Construction and Manufacturing

15 December 2025

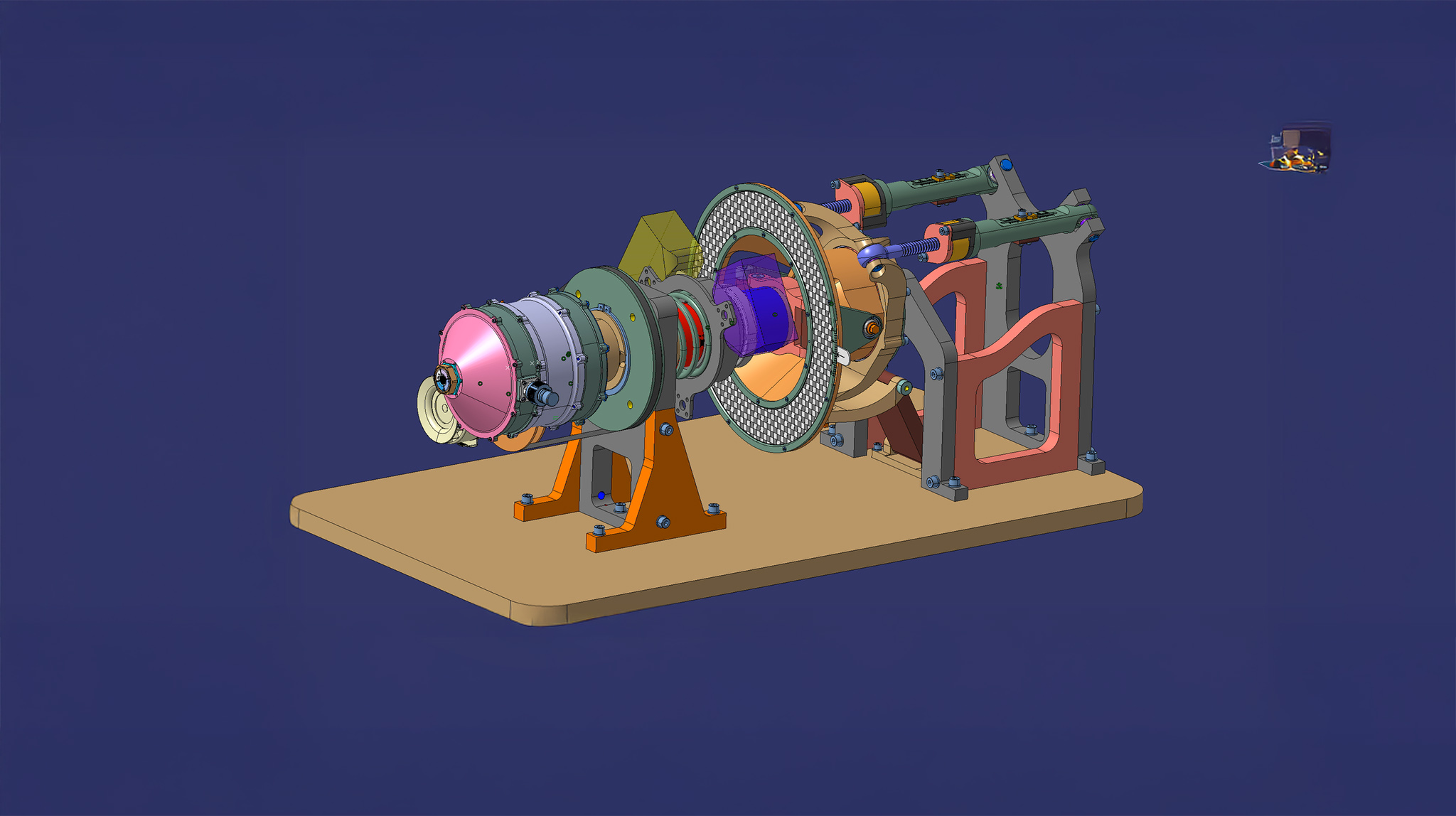

Opening of the Energy to Propulsion Test Facility aftermovie

On 28 November 2025, NLR officially opened the Energy to Propulsion Test Facility (EPTF) at NLR in Marknesse. The EPTF facilitates research to accelerate sustainable propulsion systems of aircraft. The new test facility is an important step in the innovation process. It bridges the gap between scientific research and practical implementation by companies. This unique facility offers researchers from NLR and other knowledge institutions, as well as startups, SMEs, and industrial parties, the opportunity to conduct tests on hydrogen-electric propulsion systems.

