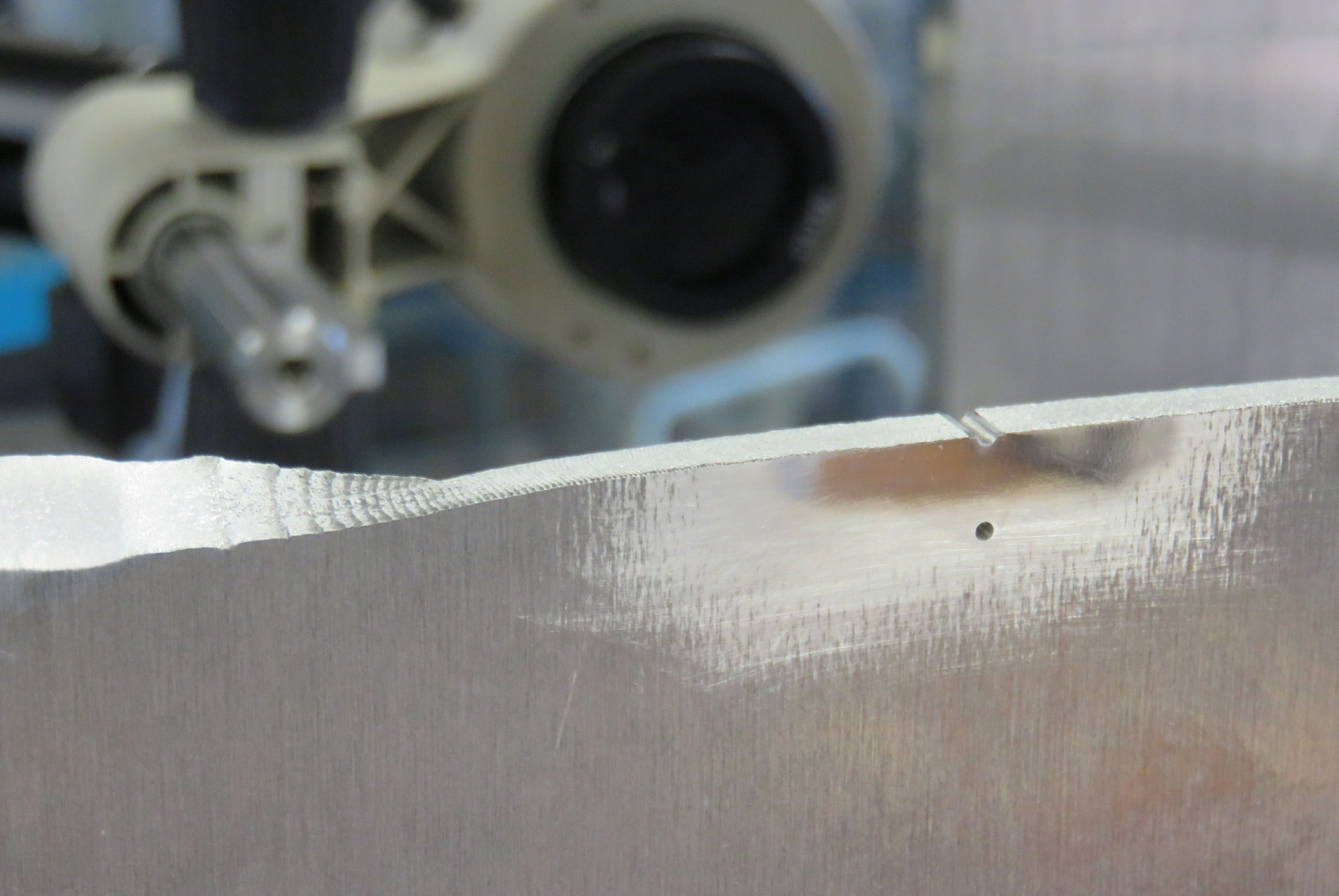

For the new theory on the fatigue crack growth rate in metals, Amsterdam went back to the basics of fracture mechanics, which were set out for cracks in glass in the 1920s. That predicts brittle fracture of glass based on elastic strain energy (in that case involving a high crack propagation rate and almost no plastic deformation). The current paper presents evidence for a new equation for ductile metals that uses two parameters, namely the elastic strain energy and the magnitude of the plastic strain field that is present in metals just in front of the tip of the crack. This contrasts with Paris’ Law, which only uses the elastic strain field around the crack. The new equation is more universal and simplifies to the Paris Law in some special cases.

“It’s similar to Newton’s second law, F=m∙a,” explains Amsterdam. “That law is fine in many cases, but in special situations – when the velocities are very high – you need Einstein’s special theory of relativity. But at low speeds, Einstein’s equation simplifies to Newton’s second law.”

Challenge

Better lifespan predictions can then be made by looking at how much elastic strain energy there is in a spectrum of variable amplitude load.

“We showed that the new theory works at an international challenge where you had to predict the lifespan of aluminium test specimens,” says Amsterdam. “For the challenge, parties from throughout the world gave blind predictions based on a given spectrum of variable amplitude loads. Our theory gave the best prediction and so we won the challenge, although the other parties had been fine-tuning their methods for years.”

Safer

“As a follow-up, predictions were also made for the US Air Force based on a load spectrum applicable to them. There too, the predictions nicely matched the results of the tests that were carried out by an independent third party.”

The new theory should eventually lead not only to longer and more sustainable use of metal structures but also to improved safety thanks to better predictions of fatigue crack growth, making catastrophic failure less likely.

The article ‘On the strain energy release rate and fatigue crack growth rate in metallic alloys’ in Engineering Fracture Mechanics can be read online for free until 26 June 2023 via this link: https://authors.elsevier.com/a/1h2Wo38l3hjM7.

Interested in more? Please visit our structural integrity page for additional information.