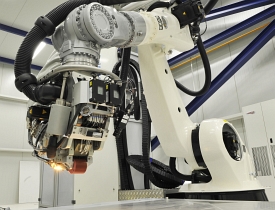

Today the National Aerospace Laboratory (NLR) officially began using its new Fibre Placement Machine. This machine allows large composite parts to be manufactured more quickly and at lower costs.

Today the National Aerospace Laboratory (NLR) officially began using its new Fibre Placement Machine. This machine allows large composite parts to be manufactured more quickly and at lower costs.

Composites play an increasing important role in aviation. Hence, there is now a new generation of commercial aircraft largely constructed of composite materials. These artificial materials are lighter and stronger than the traditional materials, like aluminium, used in aircraft manufacturing.

The development of new composites and their manufacturing technologies are now being fully developed. In this area, NLR has built a reputation based on comprehensive relevant research. NLR has now purchased a new Fibre Placement Machine that allows for the automated manufacturing of complex structures made of fibre-reinforced plastic.

Michel Peters, executive director of NLR: ‘This new machine is capable of the automated manufacturing of large products in shorter periods of time, which lowers production costs. We can therefore offer our stakeholders increased productivity and customer-focused operations. With this new investment, NLR once again bolsters the Dutch government’s policy of increasing corporate competitiveness.Â

Composites are not only applied in aviation, but also in the transport industry, maritime shipping sector, sports and aerospace engineering. NLR for example also develops composite structures for launch pads.