28 November 2025

Unique in the EU: Modular EPTF Test Facility for Hydrogen-Powered Flight

With the opening of the Energy to Propulsion Test Facility (EPTF), NLR now operates a unique, modular test facility designed to support research. At present, the focus lies on hydrogen-electric aircraft propulsion. The new facility provides startups, SMEs and industrial partners with optimal conditions to safely and thoroughly test complex innovations in this field. In doing so, NLR contributes to accelerating aviation sustainability.

21 November 2025

Royal NLR partners with Lockheed Martin on airframe repair and life extension capabilities

Royal Netherlands Aerospace Centre will work together with Lockheed Martin on the development of small crack methodologies for airframe lifing over the next three years. In this project LM and NLR will share and exchange technical knowledge and experiences on small crack methodologies applied to laser peening and cold spray technologies

06 June 2025

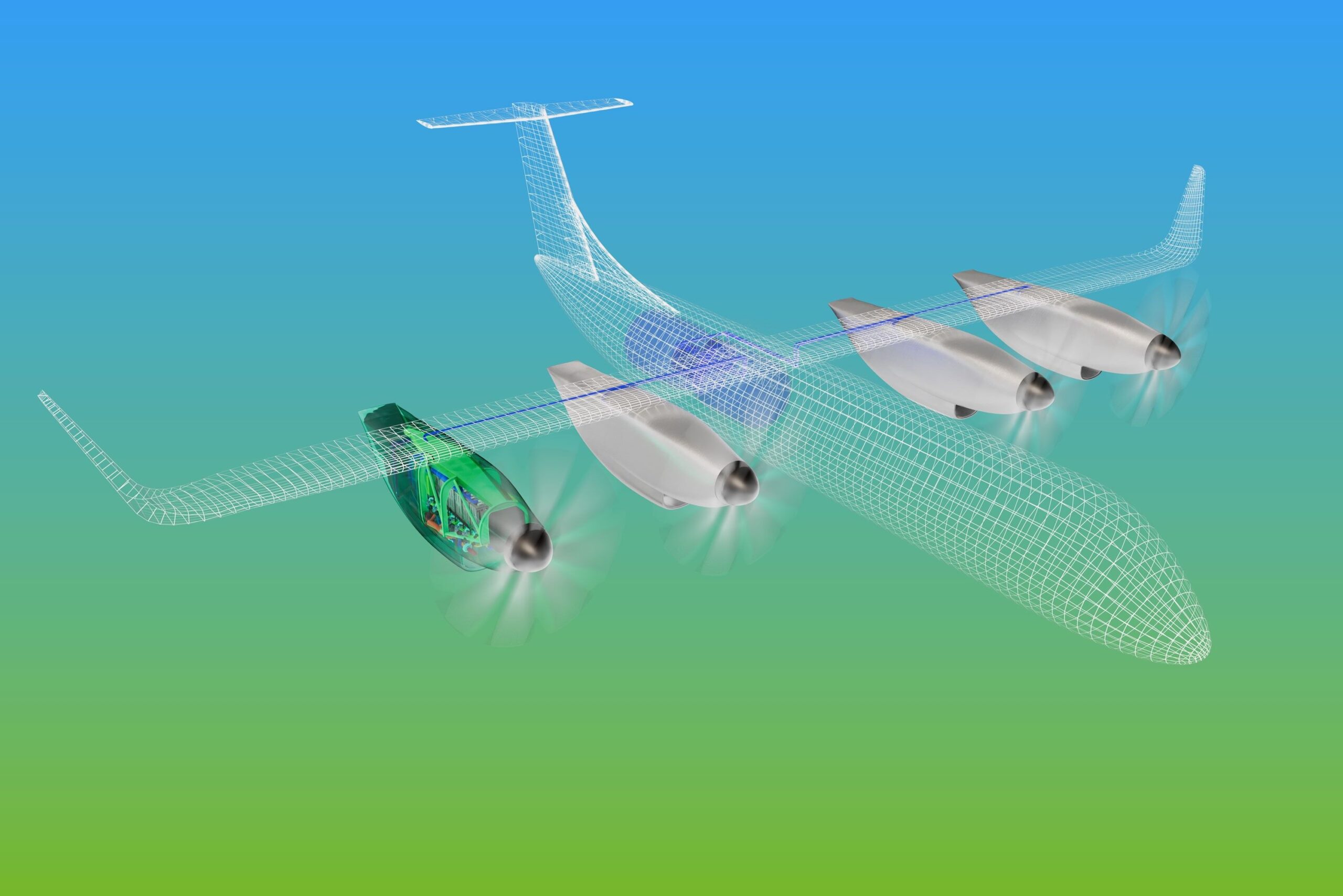

R&D case: Laser ultrasonic inspection of complex-shaped composites

The manufacturing of complex-shaped composites is becoming increasingly common, driving up demand for fast automated quality control. Laser ultrasonic testing can be a viable technique to achieve this, as it is fast and contactless. However, it requires the inspected part to be perpendicular to the laser beam, posing a challenge for the positioning of the laser or part. Combining laser ultrasonics with optical 3D scanning can overcome this challenge and realise a fast automated quality assurance system for composite manufacturing.

