The challenge

One of the main challenges of Large Scale 3D printing of high temperature thermoplastics is the control of the interface temperature – which determines the degree of bonding between consecutive layers. When the deposited material has cooled down in excess, poor adhesion is achieved between layers, leading to insufficient strength, delamination, cracking and part failure. If the material has not cooled down sufficiently, it won’t support the consecutive layers, therefore leading to print failure. The interface temperature control is especially important when attempting large scale prints and when processing semicrystalline thermoplastics.

The solution

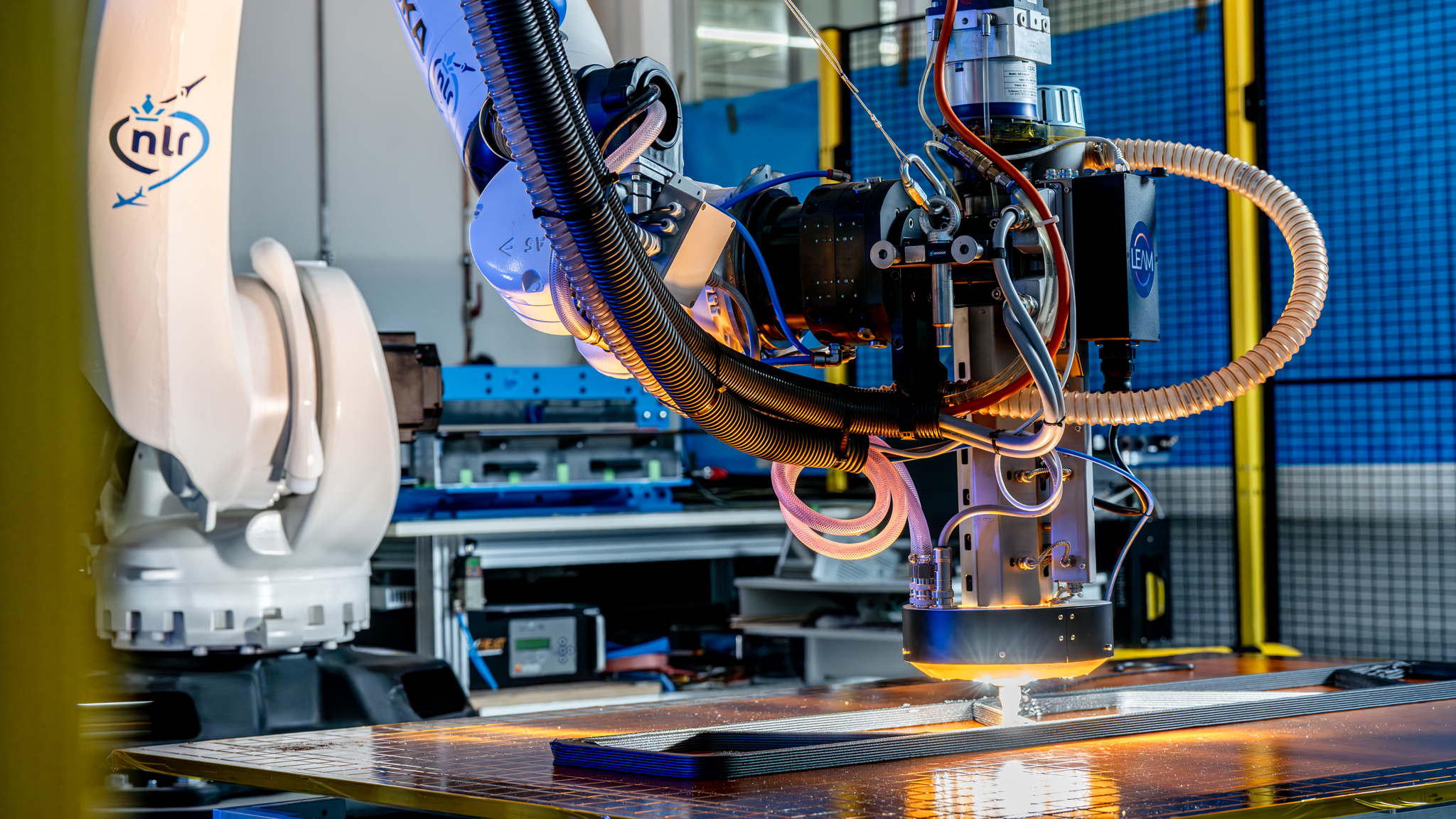

Upgrading the LSAM equipment with the Directed Energy Material Extrusion (DEMEX) system, developed by LEAM, allowed NLR to control and adjust the interface temperature by means of active heating, cooling or adaptive printing speed. This upgrade also paves the way to further exploring new applications, like overprinting. NLR will investigate how to overprint stiffening elements on a substrate (i.e. composite panels) with the use of LSAM.

What did we do?

An equipment upgrade was carried out on the NLR LSAM’s setup, allowing for better temperature control during the printing process, and the effect on the processed material properties were studied to further understand the optimal interface

temperature. To demonstrate the improvement, a large-scale aerospace grade mould is manufactured, achieving five times longer layer length compared to previous experiments, with very high quality and printing stability.

Project partners:

LEAM, Airtech

Acknowledgement: This project is made possible

in part by a contribution from the National Growth

Fund program NXTGEN HIGHTECH