28 May 2025

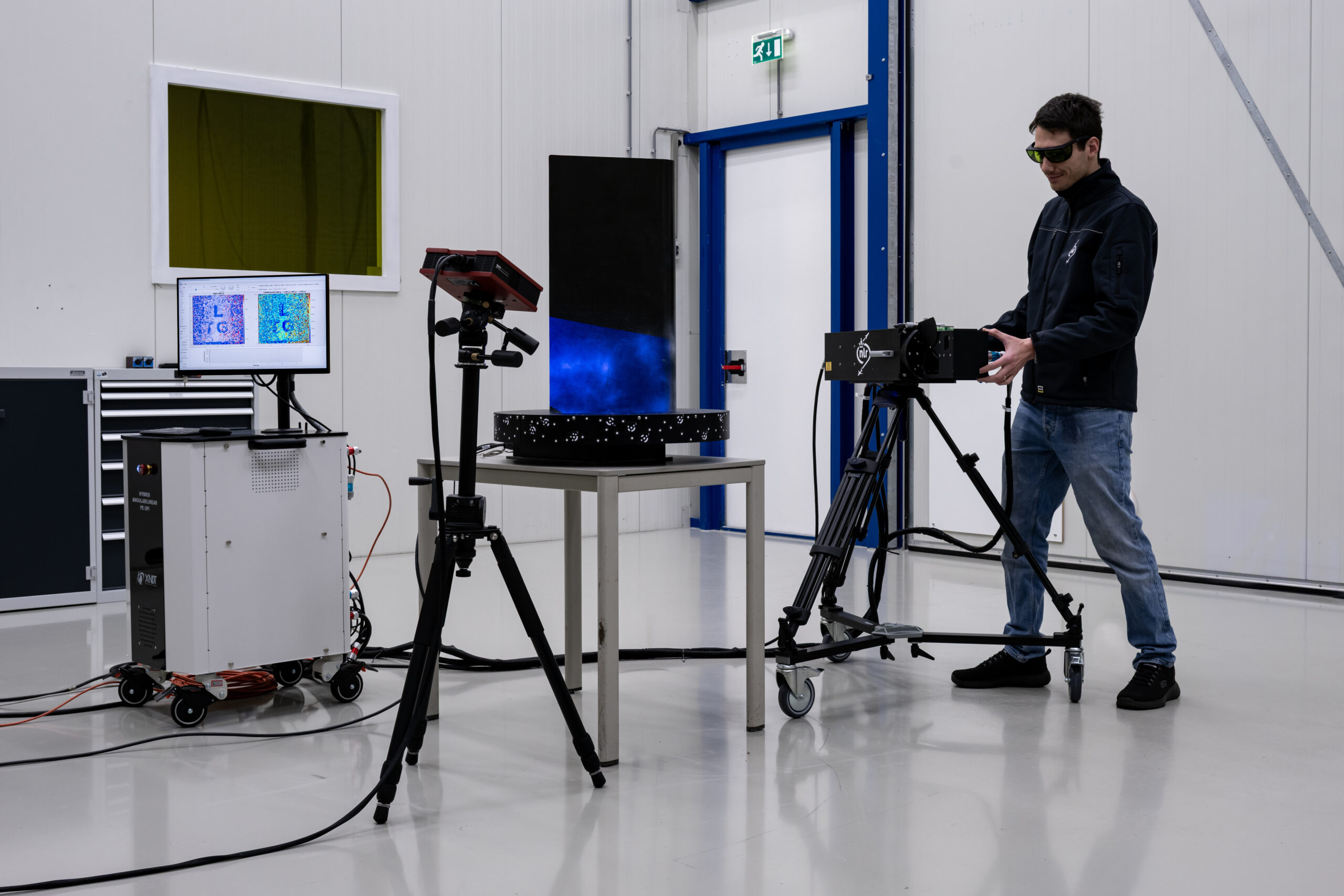

R&D case: Fast non-destructive testing of large composite aircraft structures

Project: PENELOPE (Closed-loop digital pipeline for a flexible and modular manufacturing of large components)

29 April 2025

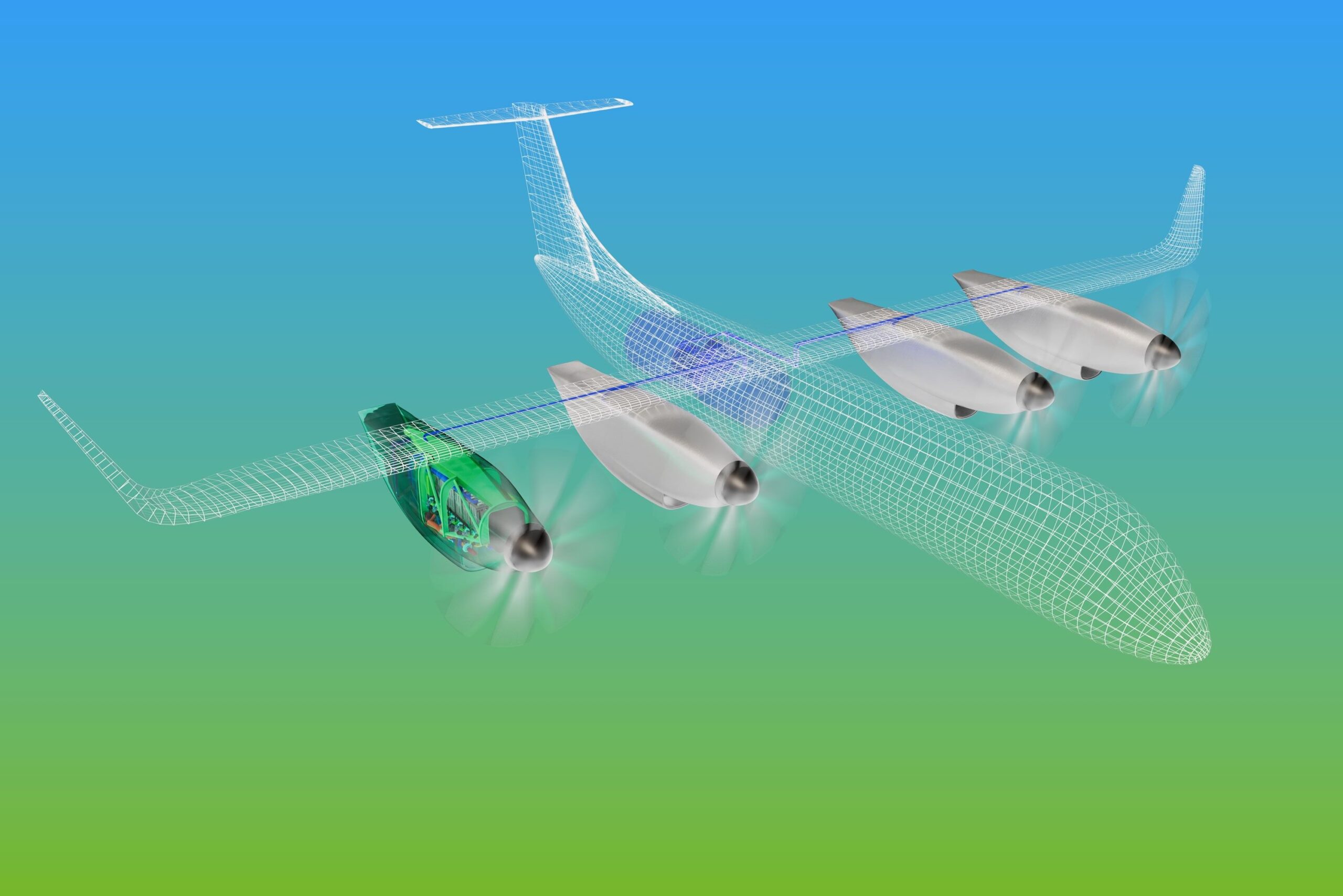

R&D case: FLAPsense

FLAPsense project: optical sensor system for real- time proprotor FLAPping angle monitoring

28 March 2025

Non-Destructive Inspection

Non-destructive inspection (NDI) plays a critical role in ensuring the integrity and reliability of complex systems and components. Our team of scientists and specialists, equipped with novel state-of-the-art facilities, is dedicated to develop and employ tailored inspection methodologies that meet the needs of our clients. We provide assistance to airlines, air forces and aircraft component manufacturers, providing services that span from fundamental research to the qualification of NDI-methods. Our expertise contains a wide variety of NDI-techniques including (laser) ultrasonic testing (UT), eddy current testing (ECT), infrared thermography (IRT), and laser shearography (ST). An overview of our capabilities is displayed in the ‘Non-destructive inspection’ flyer.

28 March 2025

Composite Repair

With a deep understanding of the complexities involved in repairing Polymer Based Composite structures, our team is well-equipped to tackle the most challenging projects. Whether it's thermoset or thermoplastic materials, we possess the expertise and knowledge to deliver high-quality solutions that meet the stringent demands of the 'High Tech - High Spec' community. From aerospace and automotive to maritime, rail, transport, and medical industries, we provide specialised support to organisations that require precision, reliability, and innovation in the repair of composite structures.